Hub Speed

How do hub motors compare to mid-drive motors ?

Electric bicycle motors come in two primary configurations: hub motors and mid-drive motors, each with unique characteristics, advantages, and disadvantages suitable for different riding styles and preferences. Hub motors are integrated directly into the bicycle wheel hub, while mid-drive motors are mounted in the center of the bicycle, near the bottom bracket. Hub motors are generally simpler to install and maintain, quieter, and less expensive than mid-drive motors but are less efficient at higher speeds and can affect bike handling due to changes in wheel diameter and weight distribution. Mid-drive motors offer more efficient power delivery at higher speeds, better weight distribution, and adaptability to various wheel sizes but are generally more complex to install and maintain, louder during operation, and more expensive. Choosing between a hub motor and a mid-drive motor depends on what you value most in an e-bike, such as simplicity, quiet operation, lower cost, efficiency at higher speeds, better weight distribution, or adaptability.

Can hub motors be used in bicycles ?

Hub motors, built into the wheel's hub, are compact and lightweight, making them suitable for bicycles. They offer easy installation, quiet operation, and low maintenance but may have limited power output and reduced range. Hub motors are designed for specific wheel sizes and can be more expensive than other electric motors. Despite some disadvantages, they are a popular choice for DIY e-bike projects and those seeking electric power assistance without sacrificing performance or handling characteristics.

How much power can a hub motor generate ?

Hub motors are electric motors built into the wheel's hub and are commonly found in electric vehicles, wheelchairs, and other space-limited applications. The power generation of a hub motor is influenced by its design, size, and the type of battery it uses. Larger motors generally produce more power but require more energy to operate. The control system managing the motor's power output can also affect performance. Examples of hub motor power generation include small electric bikes (250-500 watts), medium electric bikes (500-1000 watts), large electric bikes (over 1000 watts), electric wheelchairs (250-1000 watts), and other applications like golf carts and electric cars with varying power ratings.

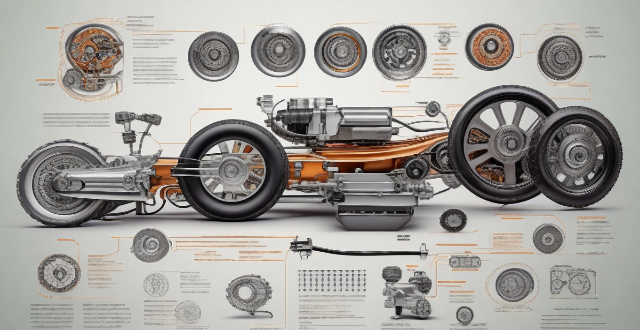

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

How do hub motors affect the handling and performance of a vehicle ?

Hub motors offer numerous benefits for vehicle handling and performance, including improved weight distribution, torque vectoring, and energy recovery through regenerative braking. These features enhance a vehicle's overall efficiency, stability, and performance. As technology advances, we can expect to see more innovative uses for hub motors in the automotive industry.

Are hub motors more expensive than other types of motors ?

Hub motors are generally more expensive than other types of motors, such as brushed DC motors and induction motors. However, they offer several advantages over these motor types, including their compact size, high efficiency, and low maintenance requirements. Brushless DC motors are generally less expensive than hub motors but still offer many of the same benefits. The choice between these motor types will depend on the specific needs and budget of the vehicle manufacturer or end-user.

How long do hub motors typically last ?

Hub motors are crucial for the performance and reliability of electric vehicles. The typical lifespan of hub motors is 50,000 to 100,000 miles or more, depending on various factors such as quality, usage, maintenance, and environmental conditions. Proper maintenance, avoiding overloading, proper storage, using quality accessories, and responsible driving can help extend the lifespan of hub motors.

Are hub motors suitable for off-road vehicles ?

Hub motors, known for their compact design, high efficiency, and low maintenance needs, have become increasingly popular in electric vehicles. However, their suitability for off-road vehicles is a topic of debate due to several challenges. These include waterproofing concerns, potential issues with ground clearance and power output. While hub motors offer advantages such as space-saving design and direct drive power, they must be properly sealed and designed with effective cooling systems to prevent damage from harsh environments. Additionally, the addition of hub motors can reduce ground clearance, making it more difficult for off-road vehicles to navigate rough terrain. In conclusion, whether hub motors are suitable for an off-road vehicle depends on the specific needs and requirements of the application.

What is the role of a network hub in a computer network ?

In this text, the role of a network hub in a computer network is discussed. The main functions of a network hub are data transmission, connectivity, and collision domain management. However, the device also has limitations such as bandwidth sharing, security risks, and scalability issues. Despite its importance in connecting devices and allowing resource sharing, more advanced networking devices are often used in larger and more complex networks to overcome these limitations.

What are the benefits of using hub motors in wheelchairs ?

The article discusses the benefits of using hub motors in wheelchairs, highlighting their improved maneuverability, increased efficiency, quieter operation, simplified design, and enhanced performance. Hub motors are becoming increasingly popular due to these advantages, making them an attractive option for both manufacturers and users. The compact motors offer tighter turning radiuses, longer battery life, reduced energy consumption, less noise during operation, and a more streamlined design. Overall, hub motors provide a comfortable ride and improved handling in various terrains and weather conditions.

How does a hub motor work ?

Hub motors, integral to electric vehicles, operate on electromagnetic principles and Lorentz force. Key components include the stator, rotor, bearings, and controller. When current flows through the stator coils, a magnetic field is generated, which interacts with the rotor's permanent magnets, causing rotation that propels the vehicle. Hub motors are efficient, quiet, and require less maintenance due to their direct drive mechanism and fewer moving parts. However, they can add weight and present cooling challenges. Advancements in technology are expected to enhance their benefits and address limitations.

What are the advantages of using hub motors in electric vehicles ?

Hub motors offer several advantages for electric vehicles, including a simplified design, improved efficiency, enhanced performance, low maintenance requirements, quiet operation, space savings, and environmental benefits.

How do hub motors contribute to energy efficiency in transportation ?

Hub motors contribute to energy efficiency in transportation by offering a direct drive mechanism, regeneration capability, high efficiency at low speeds, weight reduction, and simplified powertrain architecture. These advantages make hub motors an attractive option for electric vehicles and other forms of sustainable transportation seeking to minimize environmental impact while maximizing performance and efficiency.

Are hub motors more efficient than traditional motors ?

Hub motors are generally more efficient than traditional motors due to their direct drive design and lightweight construction. However, traditional motors may still be suitable for certain applications where weight and cooling requirements are not major concerns.

Can hub motors be repaired or replaced easily ?

Hub motors, integral to electric vehicles, can be complex and challenging to repair or replace. Considerations include technical complexity, parts availability, cost implications, and the skill set of technicians. Replacement options depend on manufacturer support, third-party suppliers, DIY possibilities, and vehicle age. Maintenance tips like regular check-ups and software updates can help prolong motor lifespan.

Are there any disadvantages to using hub motors in electric vehicles ?

Hub motors, while offering advantages such as improved efficiency and reduced weight in electric vehicles, also present several potential disadvantages. These include limited torque output requiring higher gearing ratios, thermal management challenges due to difficult heat dissipation leading to potential overheating, increased unsprung weight affecting suspension system performance and vehicle handling, and maintenance and serviceability issues due to difficult accessibility and complex repairs. Manufacturers need to carefully weigh these factors in their EV designs.

Can a speed controller be used to control the speed of an electric motor ?

A speed controller is a device that adjusts the electrical power supplied to an electric motor to change its speed. There are several types of speed controllers available for electric motors, including variable frequency drives (VFDs), DC motor controllers, and phase controllers. Using a speed controller has benefits such as energy efficiency, improved performance, extended motor lifespan, and enhanced safety.

How does speed reading affect comprehension ?

Speed reading is a technique used to read text faster while maintaining or improving comprehension. However, the impact of speed reading on comprehension can vary depending on several factors such as the individual's reading skills, the difficulty level of the material, and the method used for speed reading. In this article, we will explore how speed reading affects comprehension and provide some tips to improve both speed and understanding.

What is the maximum speed of Wi-Fi 6 ?

Wi-Fi 6, the latest wireless networking standard, offers significant improvements in speed, capacity, and efficiency over its predecessors. The maximum speed of Wi-Fi 6 can reach up to 9.6 Gbps per channel under ideal conditions, thanks to features such as higher data rates, OFDMA, MU-MIMO, BSS Coloring, Target Wake Time, and 1024-QAM. However, real-world performance may vary depending on various factors, and users can expect speeds ranging from several hundred Mbps to a few Gbps in practical scenarios.

What is an electronic speed controller ?

The text provides an overview of electronic speed controllers (ESCs), which are devices used to regulate the power sent to motors in model aircraft and drones. It describes key features such as adjustable throttle, battery protection, signal modulation, and failsafe functionality. The process by which ESCs work is outlined: receiving a signal from the radio transmitter, decoding it into a throttle setting, controlling motor speed based on this setting, and providing feedback to the pilot. Two types of ESCs are mentioned: brushed and brushless, with the latter being more complex and expensive. The text concludes that ESCs are crucial for precise control over motor speed and aircraft performance.

How does a PID (Proportional Integral Derivative) controller differ from other types of speed controllers ?

A PID controller uses three control mechanisms to adjust output based on input error, differing from other speed controllers in flexibility and adaptability.

How do speed limits affect traffic safety ?

Speed limits are crucial components of traffic safety. They serve as a tool to control the speed of vehicles on the road, thereby reducing the risk of accidents and fatalities. In this article, we will discuss how speed limits affect traffic safety in detail. Importance of Speed Limits: - Reduced Accident Severity - Improved Driver Reaction Time - Reduced Congestion Impact of Speed Limits on Traffic Safety: - Reduction in Fatalities - Decreased Risk of Injury - Increased Compliance with Traffic Laws

How does an electronic speed controller work ?

An electronic speed controller (ESC) regulates the speed of an electric motor by controlling the electrical power sent to it. It receives a signal, typically a pulse-width modulation (PWM) signal, which it interprets as a desired speed for the motor. The ESC then converts this low-power signal into a high-power electrical current that can drive the motor. By adjusting the duty cycle of the PWM signal, the ESC controls the motor's speed and torque. It also includes features such as overcurrent protection and cooling to ensure reliable operation. Some ESCs even have a feedback loop to monitor the actual speed of the motor and adjust the power output accordingly.

Can speed reading help me save time when studying for exams ?

Speed reading can save time when studying for exams by increasing efficiency, improving recall, managing time better, and reducing stress. However, it may compromise comprehension, not be suitable for all text types, require skill development time, and lead to overconfidence. To effectively use speed reading, start early, combine techniques, take breaks, test comprehension, and customize your approach.

What are some effective speed reading techniques ?

Effective speed reading techniques include pre-reading, chunking, reducing subvocalization, scanning, keyword spotting, pacing, and practice. Pre-reading helps focus on important information, chunking breaks down long sentences into smaller chunks, reducing subvocalization improves reading speed, scanning finds specific information quickly, keyword spotting concentrates on essential details, pacing sets a target reading speed, and practice improves skills over time.

What are some common applications of speed controllers in industries ?

Speed controllers are essential devices used in various industries to regulate the speed of machinery and equipment. They ensure efficient, safe, and precise operation by adjusting speeds according to production requirements, load conditions, and safety standards. Common applications include manufacturing conveyor belts, machine tools, packaging machines, automotive engine testing, chassis dynamometers, textile winders and twisters, food and beverage bottling lines, energy fans and blowers, construction concrete mixers, and crane systems. Overall, speed controllers contribute significantly to the smooth functioning and productivity of these industries.

What is a speed controller and how does it work ?

Speed controllers regulate the speed of electric motors and are used in various applications requiring precise speed control, such as industrial machinery. They consist of an input stage for power supply, a control stage using PID controllers to adjust voltage based on motor speed feedback, and an output stage that converts adjusted voltage for motor use.