Manufacturing Material

Are there any environmental concerns associated with the production and disposal of DC brushed motors ?

The article discusses the environmental concerns associated with DC brushed motors, including high energy consumption, material extraction and processing, manufacturing processes, and end-of-life disposal. It suggests potential solutions such as improved efficiency, sustainable material sourcing and processing, eco-friendly manufacturing practices, and responsible end-of-life management to mitigate their impact on the environment.

How has the adoption of Industry 4.0 technologies influenced energy efficiency in manufacturing ?

Industry 4.0 technologies significantly impact energy efficiency in manufacturing by enabling precision and optimization, data-driven decision making, resource management, promoting sustainability, and enhancing employee engagement. These advancements contribute to a future where smart manufacturing and sustainability are intertwined.

What is the impact of smart manufacturing on industrial energy consumption ?

Smart manufacturing, or Industry 4.0, is transforming industrial operations through AI, IoT, and robotics to boost efficiency and sustainability. One major benefit is its impact on reducing energy consumption in industries. This article discusses how smart manufacturing can aid in decreasing energy usage: 1. **Optimization of Production Processes**: Real-time data analytics and predictive maintenance techniques lead to less energy waste and higher efficiency. Sensors monitor equipment performance to reduce downtime and energy consumption during repairs. 2. **Automation and Robotics**: Replacing manual labor with automated machines and robots results in higher precision and consistency while minimizing energy usage. Smart technologies also enable better resource allocation for reduced energy consumption. 3. **Energy Management Systems (EMS)**: EMS are crucial for monitoring and controlling energy consumption. They provide insights into energy usage patterns, allowing companies to identify areas where energy savings can be achieved. Implementing energy-saving measures based on EMS data can significantly cut energy consumption and costs. 4. **Renewable Energy Sources**: Smart manufacturing promotes the use of renewable energy sources like solar and wind power to reduce dependence on non-renewable sources like fossil fuels. This contributes to environmental sustainability by lowering greenhouse gas emissions. Integrating smart grids into industrial facilities further optimizes energy distribution and enhances efficiency. Overall, smart manufacturing significantly impacts industrial energy consumption by optimizing production processes, incorporating automation and robotics, implementing energy management systems, and promoting renewable energy sources. These advancements not only reduce energy waste but also contribute to environmental sustainability by lowering greenhouse gas emissions.

What is the role of artificial intelligence in modern rocket technology ?

The article discusses the pivotal role of Artificial Intelligence (AI) in revolutionizing various aspects of modern rocket technology. It explores how AI is transforming design and manufacturing processes, including computational fluid dynamics simulations, machine learning-driven material science, and automated manufacturing. The text also delves into AI's contributions to launch and orbital insertion, such as predictive maintenance, trajectory optimization, and real-time decision making. Furthermore, it highlights AI applications in on-orbit operations like autonomous navigation, swarm intelligence, and fault detection and recovery. The article concludes by discussing future implications of AI in deep space exploration, reusable rocketry, and collaborative robotics, emphasizing its potential to make space missions safer, more efficient, and cost-effective.

How does breathable material technology impact sportswear ?

Breathable material technology has revolutionized sportswear by enhancing comfort, performance, durability, and sustainability. This innovation allows for temperature regulation and moisture management, keeping athletes dry and comfortable during physical activity. It also improves muscle efficiency, reduces fatigue, and aids in recovery. Additionally, breathable materials are designed to be durable and long-lasting, reducing the need for frequent replacements. Lastly, eco-friendly production methods and increased durability contribute to environmental benefits by minimizing waste and promoting sustainability.

What are the environmental impacts of electric cars ?

Electric cars, also known as EVs (Electric Vehicles), have become increasingly popular in recent years due to their potential to reduce greenhouse gas emissions and improve air quality. However, like any other technology, electric cars also have some environmental impacts that need to be considered. In this article, we will discuss the various environmental impacts of electric cars. One of the most significant environmental benefits of electric cars is their ability to reduce greenhouse gas emissions. Compared to traditional gasoline-powered vehicles, electric cars produce zero tailpipe emissions. This means that they do not release harmful pollutants such as carbon dioxide, nitrogen oxides, and particulate matter into the atmosphere. As a result, electric cars can help reduce air pollution and improve public health. The environmental impact of electric cars also depends on the source of energy used for charging them. If the electricity used to charge an electric car comes from renewable sources such as wind or solar power, then the overall environmental impact is positive. However, if the electricity comes from coal-fired power plants or other non-renewable sources, then the environmental benefits are reduced. It is essential to ensure that the electricity used for charging electric cars comes from clean and sustainable sources. The production of lithium-ion batteries used in electric cars has some environmental impacts. The mining and processing of raw materials required for battery production can lead to water pollution, soil contamination, and habitat destruction. Additionally, the disposal of spent batteries can pose challenges as they contain toxic chemicals that can harm the environment if not disposed of properly. Recycling programs and research into alternative battery technologies can help mitigate these impacts. The manufacturing process of electric cars also has some environmental impacts. The production of electric car components requires energy and resources, which can lead to greenhouse gas emissions and other forms of pollution. However, compared to traditional gasoline-powered vehicles, electric cars generally have a lower environmental impact during the manufacturing process due to their simpler design and fewer moving parts. To fully understand the environmental impacts of electric cars, it is essential to consider their entire lifecycle, including raw material extraction, manufacturing, use, and disposal. A comprehensive lifecycle analysis can help identify areas where improvements can be made to reduce the overall environmental impact of electric cars. This may include using more sustainable materials, improving energy efficiency during manufacturing, and developing better recycling programs for spent batteries. In conclusion, while electric cars offer significant environmental benefits over traditional gasoline-powered vehicles, they also have some environmental impacts that need to be considered. By addressing these issues through sustainable practices and continued research, we can maximize the positive environmental impacts of electric cars and work towards a cleaner, greener future.

What is the importance of understanding material safety data sheets (MSDS) in chemical handling and protection ?

The text discusses the importance of understanding Material Safety Data Sheets (MSDS) in chemical handling and protection. It explains what an MSDS is, its significance for health and safety, compliance with regulations, environmental protection, and risk management. The article emphasizes that understanding MSDS is crucial for workers and employers to ensure a safe and healthy work environment.

How has automation changed the manufacturing industry ?

Automation has significantly impacted the manufacturing industry by increasing productivity, reducing costs, enhancing safety, and providing flexibility. It has also led to improved data collection and analysis but has shifted labor force needs and raised environmental considerations.

How do safety regulations affect the manufacturing industry ?

Safety regulations are critical in manufacturing for worker safety, environmental protection, and product quality assurance but can increase costs and administrative burden while potentially slowing innovation.

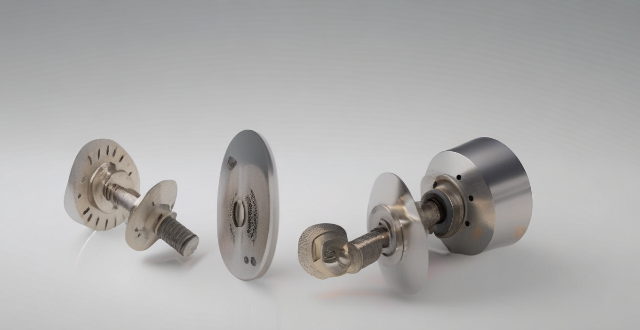

In which industries are permanent magnet motors most commonly used ?

Permanent magnet motors are utilized across a wide range of industries due to their efficiency and reliability. Key sectors include the automotive industry, where they power electric and hybrid vehicles and are used in automated manufacturing. In aerospace and defense, PM motors are crucial for aircraft systems and military applications. Appliance manufacturing benefits from PM motors in household and commercial equipment. The medical sector employs them in imaging equipment and surgical tools. Manufacturing and process control use PM motors in CNC machinery and pumps/valves. Renewable energy sectors such as wind turbines and solar tracking systems also rely on these motors. Consumer electronics, including audio and visual equipment as well as toys and hobbyist products, make use of permanent magnet motors for various functions.

Is it possible to create a truly sustainable "green" battery ?

Creating a truly sustainable "green" battery is an ambitious goal that aligns with the global effort to reduce environmental impact and transition towards renewable energy sources. However, achieving this objective presents significant challenges and requires innovations in materials, design, and production processes. Key considerations for sustainable batteries include eco-friendly raw materials sourcing, recyclability, energy-efficient manufacturing processes, waste management, high energy density, longevity, comprehensive recycling programs, and secondary uses. Challenges and trade-offs involve technological limitations such as research and development needs and potential performance trade-offs, economic implications like increased production costs and market adoption challenges, as well as legislative and regulatory frameworks needed to promote green batteries. In conclusion, creating a truly sustainable "green" battery is feasible but complex, involving multifaceted approaches across material selection, manufacturing processes, product performance, and end-of-life management.

Is green packaging more expensive than traditional packaging ?

Green packaging, designed to reduce environmental impact, is often perceived as more expensive than traditional packaging. The cost difference arises from factors such as material and manufacturing costs, transportation and storage requirements, and marketing expenses. However, elements like increased demand, technological innovations, government policies, and consumer preferences can influence this gap. As these factors evolve, the price difference between green and traditional packaging may decrease over time.

What is the typical cost difference between a permanent magnet motor and an equivalent size induction motor ?

Permanent magnet motors (PMMs) and induction motors (IMs) are two common types of electric motors used in various applications. The cost difference between them is often a significant factor in deciding which one to use. PMMs are known for their high efficiency, compact size, and low noise levels, while IMs are simpler and more robust. The cost difference depends on factors such as size, power rating, materials used, and manufacturing processes. Generally, PMMs are more expensive than IMs of equivalent size due to material costs, manufacturing processes, efficiency and performance requirements, and market demand and availability. When choosing between these two types of motors, it is essential to consider both the technical requirements and budget constraints of your specific application.

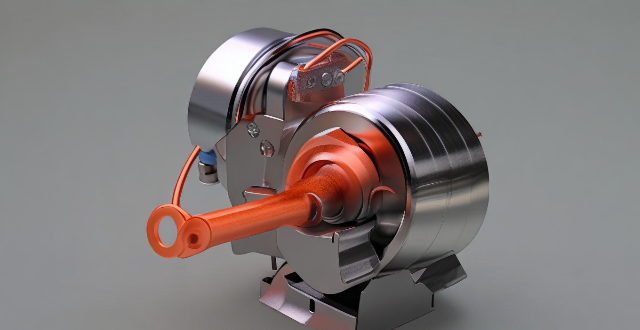

What are the advantages of using a drive motor in industrial equipment ?

Drive motors are crucial components in industrial equipment, offering advantages such as increased efficiency, improved accuracy and precision, flexibility and customization, reduced maintenance and downtime, enhanced safety, and environmental benefits. By optimizing processes for maximum productivity and energy savings, drive motors lead to reduced operating costs and increased profitability for businesses. They also provide precise control over machinery movements, allowing for accurate positioning and repeatable operations, which is particularly important in applications where precision is critical. Drive motors offer flexibility in adjusting the speed, direction, and torque of machinery, accommodating changes and meeting specific requirements. Modern drive motors are designed with reliability and durability, minimizing downtime and increasing productivity. They can also be equipped with safety features to prevent accidents and injuries. Finally, drive motors have positive environmental impacts by improving efficiency and reducing energy consumption, leading to reduced greenhouse gas emissions and less waste material produced during manufacturing processes.

How much will the new product cost ?

This text provides a comprehensive overview of the factors affecting the cost of a new product and outlines a step-by-step process for estimating these costs. It emphasizes the importance of accurate cost estimation for ensuring profitability and competitive pricing in the market. The factors discussed include material, labor, manufacturing overheads, R&D, marketing and sales, administrative expenses, capital expenses, transportation and logistics, taxes and duties, and contingency costs. The cost estimation process involves identifying all cost components, estimating individual costs, calculating total cost, determining pricing strategy, and conducting sensitivity analysis. Overall, this text serves as a valuable guide for businesses looking to estimate the cost of a new product accurately and set a competitive price that ensures profitability.

Can waste reduction lead to cost savings for individuals and companies ?

Waste reduction can lead to cost savings for both individuals and companies by minimizing waste in various aspects of daily life and business operations. For individuals, reducing food waste through meal planning and proper storage, minimizing energy consumption with energy-efficient appliances and water conservation, and reducing unnecessary spending through secondhand shopping and repairing instead of replacing can result in significant cost savings. Companies can also benefit from waste reduction by optimizing production processes with lean manufacturing techniques and resource recovery, improving logistics and supply chain management through just-in-time inventory and efficient packaging, and enhancing energy efficiency with green building design and employee training. Overall, waste reduction is a crucial aspect of sustainable living and business practices that can lead to cost savings while contributing to environmental sustainability.

How does climate-smart technology help in reducing carbon emissions ?

Climate-smart technology plays a crucial role in the global effort to reduce carbon emissions and mitigate the effects of climate change. These technologies are designed to improve energy efficiency, promote renewable energy sources, and optimize industrial processes to minimize their environmental impact. Here's how they contribute to reducing carbon emissions: 1. Energy Efficiency Improvements: Building Automation Systems (Smart Thermostats & Lighting Controls), Transportation Efficiency (Electric Vehicles, Hybrid and Plug-In Hybrid Vehicles). 2. Renewable Energy Sources: Solar Power (Photovoltaic Cells & Solar Water Heaters), Wind Energy (Turbines), Geothermal Energy (Heat Pumps). 3. Industrial Process Optimization: Carbon Capture and Storage (Post-Combustion Capture & Oxy-Fuel Combustion), Process Efficiency (Lean Manufacturing & Industrial Symbiosis). 4. Waste Management and Recycling: Anaerobic Digestion (Organic Waste Treatment), Recycling Technologies (Material Recovery Facilities). 5. Agriculture and Land Use: Precision Farming (GPS-Guided Equipment & No-Till Farming), Forestry Management (Afforestation & Reforestation, Sustainable Forestry Practices). 6. Conclusion: Climate-smart technology offers a diverse array of solutions that, when implemented collectively, can significantly reduce carbon emissions across various sectors of society. By embracing these advancements, we can create a more sustainable future and help combat the escalating challenges of climate change.

What factors do carbon footprint calculators typically consider when calculating emissions ?

Carbon footprint calculators estimate the greenhouse gas emissions from personal lifestyle, organizational activities, and product lifecycles. Key factors include housing energy use, transportation, diet, waste management, operational energy, business travel, supply chain impacts, employee commuting, raw material extraction, manufacturing processes, distribution logistics, product use, and disposal methods. Additional considerations might involve water consumption, land use, and consumer goods production. Accurate estimation requires comprehensive data across these categories to identify emission reduction opportunities and support climate change mitigation efforts.

What is the impact of using climate-friendly products on reducing carbon emissions ?

Using climate-friendly products can significantly reduce carbon emissions by promoting energy efficiency, waste reduction, sustainable material use, support for green initiatives, longer product lifespans, reduced pollution and chemical use, and transportation efficiency. By making conscious choices as consumers, we can collectively contribute to a more sustainable future and help mitigate the effects of climate change.

How has 3D printing technology changed the way we design and produce sports equipment ?

3D printing technology has revolutionized the sports equipment industry by enabling customization, rapid prototyping, complex designs, and on-demand production. This innovation benefits athletes with personalized gear, faster design cycles, optimized performance, and sustainable practices.

What are the benefits of using 3D printing in creating custom sportswear ?

Using 3D printing in creating custom sportswear offers numerous benefits, including improved performance, enhanced support, increased flexibility, personalization and customization, tailored fit, custom designs, sustainability, on-demand production, and reduced waste. This technology allows for intricate patterns and structures that are not possible with traditional manufacturing methods, providing better support, flexibility, and breathability. It also enables the creation of sportswear with personalized designs that reflect individual preferences and requirements. Additionally, using 3D printing promotes sustainability and efficiency by producing only what is needed and reducing waste associated with overproduction. In conclusion, 3D printing is revolutionizing the way we think about sportswear production and consumption, enhancing performance, comfort, style, and promoting sustainability and efficiency.

How has the development of permanent magnet motor technology evolved over the past decade ?

Over the past decade, permanent magnet motor technology has seen significant advancements due to increased demand for energy-efficient technologies, improvements in materials science, and the growing need for sustainable transportation solutions. Key developments include improved materials like NdFeB and SmCo, advanced manufacturing techniques, innovative designs such as axial flux motors and spoke-type rotor designs, widespread adoption in electric vehicles, and use in energy-efficient applications. Looking ahead, permanent magnet motor technology will continue to evolve and play a vital role in creating more sustainable and energy-efficient systems.

How can businesses implement waste reduction practices in their operations ?

This topic discusses the importance of waste reduction in businesses and provides strategies for implementing sustainable practices. It emphasizes the benefits of conducting a waste audit, adopting eco-friendly packaging, optimizing manufacturing processes, promoting reuse and repair, training employees in waste reduction, and partnering with green suppliers. The goal is to contribute to a more sustainable future while also benefiting financially through cost savings and efficiency gains.

What are the most common materials used in the production of protective clothing ?

Protective clothing is designed to safeguard individuals from hazardous environments or conditions. The materials used for such garments play a crucial role in providing the necessary protection while ensuring comfort and functionality. In this article, we will explore the most common materials used in the production of protective clothing: Polyester, Cotton, Nylon, Neoprene, and Gore-Tex.

What are some common applications of speed controllers in industries ?

Speed controllers are essential devices used in various industries to regulate the speed of machinery and equipment. They ensure efficient, safe, and precise operation by adjusting speeds according to production requirements, load conditions, and safety standards. Common applications include manufacturing conveyor belts, machine tools, packaging machines, automotive engine testing, chassis dynamometers, textile winders and twisters, food and beverage bottling lines, energy fans and blowers, construction concrete mixers, and crane systems. Overall, speed controllers contribute significantly to the smooth functioning and productivity of these industries.

What are the challenges in ensuring fair distribution of vaccines ?

The text discusses the challenges in ensuring fair distribution of vaccines, which include production and manufacturing capacity, logistics and supply chain management, allocation and prioritization, political and economic factors, and information and education. These challenges require coordinated efforts at local, national, and international levels to achieve equitable access to vaccines for all people around the world.

How do clean production technologies help reduce waste and pollution ?

Clean production technologies are vital in reducing waste and pollution. They achieve this through energy efficiency, resource efficiency, improved waste management, pollution control, and a holistic approach to sustainability via life cycle assessment. By implementing these technologies, industries can operate in a more sustainable manner, minimizing their environmental impact.

How do industrial processes contribute to greenhouse gas emissions ?

Industrial processes significantly contribute to greenhouse gas (GHG) emissions, which are a major driver of climate change. These contributions come from various sources including energy consumption, manufacturing processes, agricultural industries, construction industries, and waste management. Mitigation strategies such as improving energy efficiency, optimizing processes, implementing carbon capture and storage technologies, and enforcing policy and regulation can help reduce these emissions.

What are some innovative methods for improving industrial energy efficiency ?

Innovative Methods for Improving Industrial Energy Efficiency - Advanced Technologies: AI and Machine Learning for predictive maintenance and optimization of energy consumption, IoT sensor networks and remote control systems. - Process Optimization Techniques: Heat Recovery Systems like energy recuperation and Combined Heat and Power (CHP), process integration through industrial symbiosis and lean manufacturing. - Building Design and Management: Green architecture using eco-friendly materials and natural lighting/ventilation, Smart Building Management Systems with automated controls and energy management software. - Employee Training and Involvement: Educational programs on energy conservation, skill development for new technologies, participation incentives through reward systems and team challenges.