Magnet Energy

Can permanent magnet motors be used in renewable energy systems such as wind turbines ?

Permanent magnet motors are used in renewable energy systems, including wind turbines, due to their high efficiency and reliability. They offer advantages such as high efficiency, low maintenance, good torque characteristics, size and weight benefits, and adaptability. However, challenges and considerations include cost, thermal management, and dependence on rare earth metals. Overall, permanent magnet motors are a popular choice for efficient and reliable energy conversion in wind power applications.

Is it possible to recycle the magnets used in permanent magnet motors at the end of their life cycle ?

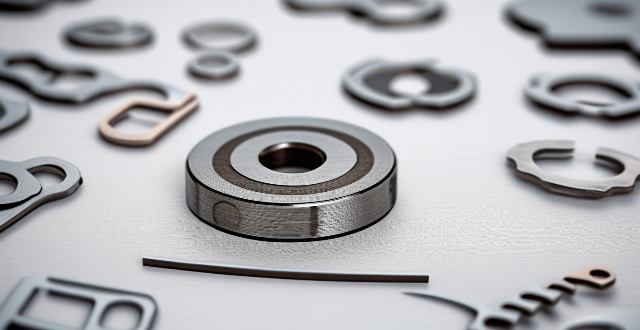

Permanent magnet motors are widely used in various applications, including electric vehicles, wind turbines, and industrial machinery. However, these motors rely on strong permanent magnets to generate torque and convert electrical energy into mechanical energy. As with any technology, these magnets have a limited lifespan and will eventually need to be replaced or recycled. In this article, we will explore the feasibility of recycling permanent magnets used in motors at the end of their life cycle. One of the main challenges in recycling permanent magnets is that they often contain harmful materials such as neodymium (Nd), dysprosium (Dy), and boron (B). These elements are toxic and require special handling during the recycling process to prevent environmental contamination. Additionally, the extraction and refining processes for these elements can be energy-intensive and costly. Another challenge is the complexity of the recycling process itself. Permanent magnets are typically made up of multiple layers of different materials, including iron, copper, aluminum, and rare earth metals. Separating these materials requires specialized equipment and techniques, which can be expensive and time-consuming. Furthermore, the quality of recycled magnets may not be as high as that of newly manufactured magnets, potentially limiting their usefulness in certain applications. Despite the challenges mentioned above, recycling permanent magnets has several potential benefits. One significant advantage is the conservation of rare earth metals, which are essential components of many modern technologies but are also relatively scarce resources. By recovering these metals from discarded magnets, we can reduce our reliance on new mining operations and help ensure a more sustainable supply chain for critical technologies. Recycling permanent magnets can also lead to cost savings and improved energy efficiency. By reusing materials that would otherwise be discarded, we can reduce waste and lower production costs for new magnets. Additionally, since the recycling process itself requires less energy than extracting and refining raw materials from scratch, it can contribute to overall energy savings and reduced greenhouse gas emissions. There are several methods for recycling permanent magnets, including mechanical separation, chemical extraction, and hydrometallurgical processing. Mechanical separation involves breaking down the magnet into its constituent parts using various tools and machines, such as hammers, grinders, and magnetic separators. Chemical extraction involves dissolving the magnet in acid or other solvents to separate the rare earth metals from other materials. Hydrometallurgical processing involves using water-based solutions to leach out the rare earth metals from the magnet material. While each method has its advantages and disadvantages, all three require specialized equipment and expertise to ensure safe and efficient operations. In conclusion, while there are certainly challenges associated with recycling permanent magnets used in motors at the end of their life cycle, there are also significant potential benefits. By conserving rare earth metals, reducing waste, and improving energy efficiency, we can help create a more sustainable future for critical technologies like permanent magnet motors. With continued research and development in recycling techniques and processes, we can hope to overcome the current challenges and make recycling permanent magnets a viable option for extending their useful lifespan and minimizing environmental impact.

What is the role of neodymium in the production of high-performance permanent magnet motors ?

Neodymium is crucial for making high-performance permanent magnet motors. It increases efficiency, power density, and thermal stability while reducing costs and maintenance. These motors are used in various applications like electric vehicles and aerospace systems.

In which industries are permanent magnet motors most commonly used ?

Permanent magnet motors are utilized across a wide range of industries due to their efficiency and reliability. Key sectors include the automotive industry, where they power electric and hybrid vehicles and are used in automated manufacturing. In aerospace and defense, PM motors are crucial for aircraft systems and military applications. Appliance manufacturing benefits from PM motors in household and commercial equipment. The medical sector employs them in imaging equipment and surgical tools. Manufacturing and process control use PM motors in CNC machinery and pumps/valves. Renewable energy sectors such as wind turbines and solar tracking systems also rely on these motors. Consumer electronics, including audio and visual equipment as well as toys and hobbyist products, make use of permanent magnet motors for various functions.

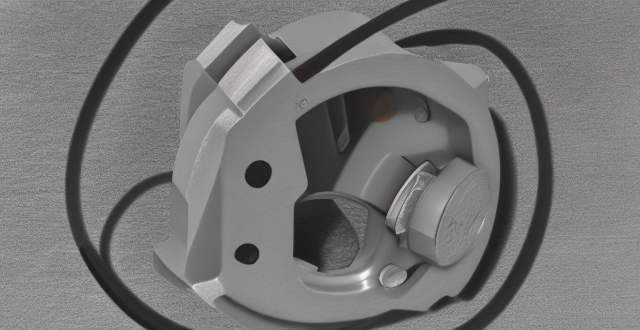

How does the design of a permanent magnet motor differ from an induction motor ?

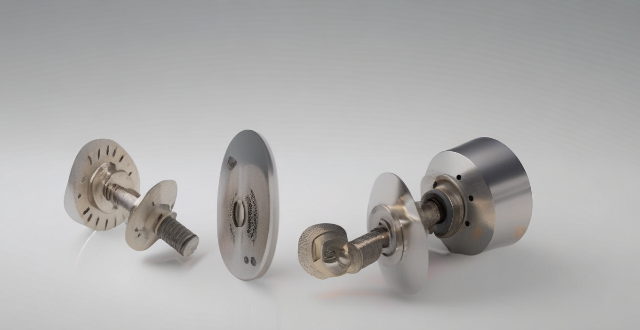

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

How do permanent magnet motors contribute to energy savings in electric vehicles ?

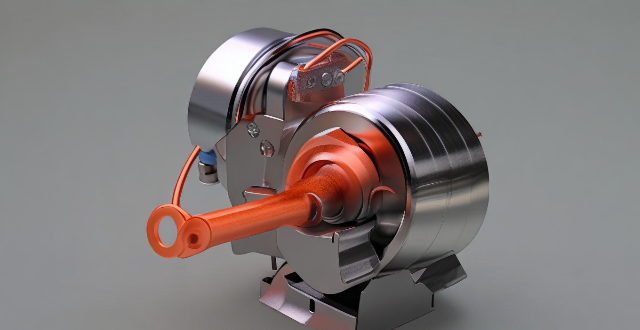

Permanent magnet motors (PMMs) play a crucial role in enhancing the energy efficiency of electric vehicles (EVs). These motors are designed to convert electrical energy into mechanical energy with minimal losses, making them ideal for use in EVs. In this article, we will discuss the various ways PMMs contribute to energy savings in electric vehicles. One of the primary advantages of PMMs is their high efficiency. They can achieve up to 95% efficiency, which means that only 5% of the input energy is lost during the conversion process. This is significantly higher than other types of motors used in EVs, such as induction motors or DC motors. As a result, PMMs help reduce the amount of energy required to power an EV, leading to increased range and reduced charging times. Another benefit of PMMs is their lightweight design. Compared to traditional motors, PMMs have fewer components and require less material, resulting in a lighter overall weight. This reduction in weight helps improve the vehicle's performance by reducing its total mass and increasing its acceleration and handling capabilities. Additionally, a lighter vehicle requires less energy to move, further contributing to energy savings. PMMs also enable regenerative braking, which is a feature that allows EVs to recover some of the energy typically lost during braking. When the driver applies the brakes, the PMM acts as a generator, converting the kinetic energy of the moving vehicle into electrical energy that can be stored in the battery pack. This recovered energy can then be used to power the vehicle later on, reducing the need for additional charging and increasing the overall efficiency of the EV. Due to their simple design and lack of brushes or commutators, PMMs require less maintenance compared to other types of motors. This reduces the cost of ownership for EV owners and extends the lifespan of the motor, further contributing to energy savings over time. PMMs are capable of operating at a wide range of speeds without sacrificing efficiency. This allows EV manufacturers to design vehicles with optimal gear ratios, reducing the need for multiple gears and transmission systems. By simplifying the drivetrain, PMMs help reduce energy losses associated with complex transmissions and increase the overall efficiency of the vehicle.

How do you maintain and care for a permanent magnet motor to extend its lifespan ?

Permanent magnet motors are widely used in various industries due to their high efficiency, power density, and reliability. However, proper maintenance and care are essential to extend the lifespan of these motors. Here are some tips on how to maintain and care for a permanent magnet motor: - Regular cleaning, lubrication, thermal management, electrical maintenance, mechanical maintenance, environmental considerations, and preventive maintenance schedule are all important aspects of maintaining a permanent magnet motor. - External and internal cleaning should be done regularly to keep the motor clean from dust, dirt, and debris. Lubrication of bearings and gearbox (if any) should be done according to the manufacturer's recommendations. - Thermal management includes ensuring that the cooling system is functioning properly and monitoring the temperature of the motor during operation. Overheating can cause damage to the magnets and other components. - Electrical maintenance involves checking all electrical connections periodically to ensure they are secure and free from corrosion. Insulation resistance should also be tested periodically to detect any potential issues before they become serious problems. - Mechanical maintenance includes ensuring that the motor shaft is properly aligned with the load and performing vibration analysis periodically to identify any mechanical issues such as imbalance or loose parts. - Environmental considerations involve storing and operating the motor in a dry environment to prevent rust and corrosion. Protection from harsh environmental conditions such as extreme temperatures, chemicals, or moisture should also be considered. - A preventive maintenance schedule should be created based on the manufacturer's recommendations and specific application requirements. Regular inspections and prompt attention to any issues will save time and money in the long run by preventing more significant problems from occurring.

How do permanent magnet motors work, and what makes them more efficient ?

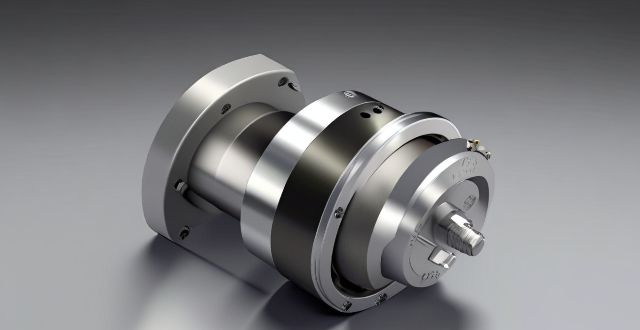

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

How has the development of permanent magnet motor technology evolved over the past decade ?

Over the past decade, permanent magnet motor technology has seen significant advancements due to increased demand for energy-efficient technologies, improvements in materials science, and the growing need for sustainable transportation solutions. Key developments include improved materials like NdFeB and SmCo, advanced manufacturing techniques, innovative designs such as axial flux motors and spoke-type rotor designs, widespread adoption in electric vehicles, and use in energy-efficient applications. Looking ahead, permanent magnet motor technology will continue to evolve and play a vital role in creating more sustainable and energy-efficient systems.

What are the key factors to consider when selecting a permanent magnet motor for a specific application ?

When selecting a permanent magnet motor for a specific application, several key factors must be considered to ensure optimal performance and efficiency. These factors include application requirements, efficiency and performance, size and weight, temperature range and cooling, control and feedback systems, cost and budget, reliability and durability, and compatibility with other system components. By carefully considering these key factors when selecting a permanent magnet motor for your specific application, you can ensure that you choose a motor that meets your needs in terms of performance, efficiency, size, cooling requirements, control options, cost, reliability, and compatibility with other system components.

Are there any drawbacks to using permanent magnet motors in certain applications ?

The text discusses the drawbacks of using permanent magnet motors in certain applications, including high cost, demagnetization risk, limited speed range, difficulty in controlling torque and speed, and sensitivity to heat and vibration. These factors make them less suitable for applications where cost is a primary concern, precise control is necessary, or exposure to high temperatures or vibrations is common.

What are the main advantages of permanent magnet motors over other types of electric motors ?

Permanent magnet motors (PMMs) have several advantages over other types of electric motors, including high efficiency, low maintenance requirements, high torque density, wide speed range, and quiet operation. These advantages make PMMs ideal for a variety of applications, from small appliances to industrial machinery.

Are permanent magnet motors more susceptible to damage from high temperatures compared to other motor types ?

Permanent magnet motors are more susceptible to high temperatures due to demagnetization and thermal expansion issues, compared to induction motors and switched reluctance motors which primarily face insulation degradation and material fatigue respectively.

What is the typical cost difference between a permanent magnet motor and an equivalent size induction motor ?

Permanent magnet motors (PMMs) and induction motors (IMs) are two common types of electric motors used in various applications. The cost difference between them is often a significant factor in deciding which one to use. PMMs are known for their high efficiency, compact size, and low noise levels, while IMs are simpler and more robust. The cost difference depends on factors such as size, power rating, materials used, and manufacturing processes. Generally, PMMs are more expensive than IMs of equivalent size due to material costs, manufacturing processes, efficiency and performance requirements, and market demand and availability. When choosing between these two types of motors, it is essential to consider both the technical requirements and budget constraints of your specific application.

Are there any emerging trends or innovations in permanent magnet motor design that could lead to performance improvements ?

Permanent magnet motors (PMMs) have been widely used in various applications due to their high efficiency, power density, and controllability. In recent years, there have been several emerging trends and innovations in PMM design that could lead to performance improvements. These include the use of high-temperature superconducting materials, advanced control strategies, integrated motor and drive systems, and the continued development of REE-free alternatives. As these technologies continue to evolve, we can expect to see even more efficient and powerful PMMs in the future.

How does clean energy investment compare to traditional energy investment ?

Investing in energy sources is crucial for the development and growth of any economy. However, the choice between clean energy investment and traditional energy investment has become a significant topic of discussion in recent years. This comparison will explore the differences between these two types of investments, focusing on their costs, benefits, and potential impacts on the environment and society.

How do renewable energy sources contribute to industrial energy efficiency improvements ?

Renewable energy sources like solar, wind, hydropower, biomass, and geothermal power play a crucial role in enhancing industrial energy efficiency. They offer benefits such as reduced greenhouse gas emissions, lower operating costs, and increased reliability. By adopting these technologies, businesses can reduce their reliance on fossil fuels, increase energy independence, and contribute to a more sustainable future.

How does an electric car work ?

Electric cars, or EVs, are powered by electricity stored in a battery pack, which is used to power an electric motor that turns the wheels. The process includes starting the car with power from the battery to the controller, which then sends electricity to the motor for acceleration. Braking involves regenerative braking that captures energy to recharge the battery. Charging the battery requires plugging into an external power source managed by an onboard charger. Electric cars boast higher energy efficiency, lower operating costs, reduced environmental impact, quieter operation, and simpler maintenance compared to traditional gasoline vehicles.

What is the future of nuclear energy in the energy market ?

The future of nuclear energy is promising, as it has advantages such as low carbon emissions, high energy density and baseload power. However, challenges like safety concerns, waste disposal, and high costs must be addressed. Increasing demand for clean energy, advances in technology, and integration with renewable sources can drive the growth of nuclear energy in the future.

What is energy transition and why is it important ?

Text: Energy transition is the shift from traditional to renewable energy sources, important for reducing greenhouse gas emissions, promoting sustainable development, and improving energy security. Benefits include economic growth, environmental protection, and social progress.

What is the future outlook for clean energy investment ?

The future outlook for clean energy investment is positive, driven by government policies, technological advancements, and growing demand for sustainable energy sources. However, challenges related to intermittency, infrastructure integration, and competition from fossil fuels need to be addressed to ensure the continued growth of the sector.

Can using energy-efficient appliances help cut down electricity consumption ?

Energy-efficient appliances can help cut down electricity consumption by using less power than traditional counterparts, leading to cost savings and environmental benefits. Examples include LED light bulbs, smart thermostats, and energy star certified refrigerators.

What role do renewable energy sources play in distributed energy systems ?

Renewable energy sources are crucial for distributed energy systems due to their clean, sustainable nature and local generation capabilities. They reduce carbon emissions, enhance energy security, promote local economic development, improve energy efficiency, and enable innovation in these systems.

What impact does climate change legislation have on renewable energy development ?

Climate change legislation significantly influences renewable energy development by providing financial incentives, establishing mandated targets, supporting research and infrastructure, creating consumer awareness, fostering international cooperation, implementing regulations, setting environmental standards, and promoting economic growth through job creation. These measures collectively drive the energy sector towards sustainability and a low-carbon future.

What is the relationship between energy-efficient appliances and overall energy savings ?

The text discusses the connection between energy-efficient appliances and overall energy savings, defining such appliances as those engineered to meet specific efficiency standards. These devices reduce direct energy consumption through lower power requirements and advanced technology, leading to long-term cost benefits and environmental advantages like reduced greenhouse gas emissions. To maximize savings, consumers should research and maintain these appliances properly and replace older models. The relationship underscores the importance of energy-efficient appliances in achieving energy savings for a more sustainable future.

What is the impact of climate change on the energy market ?

Climate change impacts the energy market by increasing demand for cooling, causing unpredictable weather patterns, rising sea levels, and shifting energy sources towards renewables.

What are the main sources of sustainable energy ?

The text discusses the various main sources of sustainable energy, including solar energy, wind energy, hydropower, geothermal energy, bioenergy, tidal and wave energy, and hydrogen energy. It also highlights the importance of adopting sustainable energy for environmental impact, economic benefits, energy security, and health considerations. The transition to sustainable energy requires investment, policy support, and technological innovation.

How is digital technology transforming the energy market ?

Digital technology is revolutionizing the energy market by improving efficiency, enhancing renewable energy sources, facilitating decentralized energy production, enabling smart buildings and homes, and promoting transparency and accountability. This transformation is crucial for meeting the increasing global demand for energy while addressing environmental concerns.

What are the most effective ways to improve energy efficiency in buildings ?

Improving energy efficiency in buildings is essential for environmental and financial reasons. Effective methods include proper insulation, efficient lighting solutions, using energy-efficient appliances, smart controls, harnessing renewable energy sources, and conserving water. These strategies not only reduce operational costs but also create healthier spaces while contributing to sustainability.

What impact do energy storage solutions have on the economics of renewable energy ?

Energy storage solutions significantly impact renewable energy economics by addressing variability and unpredictability. They enhance grid stability, reduce costs, and increase efficiency, thus making renewable energy more viable. With ongoing technological advancements, energy storage will continue to play a crucial role in integrating renewable energy into power grids and achieving global decarbonization goals.