Drive Speed

How can I choose the right combination motor drive for my application ?

When selecting a combination motor drive for your application, consider factors such as the type of motor (AC, DC, stepper, or servo), application requirements (load characteristics, speed and torque needs, control precision), appropriate drive technology (VFDs, electronic speed controls, stepper motor drives, servo amplifiers), compatibility and integration with existing systems, performance features (efficiency, dynamic response, protection features), budget and cost considerations (initial and operating costs), and seek professional advice from manufacturers and technical support.

How does a single motor drive compare to a dual motor drive ?

This article compares single motor drives and dual motor drives based on their performance, efficiency, cost, and applications. Single motor drives can only control one motor at a time, while dual motor drives can control two motors simultaneously. Dual motor drives offer higher overall torque and better synchronization between multiple motors, but they also consume more power and require more maintenance. Single motor drives are typically less expensive and well-suited for low power applications with simple movement profiles, while dual motor drives are appropriate for high power applications with complex movement profiles requiring precise synchronization. The choice between a single motor drive and a dual motor drive depends on the specific requirements of the application.

What are the benefits of using a combination motor drive system ?

Combination motor drive systems offer benefits such as improved efficiency, increased reliability, flexibility, and enhanced control. These systems combine the advantages of different types of motors to create a more efficient and reliable drive system. They are ideal for a wide range of applications and can help businesses save money on energy costs while reducing downtime and maintenance requirements.

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

How do hub motors compare to mid-drive motors ?

Electric bicycle motors come in two primary configurations: hub motors and mid-drive motors, each with unique characteristics, advantages, and disadvantages suitable for different riding styles and preferences. Hub motors are integrated directly into the bicycle wheel hub, while mid-drive motors are mounted in the center of the bicycle, near the bottom bracket. Hub motors are generally simpler to install and maintain, quieter, and less expensive than mid-drive motors but are less efficient at higher speeds and can affect bike handling due to changes in wheel diameter and weight distribution. Mid-drive motors offer more efficient power delivery at higher speeds, better weight distribution, and adaptability to various wheel sizes but are generally more complex to install and maintain, louder during operation, and more expensive. Choosing between a hub motor and a mid-drive motor depends on what you value most in an e-bike, such as simplicity, quiet operation, lower cost, efficiency at higher speeds, better weight distribution, or adaptability.

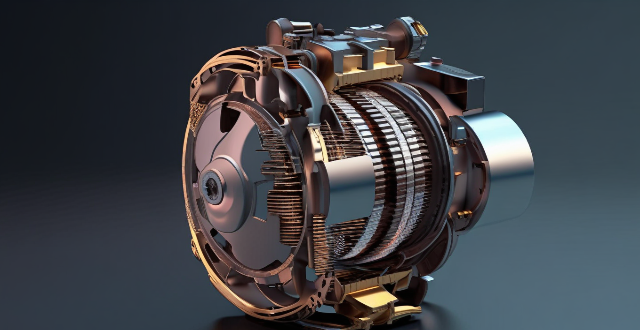

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

What are the advantages of using a drive motor in industrial equipment ?

Drive motors are crucial components in industrial equipment, offering advantages such as increased efficiency, improved accuracy and precision, flexibility and customization, reduced maintenance and downtime, enhanced safety, and environmental benefits. By optimizing processes for maximum productivity and energy savings, drive motors lead to reduced operating costs and increased profitability for businesses. They also provide precise control over machinery movements, allowing for accurate positioning and repeatable operations, which is particularly important in applications where precision is critical. Drive motors offer flexibility in adjusting the speed, direction, and torque of machinery, accommodating changes and meeting specific requirements. Modern drive motors are designed with reliability and durability, minimizing downtime and increasing productivity. They can also be equipped with safety features to prevent accidents and injuries. Finally, drive motors have positive environmental impacts by improving efficiency and reducing energy consumption, leading to reduced greenhouse gas emissions and less waste material produced during manufacturing processes.

What are the key factors to consider when designing a combination motor drive system ?

Designing a combination motor drive system requires careful consideration of several key factors, including load requirements, efficiency and performance, control strategies, reliability and safety, and environmental considerations. Load requirements play a significant role in determining the type and size of the motor required for the drive system, while efficiency and performance are critical factors to consider when designing a motor drive system. Control strategies used in the motor drive system are also crucial, with common strategies including open-loop control, closed-loop control, and adaptive control. Reliability and safety are essential factors to consider when designing a motor drive system, with redundancy, fault detection and protection, and safety interlocks being key considerations. Finally, environmental considerations should also be taken into account when designing a motor drive system, with temperature, humidity, vibration, and shock loads being important factors to consider.

What are the advantages of using a single motor drive system ?

A single motor drive system is a type of electric motor control system that uses only one motor to power a machine or equipment. This system has several advantages over other types of drive systems, including simplified design and maintenance, improved efficiency and performance, increased reliability and longevity, and greater flexibility and versatility. These benefits make it an attractive option for many industrial applications where precise control and efficient operation are essential.

How does an electronic speed controller work ?

An electronic speed controller (ESC) regulates the speed of an electric motor by controlling the electrical power sent to it. It receives a signal, typically a pulse-width modulation (PWM) signal, which it interprets as a desired speed for the motor. The ESC then converts this low-power signal into a high-power electrical current that can drive the motor. By adjusting the duty cycle of the PWM signal, the ESC controls the motor's speed and torque. It also includes features such as overcurrent protection and cooling to ensure reliable operation. Some ESCs even have a feedback loop to monitor the actual speed of the motor and adjust the power output accordingly.

What are the challenges faced when designing a multi-motor drive system ?

The article discusses the challenges of designing a multi-motor drive system, including coordination between motors, power distribution, and synchronization. It emphasizes the importance of control algorithms, communication systems, mechanical design, efficiency optimization, power management, thermal management, timing control, feedback mechanisms, and mechanical design in achieving proper operation of the system. The article concludes that careful consideration of these factors is crucial for creating efficient and effective multi-motor drive systems.

Is it possible to upgrade a machine to a single motor drive ?

The text discusses the possibility of upgrading a machine to a single motor drive. It outlines key considerations such as compatibility, performance requirements, and cost considerations. It also provides steps for upgrading to a single motor drive, including evaluating the machine, selecting a suitable motor drive, modifying the machine, installing the motor drive, and testing and optimizing the machine.

What are the advantages and disadvantages of using a combination motor drive compared to a single motor drive ?

The combination motor drive has several advantages over a single motor drive, including improved performance, enhanced reliability, flexibility in design, energy efficiency, and modularity and scalability. However, it also has disadvantages such as complexity, cost, space requirements, synchronization issues, and integration challenges.

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

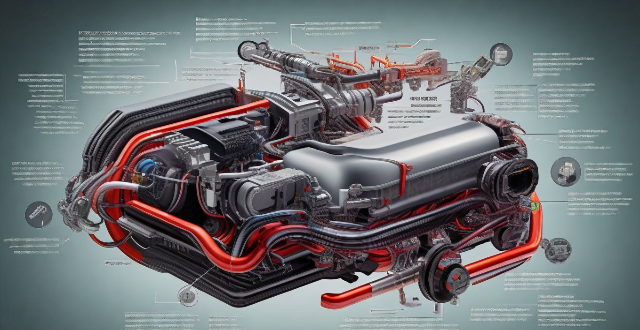

How do I install and maintain a combination motor drive system ?

A combination motor drive system, also known as an integrated drive system or hybrid drivetrain, is a complex assembly of components designed to deliver power from the engine to the wheels of a vehicle. It typically includes an internal combustion engine, one or more electric motors, and a transmission that may incorporate both mechanical and electronic control systems. This guide will walk you through the installation and maintenance process for such a system.

How does speed reading affect comprehension ?

Speed reading is a technique used to read text faster while maintaining or improving comprehension. However, the impact of speed reading on comprehension can vary depending on several factors such as the individual's reading skills, the difficulty level of the material, and the method used for speed reading. In this article, we will explore how speed reading affects comprehension and provide some tips to improve both speed and understanding.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

What is the maximum speed of Wi-Fi 6 ?

Wi-Fi 6, the latest wireless networking standard, offers significant improvements in speed, capacity, and efficiency over its predecessors. The maximum speed of Wi-Fi 6 can reach up to 9.6 Gbps per channel under ideal conditions, thanks to features such as higher data rates, OFDMA, MU-MIMO, BSS Coloring, Target Wake Time, and 1024-QAM. However, real-world performance may vary depending on various factors, and users can expect speeds ranging from several hundred Mbps to a few Gbps in practical scenarios.

What is an electronic speed controller ?

The text provides an overview of electronic speed controllers (ESCs), which are devices used to regulate the power sent to motors in model aircraft and drones. It describes key features such as adjustable throttle, battery protection, signal modulation, and failsafe functionality. The process by which ESCs work is outlined: receiving a signal from the radio transmitter, decoding it into a throttle setting, controlling motor speed based on this setting, and providing feedback to the pilot. Two types of ESCs are mentioned: brushed and brushless, with the latter being more complex and expensive. The text concludes that ESCs are crucial for precise control over motor speed and aircraft performance.

How does a PID (Proportional Integral Derivative) controller differ from other types of speed controllers ?

A PID controller uses three control mechanisms to adjust output based on input error, differing from other speed controllers in flexibility and adaptability.

How do speed limits affect traffic safety ?

Speed limits are crucial components of traffic safety. They serve as a tool to control the speed of vehicles on the road, thereby reducing the risk of accidents and fatalities. In this article, we will discuss how speed limits affect traffic safety in detail. Importance of Speed Limits: - Reduced Accident Severity - Improved Driver Reaction Time - Reduced Congestion Impact of Speed Limits on Traffic Safety: - Reduction in Fatalities - Decreased Risk of Injury - Increased Compliance with Traffic Laws

What is the role of controllers in electric drive motors ?

Controllers play a critical role in electric drive motors, regulating speed, torque, and direction while providing protection against faults. PID, vector control, and FOC controllers are common types used across industries like robotics, automation, transportation, and manufacturing.

**I accidentally deleted some items from my iCloud Drive, can I recover them ?

The article provides a step-by-step guide on how to recover accidentally deleted items from iCloud Drive, emphasizing the importance of acting within a 30-day window for potential recovery. It highlights key actions such as accessing the iCloud website, navigating to iCloud Drive, checking the "Recently Deleted" folder, selecting files for recovery, initiating the recovery process, and verifying the restoration of files. Additionally, it underscores the necessity of having sufficient storage space and maintaining regular backups to prevent future data loss incidents.

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

Can speed reading help me save time when studying for exams ?

Speed reading can save time when studying for exams by increasing efficiency, improving recall, managing time better, and reducing stress. However, it may compromise comprehension, not be suitable for all text types, require skill development time, and lead to overconfidence. To effectively use speed reading, start early, combine techniques, take breaks, test comprehension, and customize your approach.