Hub Vehicle

How do hub motors affect the handling and performance of a vehicle ?

Hub motors offer numerous benefits for vehicle handling and performance, including improved weight distribution, torque vectoring, and energy recovery through regenerative braking. These features enhance a vehicle's overall efficiency, stability, and performance. As technology advances, we can expect to see more innovative uses for hub motors in the automotive industry.

Are hub motors suitable for off-road vehicles ?

Hub motors, known for their compact design, high efficiency, and low maintenance needs, have become increasingly popular in electric vehicles. However, their suitability for off-road vehicles is a topic of debate due to several challenges. These include waterproofing concerns, potential issues with ground clearance and power output. While hub motors offer advantages such as space-saving design and direct drive power, they must be properly sealed and designed with effective cooling systems to prevent damage from harsh environments. Additionally, the addition of hub motors can reduce ground clearance, making it more difficult for off-road vehicles to navigate rough terrain. In conclusion, whether hub motors are suitable for an off-road vehicle depends on the specific needs and requirements of the application.

What is a hub motor ?

A hub motor is an electric motor integrated into a vehicle's wheel hub, offering direct drive, simplified design, quiet operation, and space efficiency. However, it has limitations such as limited power output, overheating concerns, and cost considerations. Hub motors are commonly used in electric vehicles like bicycles, scooters, motorcycles, and cars.

How long do hub motors typically last ?

Hub motors are crucial for the performance and reliability of electric vehicles. The typical lifespan of hub motors is 50,000 to 100,000 miles or more, depending on various factors such as quality, usage, maintenance, and environmental conditions. Proper maintenance, avoiding overloading, proper storage, using quality accessories, and responsible driving can help extend the lifespan of hub motors.

Can hub motors be repaired or replaced easily ?

Hub motors, integral to electric vehicles, can be complex and challenging to repair or replace. Considerations include technical complexity, parts availability, cost implications, and the skill set of technicians. Replacement options depend on manufacturer support, third-party suppliers, DIY possibilities, and vehicle age. Maintenance tips like regular check-ups and software updates can help prolong motor lifespan.

Are hub motors more expensive than other types of motors ?

Hub motors are generally more expensive than other types of motors, such as brushed DC motors and induction motors. However, they offer several advantages over these motor types, including their compact size, high efficiency, and low maintenance requirements. Brushless DC motors are generally less expensive than hub motors but still offer many of the same benefits. The choice between these motor types will depend on the specific needs and budget of the vehicle manufacturer or end-user.

Are there any disadvantages to using hub motors in electric vehicles ?

Hub motors, while offering advantages such as improved efficiency and reduced weight in electric vehicles, also present several potential disadvantages. These include limited torque output requiring higher gearing ratios, thermal management challenges due to difficult heat dissipation leading to potential overheating, increased unsprung weight affecting suspension system performance and vehicle handling, and maintenance and serviceability issues due to difficult accessibility and complex repairs. Manufacturers need to carefully weigh these factors in their EV designs.

How much power can a hub motor generate ?

Hub motors are electric motors built into the wheel's hub and are commonly found in electric vehicles, wheelchairs, and other space-limited applications. The power generation of a hub motor is influenced by its design, size, and the type of battery it uses. Larger motors generally produce more power but require more energy to operate. The control system managing the motor's power output can also affect performance. Examples of hub motor power generation include small electric bikes (250-500 watts), medium electric bikes (500-1000 watts), large electric bikes (over 1000 watts), electric wheelchairs (250-1000 watts), and other applications like golf carts and electric cars with varying power ratings.

Can hub motors be used in bicycles ?

Hub motors, built into the wheel's hub, are compact and lightweight, making them suitable for bicycles. They offer easy installation, quiet operation, and low maintenance but may have limited power output and reduced range. Hub motors are designed for specific wheel sizes and can be more expensive than other electric motors. Despite some disadvantages, they are a popular choice for DIY e-bike projects and those seeking electric power assistance without sacrificing performance or handling characteristics.

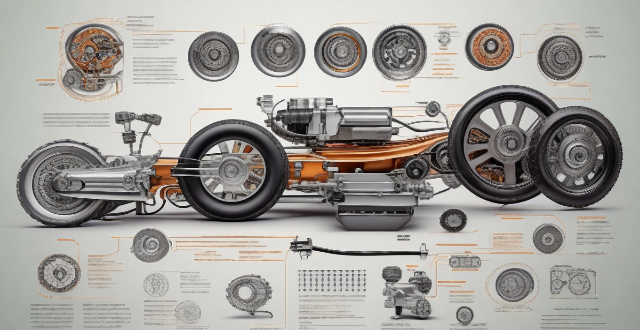

How does a hub motor work ?

Hub motors, integral to electric vehicles, operate on electromagnetic principles and Lorentz force. Key components include the stator, rotor, bearings, and controller. When current flows through the stator coils, a magnetic field is generated, which interacts with the rotor's permanent magnets, causing rotation that propels the vehicle. Hub motors are efficient, quiet, and require less maintenance due to their direct drive mechanism and fewer moving parts. However, they can add weight and present cooling challenges. Advancements in technology are expected to enhance their benefits and address limitations.

What is the role of a network hub in a computer network ?

In this text, the role of a network hub in a computer network is discussed. The main functions of a network hub are data transmission, connectivity, and collision domain management. However, the device also has limitations such as bandwidth sharing, security risks, and scalability issues. Despite its importance in connecting devices and allowing resource sharing, more advanced networking devices are often used in larger and more complex networks to overcome these limitations.

How do hub motors compare to mid-drive motors ?

Electric bicycle motors come in two primary configurations: hub motors and mid-drive motors, each with unique characteristics, advantages, and disadvantages suitable for different riding styles and preferences. Hub motors are integrated directly into the bicycle wheel hub, while mid-drive motors are mounted in the center of the bicycle, near the bottom bracket. Hub motors are generally simpler to install and maintain, quieter, and less expensive than mid-drive motors but are less efficient at higher speeds and can affect bike handling due to changes in wheel diameter and weight distribution. Mid-drive motors offer more efficient power delivery at higher speeds, better weight distribution, and adaptability to various wheel sizes but are generally more complex to install and maintain, louder during operation, and more expensive. Choosing between a hub motor and a mid-drive motor depends on what you value most in an e-bike, such as simplicity, quiet operation, lower cost, efficiency at higher speeds, better weight distribution, or adaptability.

What are the benefits of using hub motors in wheelchairs ?

The article discusses the benefits of using hub motors in wheelchairs, highlighting their improved maneuverability, increased efficiency, quieter operation, simplified design, and enhanced performance. Hub motors are becoming increasingly popular due to these advantages, making them an attractive option for both manufacturers and users. The compact motors offer tighter turning radiuses, longer battery life, reduced energy consumption, less noise during operation, and a more streamlined design. Overall, hub motors provide a comfortable ride and improved handling in various terrains and weather conditions.

How do hub motors contribute to energy efficiency in transportation ?

Hub motors contribute to energy efficiency in transportation by offering a direct drive mechanism, regeneration capability, high efficiency at low speeds, weight reduction, and simplified powertrain architecture. These advantages make hub motors an attractive option for electric vehicles and other forms of sustainable transportation seeking to minimize environmental impact while maximizing performance and efficiency.

What are the advantages of using hub motors in electric vehicles ?

Hub motors offer several advantages for electric vehicles, including a simplified design, improved efficiency, enhanced performance, low maintenance requirements, quiet operation, space savings, and environmental benefits.

How does a Compound Hybrid Electric Vehicle work ?

A compound hybrid electric vehicle (CHEV) is a type of hybrid vehicle that combines the power of an internal combustion engine (ICE) with two or more electric motors, aiming to improve fuel efficiency, reduce emissions, and increase overall performance. The system intelligently manages multiple power sources to provide an efficient, powerful, and environmentally friendly driving experience.

Are there any government incentives for buying an electric vehicle ?

This text discusses the various government incentives available for buying an electric vehicle, including federal tax credits and income tax exemptions, state rebates and grants, sales tax exemptions, high-occupancy vehicle lane access, local parking benefits, and carpool lane access.

How does a Series Hybrid Electric Vehicle compare to a Parallel Hybrid Electric Vehicle ?

Comparison between Series Hybrid Electric Vehicle and Parallel Hybrid Electric Vehicle highlights the differences in power transmission, battery dependency, fuel efficiency, performance, cost, complexity, and regenerative braking capabilities of both types. The series hybrid is more efficient for city driving, while the parallel hybrid suits highway driving better. The choice depends on the user's driving habits and needs, with both offering environmental and economic benefits over traditional vehicles.

Are there any government incentives for purchasing a Series Hybrid Electric Vehicle ?

Government incentives for purchasing a Series Hybrid Electric Vehicle (HEV) vary by country and may include tax credits, rebates, exemptions from fees, charging infrastructure support, and parking benefits. These incentives can help offset the higher initial purchase price of HEVs compared to conventional gasoline vehicles.

Are hub motors more efficient than traditional motors ?

Hub motors are generally more efficient than traditional motors due to their direct drive design and lightweight construction. However, traditional motors may still be suitable for certain applications where weight and cooling requirements are not major concerns.

How does a Series Hybrid Electric Vehicle work ?

A series hybrid electric vehicle (SHEV) is a type of hybrid car that utilizes two power sources: an internal combustion engine (ICE) and an electric motor. The ICE generates electricity to charge the battery pack, which in turn powers the electric motor to propel the vehicle. The main components of a series hybrid electric vehicle include the ICE, battery pack, and electric motor. The working process of a series hybrid electric vehicle involves starting the vehicle with the electric motor drawing power from the battery pack, driving at low speeds or during city driving using only the electric motor, increasing speed or accelerating by starting up the ICE to generate electricity and charge the battery pack, regenerative braking to convert kinetic energy into electrical energy and store it in the battery pack, charging the battery pack when its state of charge falls below a certain level, steady-state driving on highways with the ICE running at its optimal speed while the electric motor provides necessary power, and shutting down both the ICE and electric motor when the vehicle is turned off. Series hybrid electric vehicles offer benefits such as improved fuel efficiency, lower emissions, reduced wear and tear on the ICE, and regenerative braking.

How does a Series Hybrid Electric Vehicle impact the environment ?

Series hybrid electric vehicles (SHEVs) have a positive impact on the environment through reduced emissions and improved fuel efficiency. However, challenges such as battery production and waste management must be addressed to maximize their environmental benefits. The overall impact also depends on factors like the source of electricity for charging and vehicle design efficiency.

How do I install an electronic speed controller in my vehicle ?

An Electronic Speed Controller (ESC) is a device that regulates the speed of an electric motor. It is commonly used in RC cars, drones, and other electronic devices to maintain consistent speed and improve performance. In the context of vehicles, an ESC can be used to control the speed of electric motors in electric or hybrid cars. Installing an ESC in your vehicle involves several steps, which may vary depending on the specific model and make of your vehicle. Here's a general guide to get you started: 1. Choose the right ESC for your vehicle. 2. Disconnect the battery before working on any electrical system in your vehicle. 3. Remove the old controller (if applicable). 4. Mount the ESC in a suitable location within your vehicle. 5. Connect wires and motor according to the manufacturer's instructions. 6. Reconnect the battery and test the system. There are several reasons why you might want to install an ESC in your vehicle, including improved performance, better control, and additional safety features such as overcurrent protection. When installing an ESC, it's important to follow the manufacturer's instructions, wear protective gear, and seek professional assistance if needed.

What is the driving range of a Series Hybrid Electric Vehicle ?

The driving range of a Series Hybrid Electric Vehicle (SHEV) is influenced by factors such as battery pack size, electric motor efficiency, and vehicle weight. Most SHEVs have a combined driving range of around 30-50 miles per gallon equivalent (MPGe), but actual range may vary due to factors like driving conditions and use of accessories. Proper maintenance and consideration of these factors can help maximize the fuel efficiency and environmental benefits of a SHEV.

How does a parallel hybrid electric vehicle (PHEV) work ?

Parallel hybrid electric vehicles (PHEVs) are a type of hybrid vehicle that combines an internal combustion engine (ICE) with an electric motor. The two power sources can work independently or together, depending on the driving conditions. PHEVs have three operating modes: ICE only, electric motor only, and combined power. The energy management system controls the operation of the ICE and electric motor, deciding which power source to use based on driving conditions, battery state of charge, and other factors. PHEVs offer benefits such as improved fuel efficiency, reduced emissions, tax incentives, and reduced dependence on fossil fuels.

How should I prepare my vehicle for a long-distance road trip ?

Preparing Your Vehicle for a Long-Distance Road Trip A long-distance road trip is an exciting adventure, but it's essential to ensure that your vehicle is in top condition before hitting the open road. Here are some steps you can take to prepare your car for the journey ahead: Check the basics such as tires, fluids, lights, and battery. Perform safety checks on brakes, suspension, belts, and hoses. Make sure your entertainment system and charging ports are working correctly. Consider installing seat covers and using organizers or storage solutions to keep items tidy and accessible during the trip. Don't forget to pack an emergency kit with jumper cables, a flashlight, reflective triangles, and a first aid kit just in case you encounter any issues along the way.

Can you drive a parallel hybrid electric vehicle (PHEV) on electricity alone ?

This article discusses the capabilities of parallel hybrid electric vehicles (PHEVs) and their ability to operate solely on electricity. It explains that PHEVs have an electric-only mode that allows them to drive without using the internal combustion engine, but this mode is typically limited to lower speeds and lighter load conditions. The article also highlights the benefits of electric-only driving, such as reduced emissions, quieter operation, and improved fuel efficiency. However, it notes that several factors can affect the electric-only range of a PHEV, including battery size, driving conditions, vehicle load, and tire pressure. Overall, the article emphasizes the importance of understanding your PHEV's capabilities and limitations to maximize its potential for eco-friendly driving.

What is the average fuel consumption of a typical fuel vehicle ?

The average fuel consumption of a typical fuel vehicle can vary depending on several factors such as the type of vehicle, driving conditions, and maintenance. However, we can provide a general overview of the fuel consumption rates for different types of vehicles: - Small cars typically have better fuel efficiency than larger vehicles, with an average fuel consumption of around 6-8 liters per 100 kilometers (L/100km). - Midsize cars usually have slightly higher fuel consumption rates compared to small cars, with an average fuel consumption of around 8-10 L/100km. - Large cars generally have higher fuel consumption rates due to their larger size and weight, with an average fuel consumption of around 10-12 L/100km. - Small SUVs are becoming increasingly popular and offer relatively good fuel efficiency, with an average fuel consumption of around 9-11 L/100km. - Midsize SUVs are larger and heavier than small SUVs, resulting in higher fuel consumption rates, with an average fuel consumption of around 11-13 L/100km. - Large SUVs are the largest and heaviest vehicles in this category, leading to higher fuel consumption rates, with an average fuel consumption of around 13-15 L/100km. - Light duty pickups are designed for carrying light loads and offer reasonable fuel efficiency, with an average fuel consumption of around 12-14 L/100km. - Medium duty pickups are larger and more powerful than light duty pickups, resulting in higher fuel consumption rates, with an average fuel consumption of around 14-16 L/100km. - Heavy duty pickups are designed for heavy-duty tasks and have the highest fuel consumption rates among pickup trucks, with an average fuel consumption of around 16-18 L/100km. It's important to note that these figures are just estimates and actual fuel consumption can vary based on individual driving habits, vehicle condition, and other factors. Additionally, newer vehicles with advanced technology may have lower fuel consumption rates than older models.

How long does a typical power battery last in an electric vehicle ?

Electric vehicles (EVs) have become increasingly popular due to their environmental benefits and lower operating costs. One of the most common concerns for potential EV owners is the lifespan of the vehicle's power battery. In this article, we will explore the typical lifespan of a power battery in an electric vehicle and factors that can affect it. The lifespan of a power battery in an electric vehicle depends on several factors, including the type of battery, driving habits, and maintenance practices. However, a general rule of thumb is that a typical power battery lasts between 8-15 years or 100,000-200,000 miles. Several factors can impact the lifespan of a power battery in an electric vehicle. These include: - Type of Battery: The two most common types of batteries used in EVs are lithium-ion and nickel-metal hydride. Lithium-ion batteries generally have a longer lifespan than nickel-metal hydride batteries. - Driving Habits: Frequent rapid acceleration and braking can shorten the lifespan of a power battery. Additionally, driving at high speeds and in hot temperatures can also negatively impact battery life. - Maintenance Practices: Proper maintenance practices, such as regularly checking and maintaining the cooling system, can help extend the lifespan of a power battery. Neglecting maintenance can lead to premature battery failure. - Charging Habits: Charging the battery to 100% every time can shorten its lifespan. It is recommended to charge the battery to around 80% to prolong its lifespan. As a power battery ages, it may start showing signs of failure. Some common signs include: - Reduced Range: If you notice a significant decrease in the distance your EV can travel on a single charge, it could be a sign that your power battery is failing. - Slow Charging: If your EV takes longer to charge than usual, it could be a sign that your power battery is losing capacity. - Decreased Performance: If you notice a decline in your EV's overall performance, such as slower acceleration or reduced top speed, it could be due to a failing power battery. - Bulging or Swelling: If you notice any physical changes to your power battery, such as bulging or swelling, it is a clear sign that it needs to be replaced. In conclusion, the typical lifespan of a power battery in an electric vehicle is between 8-15 years or 100,000-200,000 miles. However, several factors can impact the lifespan of a power battery, including the type of battery, driving habits, maintenance practices, and charging habits. By being mindful of these factors and properly maintaining your EV's power battery, you can help extend its lifespan and enjoy many years of reliable performance.

What is the maintenance required for a Series Hybrid Electric Vehicle ?

Maintaining a series hybrid electric vehicle (HEV) involves regular checks and replacements similar to conventional gasoline-powered vehicles, along with specific tasks for the electric components. These tasks include tire rotation and air pressure checks, battery state of charge monitoring, brake fluid exchange, oil changes, air filter replacement, spark plug inspection, belt and hose checks, electrical system maintenance such as battery pack health checks, electric motor lubrication, and inverter/converter diagnostics. Additional tips include following manufacturer guidelines, using genuine parts, scheduling regular check-ups, familiarizing with drive modes, avoiding heavy loads, keeping the interior tidy, and carrying an emergency kit.