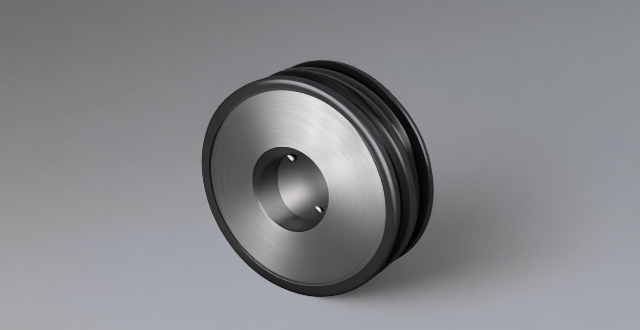

Magnet Design

How does the design of a permanent magnet motor differ from an induction motor ?

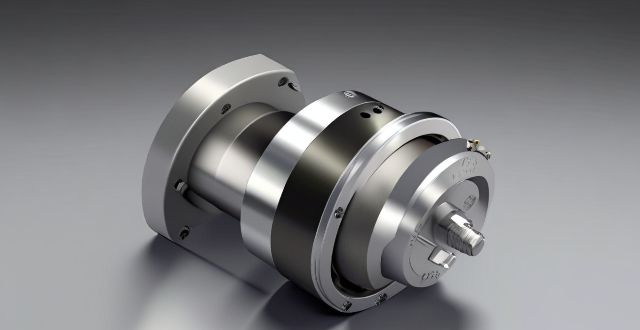

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

Can permanent magnet motors be used in renewable energy systems such as wind turbines ?

Permanent magnet motors are used in renewable energy systems, including wind turbines, due to their high efficiency and reliability. They offer advantages such as high efficiency, low maintenance, good torque characteristics, size and weight benefits, and adaptability. However, challenges and considerations include cost, thermal management, and dependence on rare earth metals. Overall, permanent magnet motors are a popular choice for efficient and reliable energy conversion in wind power applications.

What is the role of neodymium in the production of high-performance permanent magnet motors ?

Neodymium is crucial for making high-performance permanent magnet motors. It increases efficiency, power density, and thermal stability while reducing costs and maintenance. These motors are used in various applications like electric vehicles and aerospace systems.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

Are there any emerging trends or innovations in permanent magnet motor design that could lead to performance improvements ?

Permanent magnet motors (PMMs) have been widely used in various applications due to their high efficiency, power density, and controllability. In recent years, there have been several emerging trends and innovations in PMM design that could lead to performance improvements. These include the use of high-temperature superconducting materials, advanced control strategies, integrated motor and drive systems, and the continued development of REE-free alternatives. As these technologies continue to evolve, we can expect to see even more efficient and powerful PMMs in the future.

In which industries are permanent magnet motors most commonly used ?

Permanent magnet motors are utilized across a wide range of industries due to their efficiency and reliability. Key sectors include the automotive industry, where they power electric and hybrid vehicles and are used in automated manufacturing. In aerospace and defense, PM motors are crucial for aircraft systems and military applications. Appliance manufacturing benefits from PM motors in household and commercial equipment. The medical sector employs them in imaging equipment and surgical tools. Manufacturing and process control use PM motors in CNC machinery and pumps/valves. Renewable energy sectors such as wind turbines and solar tracking systems also rely on these motors. Consumer electronics, including audio and visual equipment as well as toys and hobbyist products, make use of permanent magnet motors for various functions.

How do you maintain and care for a permanent magnet motor to extend its lifespan ?

Permanent magnet motors are widely used in various industries due to their high efficiency, power density, and reliability. However, proper maintenance and care are essential to extend the lifespan of these motors. Here are some tips on how to maintain and care for a permanent magnet motor: - Regular cleaning, lubrication, thermal management, electrical maintenance, mechanical maintenance, environmental considerations, and preventive maintenance schedule are all important aspects of maintaining a permanent magnet motor. - External and internal cleaning should be done regularly to keep the motor clean from dust, dirt, and debris. Lubrication of bearings and gearbox (if any) should be done according to the manufacturer's recommendations. - Thermal management includes ensuring that the cooling system is functioning properly and monitoring the temperature of the motor during operation. Overheating can cause damage to the magnets and other components. - Electrical maintenance involves checking all electrical connections periodically to ensure they are secure and free from corrosion. Insulation resistance should also be tested periodically to detect any potential issues before they become serious problems. - Mechanical maintenance includes ensuring that the motor shaft is properly aligned with the load and performing vibration analysis periodically to identify any mechanical issues such as imbalance or loose parts. - Environmental considerations involve storing and operating the motor in a dry environment to prevent rust and corrosion. Protection from harsh environmental conditions such as extreme temperatures, chemicals, or moisture should also be considered. - A preventive maintenance schedule should be created based on the manufacturer's recommendations and specific application requirements. Regular inspections and prompt attention to any issues will save time and money in the long run by preventing more significant problems from occurring.

Is it possible to recycle the magnets used in permanent magnet motors at the end of their life cycle ?

Permanent magnet motors are widely used in various applications, including electric vehicles, wind turbines, and industrial machinery. However, these motors rely on strong permanent magnets to generate torque and convert electrical energy into mechanical energy. As with any technology, these magnets have a limited lifespan and will eventually need to be replaced or recycled. In this article, we will explore the feasibility of recycling permanent magnets used in motors at the end of their life cycle. One of the main challenges in recycling permanent magnets is that they often contain harmful materials such as neodymium (Nd), dysprosium (Dy), and boron (B). These elements are toxic and require special handling during the recycling process to prevent environmental contamination. Additionally, the extraction and refining processes for these elements can be energy-intensive and costly. Another challenge is the complexity of the recycling process itself. Permanent magnets are typically made up of multiple layers of different materials, including iron, copper, aluminum, and rare earth metals. Separating these materials requires specialized equipment and techniques, which can be expensive and time-consuming. Furthermore, the quality of recycled magnets may not be as high as that of newly manufactured magnets, potentially limiting their usefulness in certain applications. Despite the challenges mentioned above, recycling permanent magnets has several potential benefits. One significant advantage is the conservation of rare earth metals, which are essential components of many modern technologies but are also relatively scarce resources. By recovering these metals from discarded magnets, we can reduce our reliance on new mining operations and help ensure a more sustainable supply chain for critical technologies. Recycling permanent magnets can also lead to cost savings and improved energy efficiency. By reusing materials that would otherwise be discarded, we can reduce waste and lower production costs for new magnets. Additionally, since the recycling process itself requires less energy than extracting and refining raw materials from scratch, it can contribute to overall energy savings and reduced greenhouse gas emissions. There are several methods for recycling permanent magnets, including mechanical separation, chemical extraction, and hydrometallurgical processing. Mechanical separation involves breaking down the magnet into its constituent parts using various tools and machines, such as hammers, grinders, and magnetic separators. Chemical extraction involves dissolving the magnet in acid or other solvents to separate the rare earth metals from other materials. Hydrometallurgical processing involves using water-based solutions to leach out the rare earth metals from the magnet material. While each method has its advantages and disadvantages, all three require specialized equipment and expertise to ensure safe and efficient operations. In conclusion, while there are certainly challenges associated with recycling permanent magnets used in motors at the end of their life cycle, there are also significant potential benefits. By conserving rare earth metals, reducing waste, and improving energy efficiency, we can help create a more sustainable future for critical technologies like permanent magnet motors. With continued research and development in recycling techniques and processes, we can hope to overcome the current challenges and make recycling permanent magnets a viable option for extending their useful lifespan and minimizing environmental impact.

Are permanent magnet motors more susceptible to damage from high temperatures compared to other motor types ?

Permanent magnet motors are more susceptible to high temperatures due to demagnetization and thermal expansion issues, compared to induction motors and switched reluctance motors which primarily face insulation degradation and material fatigue respectively.

How has the development of permanent magnet motor technology evolved over the past decade ?

Over the past decade, permanent magnet motor technology has seen significant advancements due to increased demand for energy-efficient technologies, improvements in materials science, and the growing need for sustainable transportation solutions. Key developments include improved materials like NdFeB and SmCo, advanced manufacturing techniques, innovative designs such as axial flux motors and spoke-type rotor designs, widespread adoption in electric vehicles, and use in energy-efficient applications. Looking ahead, permanent magnet motor technology will continue to evolve and play a vital role in creating more sustainable and energy-efficient systems.

How do permanent magnet motors contribute to energy savings in electric vehicles ?

Permanent magnet motors (PMMs) play a crucial role in enhancing the energy efficiency of electric vehicles (EVs). These motors are designed to convert electrical energy into mechanical energy with minimal losses, making them ideal for use in EVs. In this article, we will discuss the various ways PMMs contribute to energy savings in electric vehicles. One of the primary advantages of PMMs is their high efficiency. They can achieve up to 95% efficiency, which means that only 5% of the input energy is lost during the conversion process. This is significantly higher than other types of motors used in EVs, such as induction motors or DC motors. As a result, PMMs help reduce the amount of energy required to power an EV, leading to increased range and reduced charging times. Another benefit of PMMs is their lightweight design. Compared to traditional motors, PMMs have fewer components and require less material, resulting in a lighter overall weight. This reduction in weight helps improve the vehicle's performance by reducing its total mass and increasing its acceleration and handling capabilities. Additionally, a lighter vehicle requires less energy to move, further contributing to energy savings. PMMs also enable regenerative braking, which is a feature that allows EVs to recover some of the energy typically lost during braking. When the driver applies the brakes, the PMM acts as a generator, converting the kinetic energy of the moving vehicle into electrical energy that can be stored in the battery pack. This recovered energy can then be used to power the vehicle later on, reducing the need for additional charging and increasing the overall efficiency of the EV. Due to their simple design and lack of brushes or commutators, PMMs require less maintenance compared to other types of motors. This reduces the cost of ownership for EV owners and extends the lifespan of the motor, further contributing to energy savings over time. PMMs are capable of operating at a wide range of speeds without sacrificing efficiency. This allows EV manufacturers to design vehicles with optimal gear ratios, reducing the need for multiple gears and transmission systems. By simplifying the drivetrain, PMMs help reduce energy losses associated with complex transmissions and increase the overall efficiency of the vehicle.

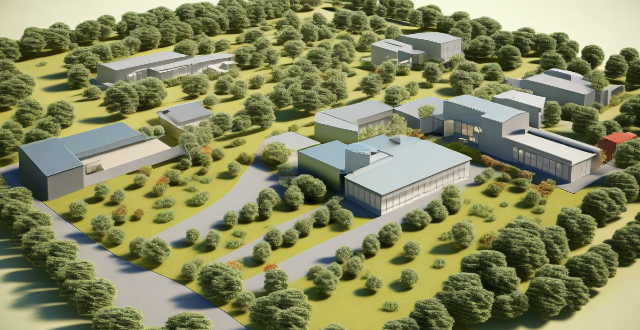

How does ecological design impact energy efficiency in buildings ?

Ecological design significantly impacts energy efficiency in buildings through various strategies like passive solar design, advanced insulation, renewable energy sources, energy-efficient appliances, water conservation, and sustainable material choices. These practices reduce energy consumption, lower operational costs, and minimize environmental harm.

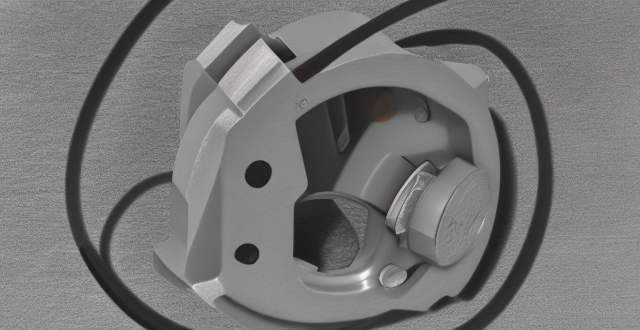

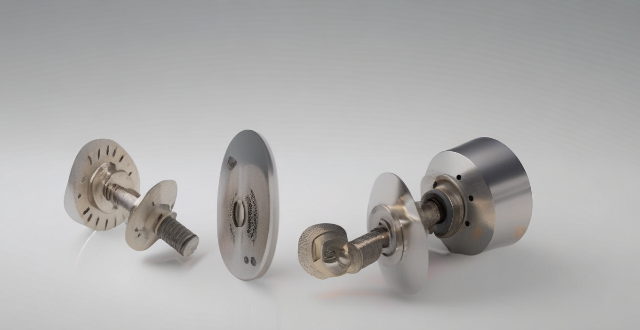

How do permanent magnet motors work, and what makes them more efficient ?

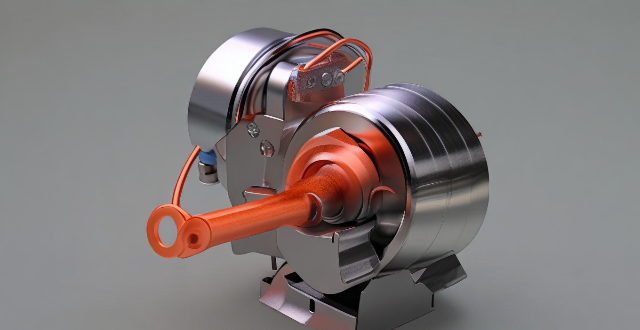

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

Are there any drawbacks to using permanent magnet motors in certain applications ?

The text discusses the drawbacks of using permanent magnet motors in certain applications, including high cost, demagnetization risk, limited speed range, difficulty in controlling torque and speed, and sensitivity to heat and vibration. These factors make them less suitable for applications where cost is a primary concern, precise control is necessary, or exposure to high temperatures or vibrations is common.

What is ecological design, and why is it important ?

Ecological design is a sustainable approach to architecture and engineering that aims to minimize environmental impact. It promotes the use of renewable energy, sustainable materials, and energy-efficient technologies, leading to reduced carbon footprint and conservation of natural resources. Economic benefits include cost savings, increased property value, and job creation. Socially, it fosters healthier living environments, community engagement, and educational opportunities. Ecological design also adapts to climate change by incorporating resilient infrastructure and water management systems. Finally, it promotes innovation through technological advancements, cross-disciplinary collaboration, and research opportunities.

Are there any significant changes to the design of the new MacBook Pro ?

The new MacBook Pro has a slim and lightweight design, larger display, Touch Bar, improved speakers and camera, and more ports.

Is ecological design more expensive than traditional design methods, and is it cost-effective in the long term ?

The article explores the cost implications of ecological design compared to traditional design methods. It acknowledges that ecological design, which emphasizes energy efficiency and sustainability, often comes with higher upfront costs due to factors such as more expensive materials and specialized labor requirements. However, it argues that these initial expenses can be offset by long-term benefits like reduced energy and water bills, lower maintenance costs, improved indoor air quality, and increased property value. The article uses an example of an energy-efficient building to illustrate how the cumulative savings from these benefits can outweigh the initial additional costs over time. In conclusion, while acknowledging the higher upfront costs, the article asserts that ecological design is more cost-effective in the long run and represents a wise investment for both homeowners and developers.

Can you provide examples of successful ecological design projects ?

Ecological design is a concept that focuses on creating structures and spaces that are environmentally friendly, sustainable, and harmonious with their surrounding ecosystems. Here are some examples of successful ecological design projects: 1. The Bullitt Center in Seattle, USA 2. The Green School in Bali, Indonesia 3. The High Line in New York City, USA 4. The Gherkin Building in London, UK 5. The Living Building Challenge in various locations worldwide

What materials are commonly used in ecological design, and why ?

This article discusses materials used in ecological design, including recycled and reclaimed materials such as recycled metals, reclaimed wood, and glass; sustainable materials like bamboo, cork, and linoleum; and low-impact materials such as concrete, insulation, and sheep's wool. It emphasizes that ecological design prioritizes materials with minimal environmental impact throughout their life cycle.

What is the typical cost difference between a permanent magnet motor and an equivalent size induction motor ?

Permanent magnet motors (PMMs) and induction motors (IMs) are two common types of electric motors used in various applications. The cost difference between them is often a significant factor in deciding which one to use. PMMs are known for their high efficiency, compact size, and low noise levels, while IMs are simpler and more robust. The cost difference depends on factors such as size, power rating, materials used, and manufacturing processes. Generally, PMMs are more expensive than IMs of equivalent size due to material costs, manufacturing processes, efficiency and performance requirements, and market demand and availability. When choosing between these two types of motors, it is essential to consider both the technical requirements and budget constraints of your specific application.

What role does technology play in advancing ecological design ?

The text discusses the role of technology in advancing ecological design, which is an approach to architecture and urban planning that emphasizes the integration of natural systems and processes into the built environment. The author outlines various ways in which technology contributes to ecological design, including data collection and analysis, simulation and modeling, sustainable materials and construction methods, energy efficiency and renewable energy sources, water management and conservation, connectivity and automation, and community engagement and education. Overall, technology plays a crucial role in advancing ecological design by providing tools, data, and methods for understanding and enhancing the relationship between human activity and the natural world.

How does ecological design contribute to biodiversity and conservation efforts ?

Ecological design is a crucial approach to enhancing biodiversity and supporting conservation efforts. It integrates principles of ecology and sustainability into the built environment, aiming to minimize negative impacts on natural ecosystems while promoting their health and resilience. Ecological design contributes to these vital efforts by minimizing habitat destruction, promoting ecosystem services, enhancing connectivity, supporting conservation efforts, and implementing best practices. By integrating ecological principles into the built environment, we can create spaces that coexist harmoniously with nature, contributing to a future where both humanity and wildlife thrive.

What are the benefits of applying educational psychology in curriculum design ?

The application of educational psychology principles in curriculum design can significantly improve student learning outcomes, promote their well-being, support teacher effectiveness, address diversity and inclusion, and align with modern educational goals. This approach enhances cognitive development, motivation, adaptive learning strategies, reduces anxiety, increases self-esteem, develops social skills, informs instructional decisions, encourages professional growth, aids classroom management, integrates cultural sensitivity, addresses special education needs, differentiates instruction, prepares students for future challenges, fosters lifelong learning, and effectively uses technology. Overall, this holistic approach to curriculum design benefits both students and educators, preparing learners for success in the 21st century.

What are the main advantages of permanent magnet motors over other types of electric motors ?

Permanent magnet motors (PMMs) have several advantages over other types of electric motors, including high efficiency, low maintenance requirements, high torque density, wide speed range, and quiet operation. These advantages make PMMs ideal for a variety of applications, from small appliances to industrial machinery.

What are the key factors to consider when selecting a permanent magnet motor for a specific application ?

When selecting a permanent magnet motor for a specific application, several key factors must be considered to ensure optimal performance and efficiency. These factors include application requirements, efficiency and performance, size and weight, temperature range and cooling, control and feedback systems, cost and budget, reliability and durability, and compatibility with other system components. By carefully considering these key factors when selecting a permanent magnet motor for your specific application, you can ensure that you choose a motor that meets your needs in terms of performance, efficiency, size, cooling requirements, control options, cost, reliability, and compatibility with other system components.

What are the educational requirements for professionals interested in ecological design ?

Ecological design requires professionals to have a combination of skills and knowledge in various fields. A bachelor's degree is typically required for entry-level positions, with majors such as environmental science, architecture, landscape architecture, and urban planning. Many professionals also pursue a master's degree or certifications to gain specialized knowledge and advance their careers. Certifications include LEED Accredited Professional, Living Building Challenge Certified Professional, American Society of Landscape Architects Certified Professional, and National Council of Interior Design Qualifications Certified Professional Interior Designer.

What are some popular trends in iPhone wallpaper design ?

The text discusses the popular trends in iPhone wallpaper design. The author lists seven different types of designs, including minimalism, nature, abstract art, gradients, retro and nostalgia, pop culture, and personalization. Each type is described briefly with its characteristics and appeal. The first trend is minimalism, which features simple lines and muted colors to create a sense of tranquility. Nature-themed wallpapers are also popular, ranging from landscapes to close-ups of flowers or animals. Abstract art is another trend that adds creativity and individuality to devices. Gradient wallpapers have become increasingly popular, featuring smooth transitions between colors. Retro and nostalgic wallpapers evoke feelings of warmth and familiarity. Pop culture-inspired wallpapers show off interests and personality. Finally, personalized wallpapers feature names, initials, quotes, or other personal touches. In conclusion, there are many popular trends in iPhone wallpaper design. Whether you prefer minimalism, nature, abstract art, gradients, retro styles, pop culture icons, or personalized designs, there is sure to be a trend that suits your taste and style.

What is the relationship between ecological design and green roofs/walls ?

Ecological design emphasizes sustainability and harmony with the environment, incorporating green roofs/walls for energy efficiency, stormwater management, habitat creation, air quality improvement, and aesthetic enhancement. These features require careful consideration of climate, building structure, water management, maintenance, energy efficiency, and habitat connectivity to ensure their success and alignment with ecological design principles.

How does ecological design influence the well-being of building occupants ?

Ecological design, also known as sustainable or green design, is a method of architecture and building that focuses on reducing negative environmental impacts while improving occupant comfort and health. This design philosophy significantly affects the well-being of building occupants in various ways, from enhancing indoor air quality to fostering a connection with nature. Some key aspects through which ecological design enhances occupant well-being include: - Healthier Indoor Environment: Ecologically designed buildings often incorporate advanced ventilation systems that ensure the continuous flow of fresh, filtered air. The use of low VOC (Volatile Organic Compounds) materials reduces pollutants that can cause respiratory issues. Strategic placement of windows allows for ample natural light, reducing the need for artificial lighting and its associated energy consumption. Proper insulation and shading devices maintain comfortable temperatures without overreliance on heating and cooling systems. Orienting buildings to maximize solar gain in colder seasons and minimize it in warmer periods contributes to thermal comfort. - Increased Productivity and Comfort: Eco-friendly soundproofing materials can reduce noise pollution, creating a quieter and more focused work environment. Thoughtful layout planning can minimize noise disturbances and improve speech privacy. The use of window shades and tinting can reduce glare from excessive sunlight, ensuring visual comfort for occupants. Strategically placed reflective surfaces can bounce natural light deeper into spaces, reducing the need for bright artificial lighting. - Mental and Emotional Benefits: Incorporating elements of nature such as plants, water features, and natural materials can reduce stress and increase happiness among occupants. Providing views to the outside world, especially of natural settings, has been shown to boost mood and well-being. Ecological designs often include multi-purpose spaces that can be adapted for various activities, contributing to a sense of variety and adaptability. Designs that blur the line between indoor and outdoor spaces encourage a connection to the outdoors and can enhance mental well-being. - Long-Term Sustainability: Integrating solar panels or wind turbines can make buildings self-sufficient in energy, reducing reliance on non-renewable resources. Using durable, eco-friendly construction materials reduces the need for repairs and replacements, saving costs and reducing waste. Low Maintenance Design: Designing buildings to require minimal maintenance work ensures that they remain healthy, safe, and functional over extended periods.

How have advancements in materials science impacted sports equipment design ?

Advancements in materials science have significantly impacted sports equipment design, improving durability, performance, safety, comfort, and customization. Examples include carbon fiber bats, advanced composite tennis racquets, titanium golf clubs, aerodynamic cycling helmets, shock-absorbing running shoes, breathable athletic apparel, customized orthotics, and personalized mouthguards. These innovations not only enhance the athletes' performance but also reduce waste, making it an environmentally friendly option.