Magnet Winding

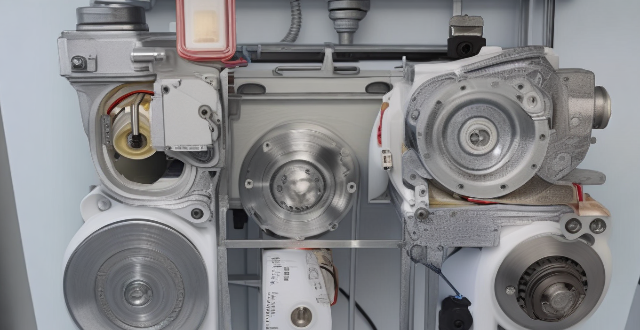

How does the design of a permanent magnet motor differ from an induction motor ?

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

What is the role of neodymium in the production of high-performance permanent magnet motors ?

Neodymium is crucial for making high-performance permanent magnet motors. It increases efficiency, power density, and thermal stability while reducing costs and maintenance. These motors are used in various applications like electric vehicles and aerospace systems.

Can permanent magnet motors be used in renewable energy systems such as wind turbines ?

Permanent magnet motors are used in renewable energy systems, including wind turbines, due to their high efficiency and reliability. They offer advantages such as high efficiency, low maintenance, good torque characteristics, size and weight benefits, and adaptability. However, challenges and considerations include cost, thermal management, and dependence on rare earth metals. Overall, permanent magnet motors are a popular choice for efficient and reliable energy conversion in wind power applications.

In which industries are permanent magnet motors most commonly used ?

Permanent magnet motors are utilized across a wide range of industries due to their efficiency and reliability. Key sectors include the automotive industry, where they power electric and hybrid vehicles and are used in automated manufacturing. In aerospace and defense, PM motors are crucial for aircraft systems and military applications. Appliance manufacturing benefits from PM motors in household and commercial equipment. The medical sector employs them in imaging equipment and surgical tools. Manufacturing and process control use PM motors in CNC machinery and pumps/valves. Renewable energy sectors such as wind turbines and solar tracking systems also rely on these motors. Consumer electronics, including audio and visual equipment as well as toys and hobbyist products, make use of permanent magnet motors for various functions.

How do you maintain and care for a permanent magnet motor to extend its lifespan ?

Permanent magnet motors are widely used in various industries due to their high efficiency, power density, and reliability. However, proper maintenance and care are essential to extend the lifespan of these motors. Here are some tips on how to maintain and care for a permanent magnet motor: - Regular cleaning, lubrication, thermal management, electrical maintenance, mechanical maintenance, environmental considerations, and preventive maintenance schedule are all important aspects of maintaining a permanent magnet motor. - External and internal cleaning should be done regularly to keep the motor clean from dust, dirt, and debris. Lubrication of bearings and gearbox (if any) should be done according to the manufacturer's recommendations. - Thermal management includes ensuring that the cooling system is functioning properly and monitoring the temperature of the motor during operation. Overheating can cause damage to the magnets and other components. - Electrical maintenance involves checking all electrical connections periodically to ensure they are secure and free from corrosion. Insulation resistance should also be tested periodically to detect any potential issues before they become serious problems. - Mechanical maintenance includes ensuring that the motor shaft is properly aligned with the load and performing vibration analysis periodically to identify any mechanical issues such as imbalance or loose parts. - Environmental considerations involve storing and operating the motor in a dry environment to prevent rust and corrosion. Protection from harsh environmental conditions such as extreme temperatures, chemicals, or moisture should also be considered. - A preventive maintenance schedule should be created based on the manufacturer's recommendations and specific application requirements. Regular inspections and prompt attention to any issues will save time and money in the long run by preventing more significant problems from occurring.

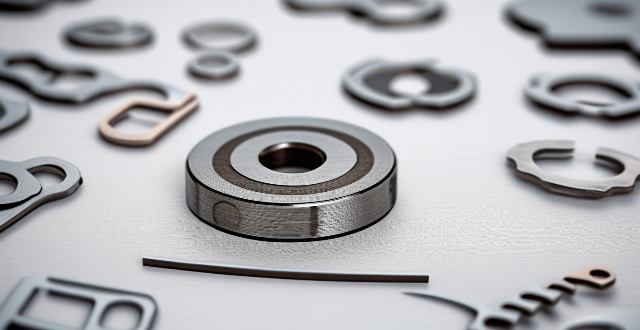

Is it possible to recycle the magnets used in permanent magnet motors at the end of their life cycle ?

Permanent magnet motors are widely used in various applications, including electric vehicles, wind turbines, and industrial machinery. However, these motors rely on strong permanent magnets to generate torque and convert electrical energy into mechanical energy. As with any technology, these magnets have a limited lifespan and will eventually need to be replaced or recycled. In this article, we will explore the feasibility of recycling permanent magnets used in motors at the end of their life cycle. One of the main challenges in recycling permanent magnets is that they often contain harmful materials such as neodymium (Nd), dysprosium (Dy), and boron (B). These elements are toxic and require special handling during the recycling process to prevent environmental contamination. Additionally, the extraction and refining processes for these elements can be energy-intensive and costly. Another challenge is the complexity of the recycling process itself. Permanent magnets are typically made up of multiple layers of different materials, including iron, copper, aluminum, and rare earth metals. Separating these materials requires specialized equipment and techniques, which can be expensive and time-consuming. Furthermore, the quality of recycled magnets may not be as high as that of newly manufactured magnets, potentially limiting their usefulness in certain applications. Despite the challenges mentioned above, recycling permanent magnets has several potential benefits. One significant advantage is the conservation of rare earth metals, which are essential components of many modern technologies but are also relatively scarce resources. By recovering these metals from discarded magnets, we can reduce our reliance on new mining operations and help ensure a more sustainable supply chain for critical technologies. Recycling permanent magnets can also lead to cost savings and improved energy efficiency. By reusing materials that would otherwise be discarded, we can reduce waste and lower production costs for new magnets. Additionally, since the recycling process itself requires less energy than extracting and refining raw materials from scratch, it can contribute to overall energy savings and reduced greenhouse gas emissions. There are several methods for recycling permanent magnets, including mechanical separation, chemical extraction, and hydrometallurgical processing. Mechanical separation involves breaking down the magnet into its constituent parts using various tools and machines, such as hammers, grinders, and magnetic separators. Chemical extraction involves dissolving the magnet in acid or other solvents to separate the rare earth metals from other materials. Hydrometallurgical processing involves using water-based solutions to leach out the rare earth metals from the magnet material. While each method has its advantages and disadvantages, all three require specialized equipment and expertise to ensure safe and efficient operations. In conclusion, while there are certainly challenges associated with recycling permanent magnets used in motors at the end of their life cycle, there are also significant potential benefits. By conserving rare earth metals, reducing waste, and improving energy efficiency, we can help create a more sustainable future for critical technologies like permanent magnet motors. With continued research and development in recycling techniques and processes, we can hope to overcome the current challenges and make recycling permanent magnets a viable option for extending their useful lifespan and minimizing environmental impact.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

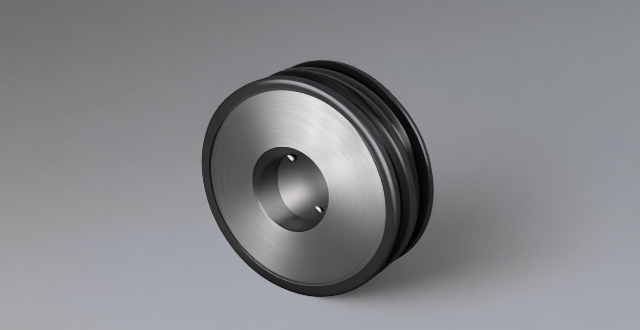

How do permanent magnet motors work, and what makes them more efficient ?

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

Are there any drawbacks to using permanent magnet motors in certain applications ?

The text discusses the drawbacks of using permanent magnet motors in certain applications, including high cost, demagnetization risk, limited speed range, difficulty in controlling torque and speed, and sensitivity to heat and vibration. These factors make them less suitable for applications where cost is a primary concern, precise control is necessary, or exposure to high temperatures or vibrations is common.

How has the development of permanent magnet motor technology evolved over the past decade ?

Over the past decade, permanent magnet motor technology has seen significant advancements due to increased demand for energy-efficient technologies, improvements in materials science, and the growing need for sustainable transportation solutions. Key developments include improved materials like NdFeB and SmCo, advanced manufacturing techniques, innovative designs such as axial flux motors and spoke-type rotor designs, widespread adoption in electric vehicles, and use in energy-efficient applications. Looking ahead, permanent magnet motor technology will continue to evolve and play a vital role in creating more sustainable and energy-efficient systems.

Are permanent magnet motors more susceptible to damage from high temperatures compared to other motor types ?

Permanent magnet motors are more susceptible to high temperatures due to demagnetization and thermal expansion issues, compared to induction motors and switched reluctance motors which primarily face insulation degradation and material fatigue respectively.

What is the typical cost difference between a permanent magnet motor and an equivalent size induction motor ?

Permanent magnet motors (PMMs) and induction motors (IMs) are two common types of electric motors used in various applications. The cost difference between them is often a significant factor in deciding which one to use. PMMs are known for their high efficiency, compact size, and low noise levels, while IMs are simpler and more robust. The cost difference depends on factors such as size, power rating, materials used, and manufacturing processes. Generally, PMMs are more expensive than IMs of equivalent size due to material costs, manufacturing processes, efficiency and performance requirements, and market demand and availability. When choosing between these two types of motors, it is essential to consider both the technical requirements and budget constraints of your specific application.

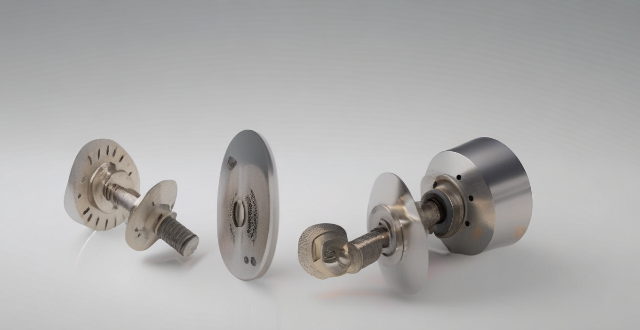

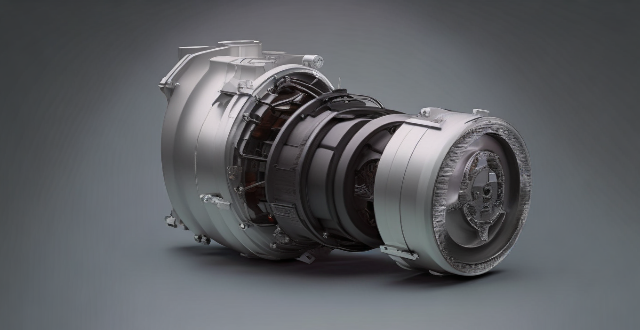

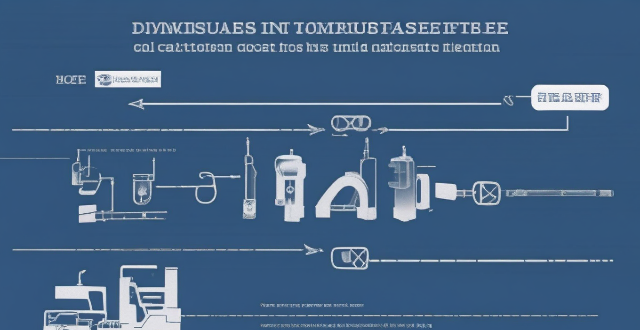

How is an electromagnetic motor designed and constructed ?

Design and construction of an electromagnetic motor involves selecting appropriate components, determining specifications, choosing the type of motor, designing the stator and rotor, calculating winding patterns, assembling the motor, installing a commutator if applicable, connecting wiring and control electronics, testing and troubleshooting, and finalizing and optimizing the design. The key components include the stator, rotor, bearings, commutator, and armature. The steps ensure that the motor meets the required specifications and operates efficiently for its intended use.

What is a brushless motor ?

Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.

What are the main advantages of permanent magnet motors over other types of electric motors ?

Permanent magnet motors (PMMs) have several advantages over other types of electric motors, including high efficiency, low maintenance requirements, high torque density, wide speed range, and quiet operation. These advantages make PMMs ideal for a variety of applications, from small appliances to industrial machinery.

What are the key factors to consider when selecting a permanent magnet motor for a specific application ?

When selecting a permanent magnet motor for a specific application, several key factors must be considered to ensure optimal performance and efficiency. These factors include application requirements, efficiency and performance, size and weight, temperature range and cooling, control and feedback systems, cost and budget, reliability and durability, and compatibility with other system components. By carefully considering these key factors when selecting a permanent magnet motor for your specific application, you can ensure that you choose a motor that meets your needs in terms of performance, efficiency, size, cooling requirements, control options, cost, reliability, and compatibility with other system components.

How do permanent magnet motors contribute to energy savings in electric vehicles ?

Permanent magnet motors (PMMs) play a crucial role in enhancing the energy efficiency of electric vehicles (EVs). These motors are designed to convert electrical energy into mechanical energy with minimal losses, making them ideal for use in EVs. In this article, we will discuss the various ways PMMs contribute to energy savings in electric vehicles. One of the primary advantages of PMMs is their high efficiency. They can achieve up to 95% efficiency, which means that only 5% of the input energy is lost during the conversion process. This is significantly higher than other types of motors used in EVs, such as induction motors or DC motors. As a result, PMMs help reduce the amount of energy required to power an EV, leading to increased range and reduced charging times. Another benefit of PMMs is their lightweight design. Compared to traditional motors, PMMs have fewer components and require less material, resulting in a lighter overall weight. This reduction in weight helps improve the vehicle's performance by reducing its total mass and increasing its acceleration and handling capabilities. Additionally, a lighter vehicle requires less energy to move, further contributing to energy savings. PMMs also enable regenerative braking, which is a feature that allows EVs to recover some of the energy typically lost during braking. When the driver applies the brakes, the PMM acts as a generator, converting the kinetic energy of the moving vehicle into electrical energy that can be stored in the battery pack. This recovered energy can then be used to power the vehicle later on, reducing the need for additional charging and increasing the overall efficiency of the EV. Due to their simple design and lack of brushes or commutators, PMMs require less maintenance compared to other types of motors. This reduces the cost of ownership for EV owners and extends the lifespan of the motor, further contributing to energy savings over time. PMMs are capable of operating at a wide range of speeds without sacrificing efficiency. This allows EV manufacturers to design vehicles with optimal gear ratios, reducing the need for multiple gears and transmission systems. By simplifying the drivetrain, PMMs help reduce energy losses associated with complex transmissions and increase the overall efficiency of the vehicle.

Are there any emerging trends or innovations in permanent magnet motor design that could lead to performance improvements ?

Permanent magnet motors (PMMs) have been widely used in various applications due to their high efficiency, power density, and controllability. In recent years, there have been several emerging trends and innovations in PMM design that could lead to performance improvements. These include the use of high-temperature superconducting materials, advanced control strategies, integrated motor and drive systems, and the continued development of REE-free alternatives. As these technologies continue to evolve, we can expect to see even more efficient and powerful PMMs in the future.

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

What is the best time to exercise for better sleep ?

This article discusses the best time to exercise for better sleep. Regular physical activity is known to improve sleep quality, but the timing of your workout can significantly impact how well you rest at night. The ideal time to exercise is in the morning or early afternoon, as these times allow for ample cooling down and winding down periods before bed. However, individual preferences may vary, and consistency is key; finding a time that works for you and sticking to it will have the most significant impact on your sleep.

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

What are the most scenic routes for a road trip in the US ?

The United States is home to some of the most breathtaking landscapes in the world, making it an ideal destination for a road trip. Here are some of the most scenic routes you can take: 1. Pacific Coast Highway (California) - This iconic drive takes you along the coastline of California, offering stunning views of the ocean and rugged cliffs. Highlights include Big Sur, San Francisco, and Los Angeles. 2. Blue Ridge Parkway (Virginia/North Carolina) - A 469-mile scenic drive that winds through the Appalachian Mountains, taking you through lush forests, rolling hills, and charming small towns. Highlights include Shenandoah National Park, Asheville, and Great Smoky Mountains National Park. 3. Going-to-the-Sun Road (Montana) - A 52-mile scenic drive through Glacier National Park in Montana, taking you through snow-capped mountains, alpine meadows, and crystal-clear lakes. Highlights include Lake McDonald, Logan Pass, and St. Mary Lake. 4. Hana Highway (Hawaii) - A 52-mile winding road that runs along the coastline of Maui in Hawaii, taking you through tropical rainforests, cascading waterfalls, and black sand beaches. Highlights include Wailuku Falls, Hana Town, and Waianapanapa State Park.

What are some creative ways to repurpose second-hand items ?

Repurposing second-hand items is a creative and sustainable practice that can save money and reduce waste. Here are some ideas for giving new life to pre-loved items: furniture makeover, clothing transformations, kitchenware reinvention, accessory revamps, artwork and décor, and kids' toys reimagined. By getting creative with second-hand items, we can contribute to promoting sustainability while saving money.

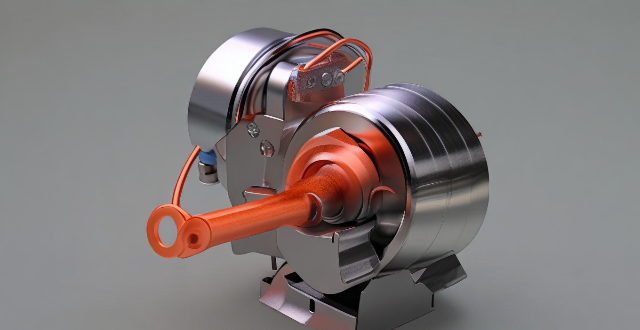

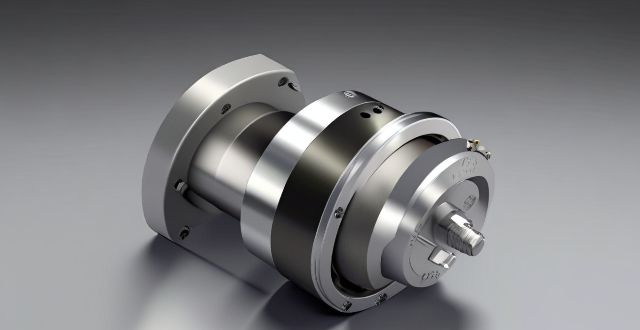

How does a combination motor drive work ?

Combination motor drives integrate VFD and servo controller functionalities to achieve precise speed and torque control for AC induction and permanent magnet synchronous motors. They enhance performance, reduce energy consumption, and extend motor lifespan by offering smooth speed control and reducing wear and tear. Key components include a VFD, servo controller, electric motor, encoder, and user interface. The system uses feedback from an encoder to adjust the motor's input signals, ensuring accurate motion profiles.

How do I choose the right rental car for a road trip ?

When planning a road trip, selecting the right rental car is crucial for comfort, safety, and enjoyment. Here's how to make the best choice: **Consider Your Travel Needs** - Number of Passengers: Determine how many people will be traveling with you. A compact car might suffice for two adults, but a larger group may require an SUV or minivan. - Luggage Space: Think about the amount of luggage you'll have. If you're packing heavily or bringing bulky items like sports equipment, opt for a car with ample trunk space or a hatchback. **Assess the Terrain** - City Driving: If your trip involves mostly city driving, a smaller, fuel-efficient car will be easier to navigate through traffic and park. - Rural or Mountainous Areas: For winding roads and rough terrain, consider a vehicle with better handling and ground clearance, like an SUV or an all-wheel drive vehicle. **Set Your Budget** - Fuel Economy: Check the fuel efficiency ratings of different cars. A more economical car can save you money on gas during your trip. - Rental Rates: Look at the daily or weekly rates for different types of vehicles. Higher-end models and larger vehicles typically cost more to rent. **Check for Features and Add-ons** - GPS and Navigation: Decide if you need in-car navigation. Some rentals come with built-in systems or you might use your smartphone with a mount. - Entertainment: If you'll have children on board, look for rentals that offer rear-seat entertainment systems to keep them occupied. **Safety First** - Safety Ratings: Research the safety ratings of the rental cars you're considering. Choose vehicles with high safety scores to protect you and your passengers. - Emergency Kit: Ensure the rental includes an emergency kit (e.g., spare tire, jack, jumper cables) in case of unforeseen circumstances. **Read Reviews and Ask Questions** - Customer Experience: Read reviews from previous renters to learn about their experiences with specific car models or rental companies. - Insurance Options: Understand the insurance options provided by the rental company and whether it's worth purchasing additional coverage. **Book Early for Best Deals** - Advance Reservations: The earlier you book, the more likely you are to get the car you want at a better rate. - Comparison Shop: Use comparison websites to find the best deals among various rental companies.

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.