Ac Control

What are some common applications for AC stepping motors ?

AC stepping motors have a wide range of applications due to their precise control and high torque output. Here are some common uses: 1. Printers and Plotters: AC stepping motors are used in printers and plotters to move the print head or pen with precision, and they can control the speed of the print head or pen, allowing for variable printing speeds. 2. CNC Machines: In computer numerical control (CNC) machines, AC stepping motors are used to control the path of the cutting tool and adjust the feed rate of the tool, allowing for precise machining of parts. 3. Robotics: AC stepping motors are often used in robotic joints to provide precise movement and positioning, and they can control the force applied by the robot's end effector, allowing for delicate manipulation of objects. 4. Textile Industry: In textile machinery, AC stepping motors are used to feed fabric through the machine at a controlled rate and control the pattern being woven into the fabric by adjusting the position of the weaving elements. 5. Automation Systems: AC stepping motors are used to control the speed and direction of conveyor belts in automation systems, and they are often used as actuators in automated systems, providing precise control over the position and movement of components.

Can an AC stepping motor be used in robotics applications ?

AC stepping motors can be used in robotics applications, offering precise control and high torque. However, they have speed limitations and can overheat, requiring cooling mechanisms. Consider application requirements and compatibility with control systems before choosing an AC stepping motor for a robotic project.

How do you control the speed and torque of an AC stepping motor ?

The text provides a comprehensive overview of controlling the speed and torque of an AC stepping motor, emphasizing the importance of understanding its basic principles and utilizing appropriate control techniques. Key points include the motor's working principle, torque generation, and step resolution, as well as various control methods such as pulse rate modulation, microstepping, closed-loop control, current limiting, voltage control, and soft start/stop. Practical considerations like drive system compatibility, thermal management, load factors, and safety precautions are also highlighted for optimal motor performance and longevity.

What is an AC stepping motor and how does it work ?

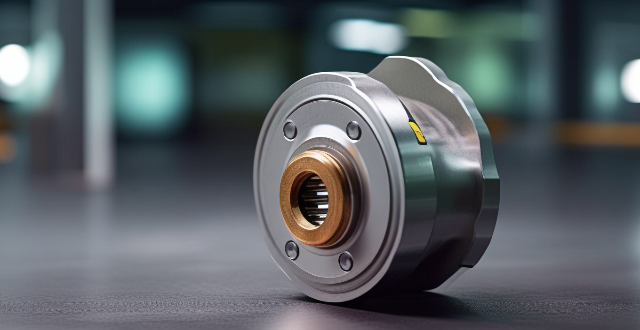

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

What are the advantages of using an AC stepping motor compared to a DC stepping motor ?

The text discusses the advantages of using AC stepping motors compared to DC stepping motors. The main points include: 1. **Simplified Drive Circuitry**: AC stepping motors have simpler drive circuitry than DC stepping motors, leading to fewer components and a more streamlined design, which reduces complexity and lowers manufacturing costs. 2. **Higher Torque Output**: AC stepping motors typically offer higher torque output than DC stepping motors, making them ideal for applications requiring high torque at low speeds. This also leads to improved efficiency and reduced energy consumption. 3. **Better Heat Dissipation**: AC stepping motors often have better heat dissipation capabilities due to their larger surface area and improved cooling mechanisms, allowing them to operate at higher temperatures without overheating and extending their lifespan. 4. **Compatibility with Standard AC Power Sources**: AC stepping motors are compatible with standard AC power sources widely available in industrial and commercial settings, eliminating the need for additional power supplies or conversion equipment and simplifying installation. 5. **Lower Maintenance Requirements**: AC stepping motors generally require less maintenance than DC stepping motors, as they have fewer moving parts and simpler drive circuitry, reducing maintenance costs and downtime. Overall, the text highlights that AC stepping motors offer significant benefits over DC stepping motors in terms of simplicity, performance, efficiency, compatibility, and maintenance, making them a popular choice for various applications where precision control and reliability are essential.

Can you explain the concept of vector control in multi-motor drives ?

Vector control is a method for controlling the speed and torque of electric motors, especially AC motors, in multi-motor drives. It works by decoupling the flux-producing and torque-producing components of the stator current, allowing for independent control of both. This results in improved dynamic response, precise speed regulation, energy efficiency, reduced mechanical stress, and adaptability to different motor types.

Can you explain the differences between AC and DC drive motors ?

Electric motors are essential components in various industries, ranging from manufacturing to transportation. Two of the most common types of electric motors are AC (Alternating Current) and DC (Direct Current) drive motors. While both serve similar functions, there are several differences between them that affect their performance and applications. AC and DC drive motors differ in their construction and design, with AC motors having a simpler design with fewer parts, while DC motors have more complex designs with additional components such as brushes and commutators. This complexity can lead to higher maintenance costs for DC motors compared to AC motors. One of the main differences between AC and DC drive motors is their ability to control speed. AC motors generally operate at a fixed speed, which makes them less suitable for applications requiring variable speed control. On the other hand, DC motors offer precise speed control, making them ideal for applications such as robotics, CNC machines, and conveyor systems. AC motors are generally more efficient than DC motors due to their simpler design and lower power consumption. However, the efficiency of a motor also depends on its size, load capacity, and operating conditions. In some cases, DC motors may be more energy-efficient when used in low-power applications or when precise speed control is required. Another difference between AC and DC drive motors is their starting torque. AC motors generally have a higher starting torque than DC motors, which makes them better suited for heavy-duty applications such as pumps, fans, and compressors. DC motors, on the other hand, provide a smoother start-up but may require additional components to achieve the desired starting torque. The cost and availability of AC and DC drive motors vary depending on their size, type, and manufacturer. Generally, AC motors are more widely available and less expensive than DC motors due to their simpler design and lower production costs. However, the total cost of ownership should also consider factors such as maintenance, repair, and energy consumption over the motor's lifetime.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

What are the key parameters to consider when selecting an AC stepping motor ?

Selecting an AC stepping motor involves considering key parameters such as torque, step angle, voltage and current ratings, resolution, size and weight, compatibility with the control system, and cost. These factors ensure the motor meets the application's requirements, providing enough rotational force, handling load demands, fitting within space and weight restrictions, and operating smoothly and precisely. Compatibility with the controller is crucial for proper operation, while cost considerations help stay within budget constraints.

How do you connect an AC stepping motor to a microcontroller or driver board ?

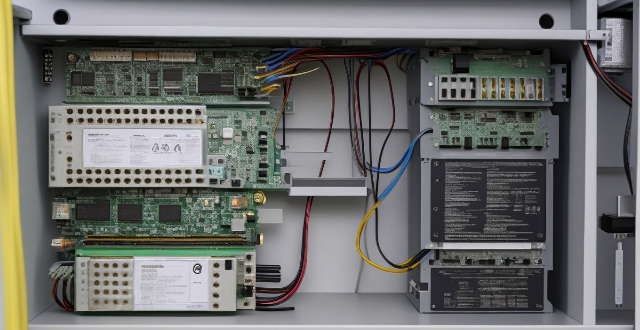

Connecting an AC stepping motor to a microcontroller or driver board involves selecting the right board, connecting the power supply, attaching the motor, programming the board, testing the connection, and troubleshooting any issues. Materials needed include the motor, board, power supply, wires, and optionally a breadboard for temporary connections. Tips include double-checking connections and code, using a breadboard before soldering, and following safety guidelines when working with high voltages.

How do you troubleshoot common issues with AC stepping motors, such as missing steps or low torque ?

Troubleshooting common issues with AC stepping motors involves addressing problems such as missing steps or low torque. This is done by checking the power supply, examining the drive system, analyzing mechanical components, evaluating control signals, and considering environmental factors. It is important to approach the problem methodically, starting with basic checks before moving on to more complex diagnostics.

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

How does temperature control affect food safety ?

This text discusses the impact of temperature control on food safety, emphasizing the risks associated with improper temperature management and the benefits of maintaining appropriate temperatures. It highlights the danger zone for bacterial growth, spoilage due to mold and yeast, and toxin production from bacteria. The article also outlines best practices for temperature control in refrigeration, freezing, cooking, reheating, handling, and storage to ensure food safety.

Why is temperature control important in food storage and preparation ?

Temperature control is crucial in food storage and preparation to ensure safety, quality, and longevity of food products. It prevents bacterial growth, avoids toxin production, maintains flavor and texture, preserves nutrients, extends shelf life, reduces waste, saves energy, and reduces environmental impact. Proper temperature control helps to enjoy delicious and healthy meals while minimizing the risk of foodborne illnesses and food waste.

How does a combination motor drive work ?

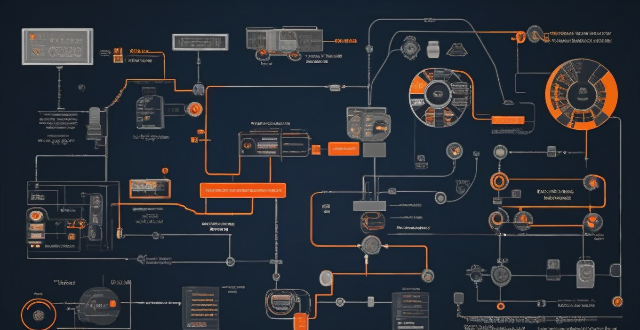

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

How can I customize the Control Center on my iPhone for quick access to frequently used functions ?

Customizing the Control Center on an iPhone allows for quick access to frequently used functions. To do this, open the Settings app and navigate to the Control Center settings. Here, you can add or remove controls from the Control Center and rearrange their order. After making your changes, test them by opening the Control Center. Additional tips include adding accessibility features, an Apple TV remote, Low Power Mode, and a screen recording control for convenience.

What is a speed controller and how does it work ?

Speed controllers regulate the speed of electric motors and are used in various applications requiring precise speed control, such as industrial machinery. They consist of an input stage for power supply, a control stage using PID controllers to adjust voltage based on motor speed feedback, and an output stage that converts adjusted voltage for motor use.

What role do dams play in flood control ?

Dams are crucial for flood control, providing storageDams are crucial for flood control, providing storage reduction, community preparedness, providing storage, flow regulation, risk reduction, community preparedness, ecological health support, and integrated water resource management.

What role do wetlands play in water purification and flood control ?

In summary, wetlands are crucial ecosystems that play a vital role in water purification and flood control. They act as natural filters, removing sediments, nutrients, and pollutants from water while also providing buffering capacity for floodwaters. By preserving and restoring wetlands, we can ensure clean water resources and minimize the risks associated with flooding.

How can I customize the control center in my Apple device ?

Customizing the Control Center on your Apple device is a straightforward process that allows you to tailor the panel to your preferences and needs. Here's how you can do it: On an iPhone or iPod Touch: 1. Open the Settings App and access Control Center Options within the app. 2. Customize Controls by removing or adding controls in the "Control Center" and "Include" sections. 3. Rearrange Controls by tapping and holding the grip handle and dragging it up or down within the list. 4. Add and Remove Controls as needed from the "Include" and "Control Center" sections. 5. Access and Use the Control Center by swiping down from the top-right corner of your screen. On an iPad: 1. Open the Settings App and navigate to Control Center Settings. 2. Customize Your Controls by removing or adding controls in the "Control Center" and "Include" sections. 3. Arrange Controls to Your Liking by tapping and holding the grip handle next to a control in the list, then dragging it to your desired position. 4. Include Additional Controls from the "Include" section. 5. Remove Unnecessary Controls from the main "Control Center" section. 6. Access the Revamped Control Center by swiping down from the top-right corner of your screen.

In what ways do sports promote self-discipline and self-control ?

Sports play a crucial role in promoting self-discipline and self-control by teaching goal setting, time management, perseverance, impulse control, delayed gratification, and stress management. These skills are essential for success in all areas of life, including personal and professional relationships, academics, and careers. By participating in sports, individuals develop valuable character traits that can lead to long-term success and well-being.

How do I negotiate terms with an investor without giving away too much control ?

Negotiating terms with an investor requires careful consideration and planning. Here are some tips on how to negotiate terms with an investor without giving away too much control: 1. Understand your value proposition: Before entering into any negotiations, it's essential to understand the value of your business. This includes knowing your company's strengths, weaknesses, opportunities, and threats (SWOT analysis). 2. Set clear expectations: It's crucial to set clear expectations from the outset of the negotiation process. This means being upfront about what you're willing to give up and what you're not. 3. Focus on long-term goals: When negotiating with an investor, keep your long-term goals in mind. Consider how the terms of the investment will impact your business in the future and whether they align with your long-term vision. 4. Be willing to walk away: If an investor is asking for too much control or making unreasonable demands, don't be afraid to walk away from the deal. Remember that there are other investors out there who may be more willing to work with you on terms that suit both parties. 5. Seek legal advice: Before finalizing any agreements with an investor, seek legal advice. A lawyer can help you understand the implications of the terms being proposed and ensure that your interests are protected.

What are the different types of speed controllers available in the market ?

Speed controllers are devices used to regulate the speed of electric motors. They are essential in various industries, including manufacturing, transportation, and energy production. The main types of speed controllers are Eddy Current Drives, DC Drives, AC Drives, and Variable Frequency Drives (VFDs). Each type has its own advantages and disadvantages, such as precise speed control, high efficiency, low maintenance requirements, high initial cost, limited torque capacity, high starting torque, good dynamic response, limited lifespan due to brush wear, low initial cost, long lifespan, wide range of sizes and configurations, less precise speed control compared to DC drives, limited torque capacity at low speeds, energy-efficient operation, sensitive to electrical noise and disturbances. The choice of speed controller depends on the specific application requirements, such as precision, efficiency, and cost.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

What is the efficiency of an electromagnetic motor compared to other types of motors ?

This article compares the efficiency of an electromagnetic motor with other types of motors such as DC motors, AC motors, stepper motors, and servo motors. Electromagnetic motors have a high efficiency rate, typically ranging from 80% to 95%, making them suitable for applications where energy consumption is a concern. DC motors have lower efficiency rates, typically around 50% to 70%, while AC motors have higher efficiency rates, up to 95% or more, but are generally less efficient than electromagnetic motors due to losses in the windings and core. Stepper motors have relatively low efficiency rates compared to other types of motors, typically around 30% to 50%, while servo motors have moderate efficiency rates, typically around 60% to 80%. Overall, the choice of motor depends on various factors such as cost, size, weight, and required performance characteristics.

How can I choose the right combination motor drive for my application ?

When selecting a combination motor drive for your application, consider factors such as the type of motor (AC, DC, stepper, or servo), application requirements (load characteristics, speed and torque needs, control precision), appropriate drive technology (VFDs, electronic speed controls, stepper motor drives, servo amplifiers), compatibility and integration with existing systems, performance features (efficiency, dynamic response, protection features), budget and cost considerations (initial and operating costs), and seek professional advice from manufacturers and technical support.

What are the different types of electromagnetic motors ?

This article discusses the various types of electromagnetic motors, including DC motors (brushed and brushless), AC motors (induction and synchronous), stepper motors (bipolar and unipolar), and servo motors (DC and AC). Each type of motor has unique features and applications, such as power demand, speed range, accuracy, and cost. The choice of motor depends on the specific requirements of the application.