Ac Used

What are some common applications for AC stepping motors ?

AC stepping motors have a wide range of applications due to their precise control and high torque output. Here are some common uses: 1. Printers and Plotters: AC stepping motors are used in printers and plotters to move the print head or pen with precision, and they can control the speed of the print head or pen, allowing for variable printing speeds. 2. CNC Machines: In computer numerical control (CNC) machines, AC stepping motors are used to control the path of the cutting tool and adjust the feed rate of the tool, allowing for precise machining of parts. 3. Robotics: AC stepping motors are often used in robotic joints to provide precise movement and positioning, and they can control the force applied by the robot's end effector, allowing for delicate manipulation of objects. 4. Textile Industry: In textile machinery, AC stepping motors are used to feed fabric through the machine at a controlled rate and control the pattern being woven into the fabric by adjusting the position of the weaving elements. 5. Automation Systems: AC stepping motors are used to control the speed and direction of conveyor belts in automation systems, and they are often used as actuators in automated systems, providing precise control over the position and movement of components.

Can an AC stepping motor be used in robotics applications ?

AC stepping motors can be used in robotics applications, offering precise control and high torque. However, they have speed limitations and can overheat, requiring cooling mechanisms. Consider application requirements and compatibility with control systems before choosing an AC stepping motor for a robotic project.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

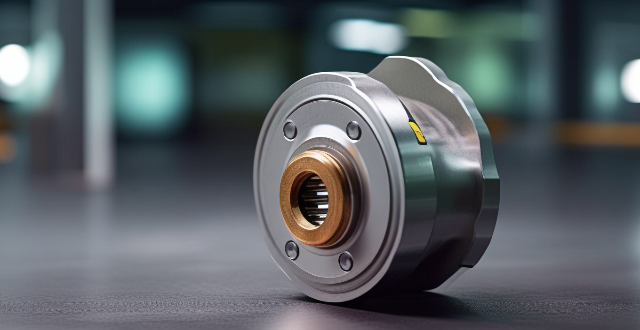

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

What are the advantages of using an AC stepping motor compared to a DC stepping motor ?

The text discusses the advantages of using AC stepping motors compared to DC stepping motors. The main points include: 1. **Simplified Drive Circuitry**: AC stepping motors have simpler drive circuitry than DC stepping motors, leading to fewer components and a more streamlined design, which reduces complexity and lowers manufacturing costs. 2. **Higher Torque Output**: AC stepping motors typically offer higher torque output than DC stepping motors, making them ideal for applications requiring high torque at low speeds. This also leads to improved efficiency and reduced energy consumption. 3. **Better Heat Dissipation**: AC stepping motors often have better heat dissipation capabilities due to their larger surface area and improved cooling mechanisms, allowing them to operate at higher temperatures without overheating and extending their lifespan. 4. **Compatibility with Standard AC Power Sources**: AC stepping motors are compatible with standard AC power sources widely available in industrial and commercial settings, eliminating the need for additional power supplies or conversion equipment and simplifying installation. 5. **Lower Maintenance Requirements**: AC stepping motors generally require less maintenance than DC stepping motors, as they have fewer moving parts and simpler drive circuitry, reducing maintenance costs and downtime. Overall, the text highlights that AC stepping motors offer significant benefits over DC stepping motors in terms of simplicity, performance, efficiency, compatibility, and maintenance, making them a popular choice for various applications where precision control and reliability are essential.

Can you explain the differences between AC and DC drive motors ?

Electric motors are essential components in various industries, ranging from manufacturing to transportation. Two of the most common types of electric motors are AC (Alternating Current) and DC (Direct Current) drive motors. While both serve similar functions, there are several differences between them that affect their performance and applications. AC and DC drive motors differ in their construction and design, with AC motors having a simpler design with fewer parts, while DC motors have more complex designs with additional components such as brushes and commutators. This complexity can lead to higher maintenance costs for DC motors compared to AC motors. One of the main differences between AC and DC drive motors is their ability to control speed. AC motors generally operate at a fixed speed, which makes them less suitable for applications requiring variable speed control. On the other hand, DC motors offer precise speed control, making them ideal for applications such as robotics, CNC machines, and conveyor systems. AC motors are generally more efficient than DC motors due to their simpler design and lower power consumption. However, the efficiency of a motor also depends on its size, load capacity, and operating conditions. In some cases, DC motors may be more energy-efficient when used in low-power applications or when precise speed control is required. Another difference between AC and DC drive motors is their starting torque. AC motors generally have a higher starting torque than DC motors, which makes them better suited for heavy-duty applications such as pumps, fans, and compressors. DC motors, on the other hand, provide a smoother start-up but may require additional components to achieve the desired starting torque. The cost and availability of AC and DC drive motors vary depending on their size, type, and manufacturer. Generally, AC motors are more widely available and less expensive than DC motors due to their simpler design and lower production costs. However, the total cost of ownership should also consider factors such as maintenance, repair, and energy consumption over the motor's lifetime.

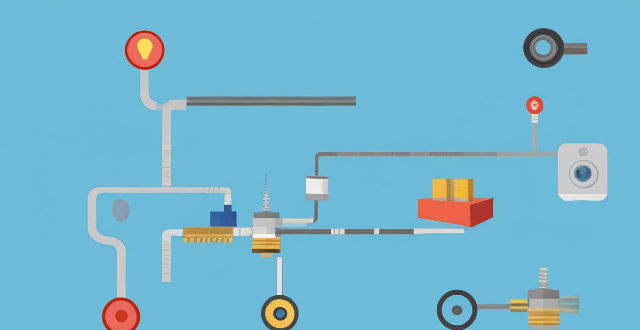

How do you control the speed and torque of an AC stepping motor ?

The text provides a comprehensive overview of controlling the speed and torque of an AC stepping motor, emphasizing the importance of understanding its basic principles and utilizing appropriate control techniques. Key points include the motor's working principle, torque generation, and step resolution, as well as various control methods such as pulse rate modulation, microstepping, closed-loop control, current limiting, voltage control, and soft start/stop. Practical considerations like drive system compatibility, thermal management, load factors, and safety precautions are also highlighted for optimal motor performance and longevity.

What are the key parameters to consider when selecting an AC stepping motor ?

Selecting an AC stepping motor involves considering key parameters such as torque, step angle, voltage and current ratings, resolution, size and weight, compatibility with the control system, and cost. These factors ensure the motor meets the application's requirements, providing enough rotational force, handling load demands, fitting within space and weight restrictions, and operating smoothly and precisely. Compatibility with the controller is crucial for proper operation, while cost considerations help stay within budget constraints.

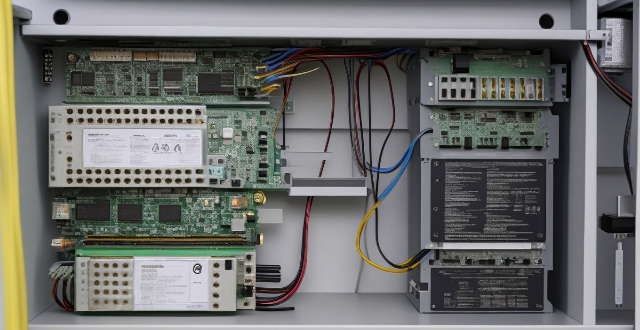

How do you connect an AC stepping motor to a microcontroller or driver board ?

Connecting an AC stepping motor to a microcontroller or driver board involves selecting the right board, connecting the power supply, attaching the motor, programming the board, testing the connection, and troubleshooting any issues. Materials needed include the motor, board, power supply, wires, and optionally a breadboard for temporary connections. Tips include double-checking connections and code, using a breadboard before soldering, and following safety guidelines when working with high voltages.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

How do you troubleshoot common issues with AC stepping motors, such as missing steps or low torque ?

Troubleshooting common issues with AC stepping motors involves addressing problems such as missing steps or low torque. This is done by checking the power supply, examining the drive system, analyzing mechanical components, evaluating control signals, and considering environmental factors. It is important to approach the problem methodically, starting with basic checks before moving on to more complex diagnostics.

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

What materials are used to make durable iPhone cases ?

Durable iPhone cases are designed to protect your device from drops, scratches, and other types of damage. The materials used to make these cases play a crucial role in determining their durability and effectiveness. In this article, we will explore the different materials used to make durable iPhone cases and discuss their benefits and drawbacks.

Can a single motor drive be used for heavy-duty tasks ?

A single motor drive can indeed be used for heavy-duty tasks, but it depends on several factors such as the type of motor, its power rating, and the nature of the task. There are various types of motors available, each with its own set of advantages and disadvantages. The power rating of a motor is an important factor to consider when determining whether it can handle heavy-duty tasks. The nature of the task is another critical factor to consider. By carefully considering these factors and choosing the right motor for the job, you can ensure that your system is reliable, efficient, and effective.

What are the different types of speed controllers available in the market ?

Speed controllers are devices used to regulate the speed of electric motors. They are essential in various industries, including manufacturing, transportation, and energy production. The main types of speed controllers are Eddy Current Drives, DC Drives, AC Drives, and Variable Frequency Drives (VFDs). Each type has its own advantages and disadvantages, such as precise speed control, high efficiency, low maintenance requirements, high initial cost, limited torque capacity, high starting torque, good dynamic response, limited lifespan due to brush wear, low initial cost, long lifespan, wide range of sizes and configurations, less precise speed control compared to DC drives, limited torque capacity at low speeds, energy-efficient operation, sensitive to electrical noise and disturbances. The choice of speed controller depends on the specific application requirements, such as precision, efficiency, and cost.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

What is the efficiency of an electromagnetic motor compared to other types of motors ?

This article compares the efficiency of an electromagnetic motor with other types of motors such as DC motors, AC motors, stepper motors, and servo motors. Electromagnetic motors have a high efficiency rate, typically ranging from 80% to 95%, making them suitable for applications where energy consumption is a concern. DC motors have lower efficiency rates, typically around 50% to 70%, while AC motors have higher efficiency rates, up to 95% or more, but are generally less efficient than electromagnetic motors due to losses in the windings and core. Stepper motors have relatively low efficiency rates compared to other types of motors, typically around 30% to 50%, while servo motors have moderate efficiency rates, typically around 60% to 80%. Overall, the choice of motor depends on various factors such as cost, size, weight, and required performance characteristics.

What are the most common materials used in the production of protective clothing ?

Protective clothing is designed to safeguard individuals from hazardous environments or conditions. The materials used for such garments play a crucial role in providing the necessary protection while ensuring comfort and functionality. In this article, we will explore the most common materials used in the production of protective clothing: Polyester, Cotton, Nylon, Neoprene, and Gore-Tex.

What currencies can be used for Cross-Border Payment ?

The currencies used for cross-border payments vary widely depending on numerous factors, including economic strength, political stability, and market acceptance. Major world currencies like the US Dollar, Euro, British Pound Sterling, and Japanese Yen are commonly used due to their global acceptance and role in international trade and financial markets. Other currencies such as the Chinese Yuan/Renminbi, Canadian Dollar, and Australian Dollar also play significant roles in cross-border payments, particularly in commodities trade and regional economies. Digital currencies, including Bitcoin and stablecoins, are increasingly being used for cross-border payments, offering decentralized transactions and the benefits of blockchain technology. Factors influencing currency choice include regulatory environment, cost considerations, market fluctuations, and business agreements.

What are the different types of electromagnetic motors ?

This article discusses the various types of electromagnetic motors, including DC motors (brushed and brushless), AC motors (induction and synchronous), stepper motors (bipolar and unipolar), and servo motors (DC and AC). Each type of motor has unique features and applications, such as power demand, speed range, accuracy, and cost. The choice of motor depends on the specific requirements of the application.

What are the basic techniques used in Chinese cooking ?

Chinese cuisine is known for its diverse flavors and cooking techniques. Here are some of the basic techniques used in Chinese cooking: 1. Stir-frying involves quickly frying small pieces of food in a wok or frying pan over high heat. The key to successful stir-frying is to use hot oil, fresh ingredients, and constant motion to prevent burning. 2. Steaming involves placing food in a steamer basket over boiling water and allowing it to cook through steam. This method is often used for dumplings, buns, fish, and vegetables. 3. Braising is a slow-cooking method that involves simmering meat or vegetables in liquid until they become tender and flavorful. This technique is often used for stews, soups, and braises. 4. Deep-frying involves submerging food in hot oil until it becomes crispy and golden brown. This technique is often used for fried rice, spring rolls, and tempura dishes. 5. Roasting involves cooking food in an oven at high temperatures until it becomes caramelized and tender. This technique is often used for roasted meats, vegetables, and baked goods like mooncakes and egg tarts.

Can an electronic speed controller be used in a car engine ?

The question of whether an electronic speed controller (ESC) can be used in a car engine depends on the type of engine. In traditional internal combustion engines (ICE), which use gasoline or diesel as fuel, an ESC cannot be used because these engines rely on mechanical systems for speed control. However, in electric cars, which use electric motors as their primary source of propulsion, an ESC is essential for controlling the speed of the motor and protecting it from damage. Therefore, while an ESC cannot be used in ICE vehicles, it plays a crucial role in electric vehicles.

Can you still get a good deal on a used hybrid car ?

The text discusses whether it is still possible to get a good deal on a used hybrid car, considering factors such as depreciation rates, technological advancements, fuel prices, and environmental concerns. It outlines the pros and cons of buying a used hybrid car and provides tips for getting a good deal. The conclusion states that while the market is subject to various dynamics, it is still possible to find a good deal on a used hybrid car by employing smart buying strategies.

Has religion ever been used to justify discrimination in sports ?

Religion has been used to justify discrimination in sports, including apartheid in South Africa, Islamic veiling and swimming, and caste-based discrimination in India. Contemporary issues include Sikh turbans and safety regulations, and Jewish holidays and scheduling conflicts. Addressing these issues requires a balance between respect for religious freedom and principles of equality and fairness in sports.

What new materials are being used in the production of sports equipment ?

The sports industry is constantly evolving, and with that evolution comes the introduction of new materials used in the production of sports equipment. These materials are designed to enhance performance, increase durability, and improve safety for athletes. Some of the latest materials being used in sports equipment production include carbon fiber, titanium, aerogel, Kevlar, and polyurethane foam. Carbon fiber is lightweight yet incredibly strong, making it ideal for use in items such as bicycle frames, tennis rackets, and golf clubs. Titanium is lightweight, corrosion-resistant, and extremely durable. Aerogel is incredibly light yet strong enough to support significant weight. Kevlar is known for its exceptional strength and heat resistance. Polyurethane foam provides excellent cushioning and shock absorption properties. As technology advances and athletes demand better performance from their gear, we can expect to see even more innovative materials being developed and incorporated into sports equipment production.

How is artificial intelligence being used to create new forms of entertainment ?

Artificial intelligence (AI) is revolutionizing the entertainment industry by creating new forms of entertainment that were not possible before. AI has enabled the development of personalized and interactive experiences that engage audiences in ways never seen before. Here are some examples of how AI is being used to create new forms of entertainment: 1. Personalization: AI algorithms are being used to personalize entertainment content for individual users. For example, streaming services like Netflix and Amazon Prime use AI to recommend movies and TV shows based on a user's viewing history and preferences. 2. Interactive Experiences: AI-powered virtual assistants and chatbots are being used to create interactive experiences that allow users to engage with entertainment content in new ways. For example, the game "Detroit: Become Human" uses an AI-powered system to allow players to interact with characters in the game in a natural and realistic way. 3. Content Creation: AI is also being used to create new forms of entertainment content. For example, AI-generated music and art are becoming increasingly popular. AI algorithms can analyze existing music and art to create new pieces that are unique and original. 4. Gaming: AI is being used to enhance gaming experiences by creating more realistic and challenging gameplay. For example, AI-powered non-player characters (NPCs) can behave more realistically and adapt to a player's actions, making the game more engaging and challenging. 5. Virtual Reality and Augmented Reality: AI is being used to create more immersive virtual reality (VR) and augmented reality (AR) experiences. For example, AI algorithms can track a user's movements and adjust the VR or AR environment in real-time to create a more realistic and engaging experience. In conclusion, AI is being used to create new forms of entertainment that are more personalized, interactive, and engaging than ever before. From personalized recommendations to AI-generated content, the possibilities for AI in the entertainment industry are endless. As AI technology continues to evolve, we can expect even more innovative and exciting forms of entertainment to emerge.

How does solar power work and is it a viable option for homes ?

Solar power is generated through solar panels made of silicon cells that convert sunlight into direct current (DC) electricity. This process involves absorption of light, conversion to DC, conversion to alternating current (AC), and distribution throughout a home or business. Solar power is a viable option for homes due to its renewable nature, cost savings, environmental benefits, and government incentives. However, weather conditions, storage options, and upfront costs should also be considered before deciding if solar power is the right choice for your home.

What are the most effective anti-aging products used by celebrities ?

The most effective anti-aging products used by celebrities include retinol, hyaluronic acid, vitamin C, and sunscreen. Retinol reduces the appearance of fine lines and wrinkles, while hyaluronic acid provides intense hydration and plumps up the skin. Vitamin C brightens skin tone and protects against environmental damage, and sunscreen is essential for preventing premature aging caused by sun damage. By incorporating these products into your skincare routine, you can enjoy younger-looking skin like celebrities do.