Chemical Speed

What safety precautions should be taken while working with a speed controller ?

Working with a speed controller can be dangerous if proper safety precautions are not taken. Here are some important safety measures to consider: ## General Safety Tips - Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and hearing protection when working with a speed controller. - Ensure that the work area is well-lit and free from any tripping or slipping hazards. - Keep all tools and materials organized and stored safely to prevent accidents. - Be aware of your surroundings and any potential hazards that may exist in the work environment. ## Electrical Safety - Disconnect power to the speed controller before performing any maintenance or repairs. - Use insulated tools when working on electrical components. - Avoid touching exposed wires or terminals with bare hands. - Do not work on a speed controller if you are standing on a damp or wet surface. ## Mechanical Safety - Use appropriate lockout/tagout procedures to prevent accidental startup of machinery during maintenance or repair. - Ensure that guards and shields are in place and functioning properly. - Be cautious around moving parts and avoid reaching across or under moving machinery. - Use caution when handling heavy objects to avoid straining muscles or causing injury. ## Chemical Safety - If chemicals are used in conjunction with the speed controller, ensure proper ventilation is provided. - Store chemicals in their original containers and keep them away from heat sources or open flames. - Follow all manufacturer instructions for handling and disposal of chemicals.

What are the best practices for chemical protection in a laboratory setting ?

The text provides best practices for chemical protection in a laboratory setting, including wearing appropriate personal protective equipment, proper storage and handling of chemicals, using proper ventilation, having a spill response plan, disposing of waste properly, and staying informed and trained. These practices are crucial to ensure the safety of individuals working with hazardous chemicals in a lab environment.

How do flow batteries compare to traditional chemical batteries ?

Flow batteries and traditional chemical batteries are both used for energy storage, but differ in aspects such as energy storage mechanism, power and energy density, lifespan and maintenance, and cost and scalability. Traditional chemical batteries store energy through chemical reactions within cells and have a fixed capacity, while flow batteries use external tanks of electrolyte solutions and have adjustable capacity. Traditional chemical batteries can deliver high power output per unit weight or volume and have moderate energy density, while flow batteries typically have lower power density but higher energy density. Traditional chemical batteries have a limited number of charge and discharge cycles before performance degrades and require regular maintenance, while flow batteries can undergo a larger number of cycles without significant degradation and require less maintenance. Traditional chemical batteries often have higher upfront costs and limited scalability, while flow batteries generally have lower upfront costs and offer more flexibility in scaling up. The choice between the two depends on the specific requirements of the energy storage application.

How do hazmat suits provide protection against chemical exposure ?

Hazmat suits, also known as chemical protective clothing or chemical resistant suits, are specialized garments designed to protect wearers from hazardous materials. These suits offer a high level of protection against chemical exposure by creating a barrier between the wearer and the environment. The key features of hazmat suits include their material, design, breathability, and comfort. The article discusses how hazmat suits provide protection against chemical exposure in detail, including the levels of protection offered by different types of suits.

How does PPE protect against chemical exposure in industrial settings ?

In industrial environments, workers are often exposed to hazardous chemicals that can pose significant health risks. Personal Protective Equipment (PPE) plays a crucial role in safeguarding these workers from potential harm. This article delves into the various types of PPE and how they protect against chemical exposure. Types of PPE for Chemical Protection include respiratory protection such as filtering facepiece respirators, powered air-purifying respirators, and self-contained breathing apparatuses; skin and eye protection like chemical-resistant gloves, aprons and suits, and goggles and face shields; and foot protection like chemical-resistant boots. PPE works against chemicals by forming a physical barrier between the worker and the chemical, absorbing or adsorbing chemicals before they reach the user, and isolating the user completely from the external environment. Best practices for using PPE include ensuring proper fit and comfort, regular inspection and maintenance, and comprehensive training and education on how to use PPE effectively. The correct use of PPE is essential for the safety of workers in industries where chemical exposure is a risk. Employers must ensure that appropriate PPE is provided, maintained, and used correctly to create a safer work environment.

How often should chemical protective gear be replaced or maintained ?

Chemical protective gear is essential for workers exposed to hazardous chemicals. The frequency of replacement or maintenance depends on the type of gear, level of exposure, and manufacturer's recommendations. Regular visual inspections and testing are crucial to ensure that the gear remains effective and safe. By following the manufacturer's guidelines, workers can minimize their risk of exposure to hazardous chemicals and protect their health and well-being.

Can you explain the different levels of chemical resistance in protective clothing ?

Chemical resistance is a crucial aspect of protective clothing, especially for those working in hazardous environments. The level of chemical resistance required depends on the type and concentration of chemicals present in the work area. Here, we will discuss the different levels of chemical resistance in protective clothing: 1. Level A: Highest Level of Protection 2. Level B: Intermediate Level of Protection 3. Level C: Lower Level of Protection 4. Level D: Basic Protection

In what scenarios is it necessary to use chemical protective measures in an industrial setting ?

Industrial settings often require chemical protective measures to ensure worker safety. These scenarios include handling hazardous chemicals, working in confined spaces, performing maintenance on chemical process equipment, disposing of hazardous waste, and emergency response to chemical incidents. Workers must wear appropriate personal protective equipment (PPE) such as gloves, aprons, goggles, and respiratory protection devices to prevent exposure to harmful chemicals. Examples of these scenarios include manufacturing processes involving strong acids or bases, tank cleaning in the petrochemical industry, repairing valves or pipes in chemical processing plants, disposal of chemical waste at landfill sites, and firefighting and rescue operations during chemical fires or explosions. By implementing these chemical protective measures in relevant industrial scenarios, employers can help safeguard their employees from potential health hazards associated with chemical exposure.

What is the role of respirators in chemical protection, and how are they classified ?

Respirators play a crucial role in chemical protection by filtering out harmful particles and chemicals from the air. They are designed to protect workers from inhaling toxic substances, such as gases, vapors, and particulate matter, that may be present in their work environment. Respirators are essential for ensuring worker safety and preventing respiratory diseases caused by exposure to hazardous chemicals. Respirators can be classified into two main categories based on their design and function: air-purifying respirators (APRs) and atmosphere-supplying respirators (ASRs). APRs remove contaminants from the air before it is inhaled, while ASRs provide clean air from an external source through a hose or pipeline. When selecting a respirator for chemical protection, several factors must be considered, including the type of hazard, level of protection required, fit and comfort, and maintenance and care. By understanding the different types of respirators and selecting the appropriate one based on the specific hazard, employers can help ensure the safety and health of their employees.

What is the importance of understanding material safety data sheets (MSDS) in chemical handling and protection ?

The text discusses the importance of understanding Material Safety Data Sheets (MSDS) in chemical handling and protection. It explains what an MSDS is, its significance for health and safety, compliance with regulations, environmental protection, and risk management. The article emphasizes that understanding MSDS is crucial for workers and employers to ensure a safe and healthy work environment.

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

How does speed reading affect comprehension ?

Speed reading is a technique used to read text faster while maintaining or improving comprehension. However, the impact of speed reading on comprehension can vary depending on several factors such as the individual's reading skills, the difficulty level of the material, and the method used for speed reading. In this article, we will explore how speed reading affects comprehension and provide some tips to improve both speed and understanding.

What is the maximum speed of Wi-Fi 6 ?

Wi-Fi 6, the latest wireless networking standard, offers significant improvements in speed, capacity, and efficiency over its predecessors. The maximum speed of Wi-Fi 6 can reach up to 9.6 Gbps per channel under ideal conditions, thanks to features such as higher data rates, OFDMA, MU-MIMO, BSS Coloring, Target Wake Time, and 1024-QAM. However, real-world performance may vary depending on various factors, and users can expect speeds ranging from several hundred Mbps to a few Gbps in practical scenarios.

What is an electronic speed controller ?

The text provides an overview of electronic speed controllers (ESCs), which are devices used to regulate the power sent to motors in model aircraft and drones. It describes key features such as adjustable throttle, battery protection, signal modulation, and failsafe functionality. The process by which ESCs work is outlined: receiving a signal from the radio transmitter, decoding it into a throttle setting, controlling motor speed based on this setting, and providing feedback to the pilot. Two types of ESCs are mentioned: brushed and brushless, with the latter being more complex and expensive. The text concludes that ESCs are crucial for precise control over motor speed and aircraft performance.

How does a PID (Proportional Integral Derivative) controller differ from other types of speed controllers ?

A PID controller uses three control mechanisms to adjust output based on input error, differing from other speed controllers in flexibility and adaptability.

How do speed limits affect traffic safety ?

Speed limits are crucial components of traffic safety. They serve as a tool to control the speed of vehicles on the road, thereby reducing the risk of accidents and fatalities. In this article, we will discuss how speed limits affect traffic safety in detail. Importance of Speed Limits: - Reduced Accident Severity - Improved Driver Reaction Time - Reduced Congestion Impact of Speed Limits on Traffic Safety: - Reduction in Fatalities - Decreased Risk of Injury - Increased Compliance with Traffic Laws

How does an electronic speed controller work ?

An electronic speed controller (ESC) regulates the speed of an electric motor by controlling the electrical power sent to it. It receives a signal, typically a pulse-width modulation (PWM) signal, which it interprets as a desired speed for the motor. The ESC then converts this low-power signal into a high-power electrical current that can drive the motor. By adjusting the duty cycle of the PWM signal, the ESC controls the motor's speed and torque. It also includes features such as overcurrent protection and cooling to ensure reliable operation. Some ESCs even have a feedback loop to monitor the actual speed of the motor and adjust the power output accordingly.

Can speed reading help me save time when studying for exams ?

Speed reading can save time when studying for exams by increasing efficiency, improving recall, managing time better, and reducing stress. However, it may compromise comprehension, not be suitable for all text types, require skill development time, and lead to overconfidence. To effectively use speed reading, start early, combine techniques, take breaks, test comprehension, and customize your approach.

What are some effective speed reading techniques ?

Effective speed reading techniques include pre-reading, chunking, reducing subvocalization, scanning, keyword spotting, pacing, and practice. Pre-reading helps focus on important information, chunking breaks down long sentences into smaller chunks, reducing subvocalization improves reading speed, scanning finds specific information quickly, keyword spotting concentrates on essential details, pacing sets a target reading speed, and practice improves skills over time.

What are some common applications of speed controllers in industries ?

Speed controllers are essential devices used in various industries to regulate the speed of machinery and equipment. They ensure efficient, safe, and precise operation by adjusting speeds according to production requirements, load conditions, and safety standards. Common applications include manufacturing conveyor belts, machine tools, packaging machines, automotive engine testing, chassis dynamometers, textile winders and twisters, food and beverage bottling lines, energy fans and blowers, construction concrete mixers, and crane systems. Overall, speed controllers contribute significantly to the smooth functioning and productivity of these industries.

What is a speed controller and how does it work ?

Speed controllers regulate the speed of electric motors and are used in various applications requiring precise speed control, such as industrial machinery. They consist of an input stage for power supply, a control stage using PID controllers to adjust voltage based on motor speed feedback, and an output stage that converts adjusted voltage for motor use.

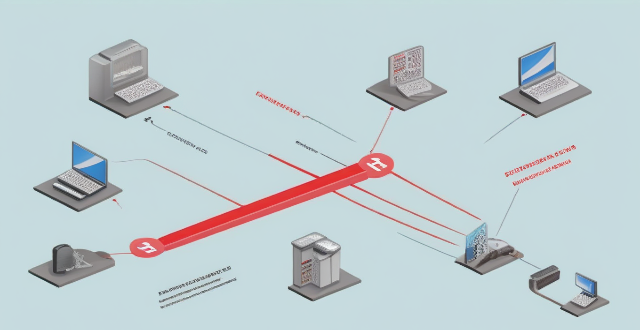

How does network expansion improve internet speed ?

Network expansion enhances internet speeds by reducing congestion, shortening transmission distances, increasing bandwidth, improving redundancy, and allowing for scalability. This process involves adding more nodes to the network, such as routers and switches, which improve data transmission efficiency. By distributing traffic across multiple routes and upgrading infrastructure, internet service providers can meet increasing demand for high-speed connections while maintaining fast and reliable service.

How long does it take to master speed reading ?

Speed reading is a skill that can significantly improve your productivity and efficiency in absorbing information. However, mastering this technique requires time, practice, and dedication. In this article, we will explore the factors that influence the time it takes to master speed reading and provide some tips on how to achieve your goals. Personal learning style, previous reading habits, dedication and practice, and quality of training materials are all factors that influence the time it takes to master speed reading. Tips for mastering speed reading include setting realistic goals, practicing consistently, using visualization techniques, eliminating distractions, and tracking your progress. By understanding these factors and implementing these tips, you can become a proficient speed reader in no time!