Ping Stator

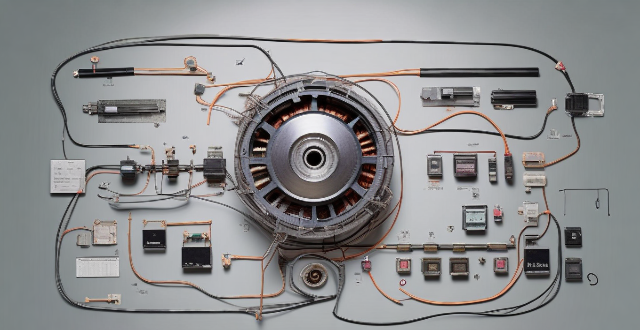

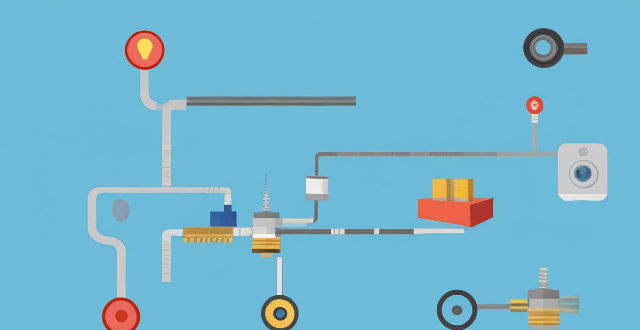

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

What is a DC brushed motor and how does it work ?

**DC Brushed Motor Overview:** A DC brushed motor is an electric machine that converts direct current into mechanical energy, utilizing magnetic fields and electromagnetism. It consists of a stator, rotor, brushes, and a commutator. The motor operates by applying DC voltage to the stator windings, creating a magnetic field that interacts with the rotor's magnets, initiating rotation. Brushes and the commutator ensure continuous motion in one direction. Speed control is achieved by varying the voltage or stator's magnetic field strength. While these motors offer advantages like easy speed control and high starting torque, they require maintenance due to brush wear and can cause sparking.

What is a brushless motor ?

Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.

In what ways does sports culture influence political discourse and international relations ?

The text discusses how sports culture significantly impacts political discourse and international relations. It highlights various ways this influence manifests, including promoting diplomacy and peace, fueling nationalism and identity, driving economic development, advocating for social issues, and shaping public opinion through media representation. The article also mentions specific examples such as "Ping-Pong Diplomacy," Olympic Truce, and the involvement of sports figures in peace agreements. It underscores the role of sports in cultural exchange, global marketplace activities, brand promotion, and environmental concerns. Additionally, it touches upon the use of sports for propaganda purposes, controversies like doping scandals, and their effects on international perceptions. Overall, the text emphasizes that sports culture is a potent force intertwined with global dynamics, reflecting and shaping interactions between nations.

Is there a way to measure network latency ?

Measuring network latency is crucial for understanding a network's performance. The ping test, traceroute, and online tools are methods to measure latency. Ping tests estimate the round-trip time, while traceroute identifies bottlenecks in the network path. Online tools provide visual representations of network performance.

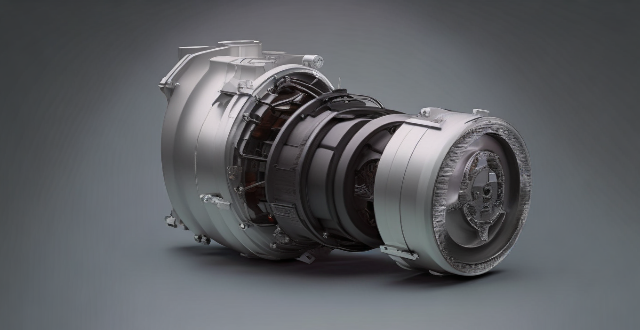

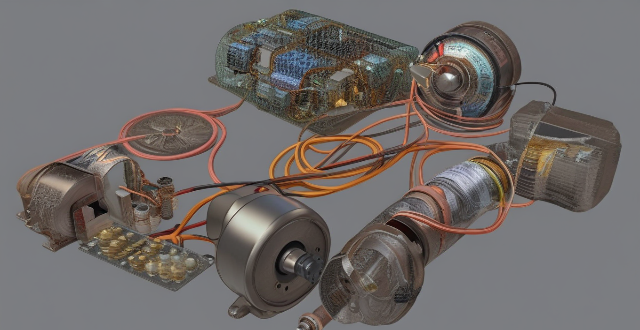

How does an electromagnetic motor work ?

The article provides a comprehensive overview of how an electromagnetic motor works, including its basic components such as the stator, rotor, bearings, commutator (in DC motors), and armature (in AC motors). It explains the operating principles in four steps: applying electrical energy to create a magnetic field around the stator coils, the interaction between the magnetic fields of the stator and rotor causing the Lorentz force, the rotation of the rotor as it tries to align its magnetic poles with those of the stator, and maintaining consistent rotation through current reversal by the commutator in DC motors or changing polarity in AC motors. The article also discusses different types of electromagnetic motors like DC motors, AC motors, stepper motors, synchronous motors, and induction motors, highlighting their unique characteristics and suitability for various applications based on efficiency, power requirements, and control complexity.

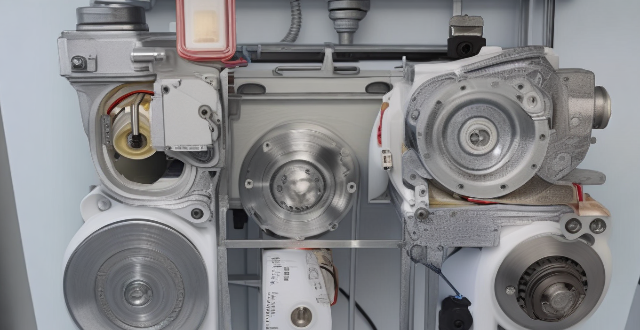

How does an internal rotor motor work ?

Internal rotor motors operate through the interaction of magnetic fields produced by their stator and rotor components, generating rotational force and torque. They offer advantages such as high efficiency and precise speed control but also have drawbacks like increased complexity and maintenance requirements.

How does the design of a permanent magnet motor differ from an induction motor ?

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

Are there any tools to help diagnose network latency issues ?

Network latency issues can be frustrating and detrimental to the performance of applications and services. Fortunately, there are several tools available that can help diagnose and troubleshoot these issues. Some popular tools used for network latency diagnosis include Ping, Traceroute, MTR (My Traceroute), Netstat, Tcpdump, and Wireshark. Each tool has its own strengths and weaknesses, so it's important to choose the right one based on your specific needs and circumstances. By using these tools effectively, you can identify and resolve latency problems quickly and efficiently.

Have there been any instances where sporting events have led to improved diplomatic relations ?

Sporting events have been used to improve diplomatic relations between countries, bringing people together regardless of their backgrounds or beliefs. Examples include Ping-Pong diplomacy in the 1970s between China and the US, soccer matches promoting peace in the Middle East, the Olympic Truce symbolizing goodwill and cooperation, and rugby matches representing reconciliation and forgiveness.

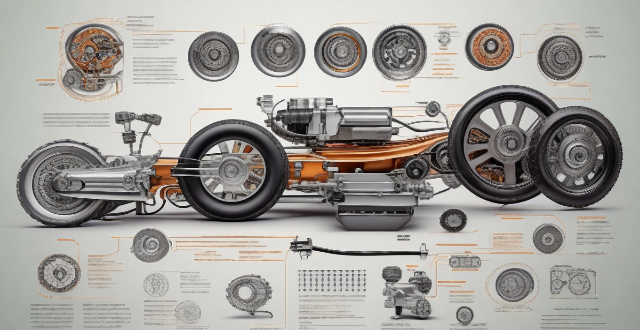

Can you explain the differences between an internal and external rotor motor ?

Motors are crucial components of various mechanical systems, and understanding their types is essential for selecting the appropriate one for a specific application. Two common types of motors are internal rotor motors and external rotor motors. An internal rotor motor has its rotor located inside the stator, while an external rotor motor has its rotor located outside the stator. The main differences between these two types of motors include rotor location, torque output, cooling efficiency, maintenance accessibility, and application suitability. Understanding these differences can help in selecting the appropriate motor type for a given task.

How do you control the speed and torque of an AC stepping motor ?

The text provides a comprehensive overview of controlling the speed and torque of an AC stepping motor, emphasizing the importance of understanding its basic principles and utilizing appropriate control techniques. Key points include the motor's working principle, torque generation, and step resolution, as well as various control methods such as pulse rate modulation, microstepping, closed-loop control, current limiting, voltage control, and soft start/stop. Practical considerations like drive system compatibility, thermal management, load factors, and safety precautions are also highlighted for optimal motor performance and longevity.

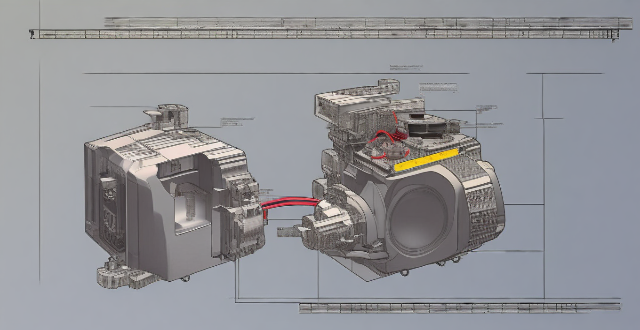

How is an electromagnetic motor designed and constructed ?

Design and construction of an electromagnetic motor involves selecting appropriate components, determining specifications, choosing the type of motor, designing the stator and rotor, calculating winding patterns, assembling the motor, installing a commutator if applicable, connecting wiring and control electronics, testing and troubleshooting, and finalizing and optimizing the design. The key components include the stator, rotor, bearings, commutator, and armature. The steps ensure that the motor meets the required specifications and operates efficiently for its intended use.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

How do permanent magnet motors work, and what makes them more efficient ?

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

In what applications are internal rotor motors commonly used ?

Internal rotor motors, also known as rotary motors or simply electric motors, are widely used in various applications due to their ability to convert electrical energy into mechanical energy. These motors consist of a stationary component (stator) and a rotating component (rotor), which is located inside the stator. The rotor is driven by electromagnetic forces generated by the interaction between the stator and rotor windings. In conclusion, internal rotor motors play a crucial role across numerous sectors, from industrial manufacturing to domestic appliances and even critical medical equipment. Their versatility makes them an essential component in modern technology advancements.

How does a hub motor work ?

Hub motors, integral to electric vehicles, operate on electromagnetic principles and Lorentz force. Key components include the stator, rotor, bearings, and controller. When current flows through the stator coils, a magnetic field is generated, which interacts with the rotor's permanent magnets, causing rotation that propels the vehicle. Hub motors are efficient, quiet, and require less maintenance due to their direct drive mechanism and fewer moving parts. However, they can add weight and present cooling challenges. Advancements in technology are expected to enhance their benefits and address limitations.

What is considered high network latency ?

High network latency is a delay in data transmission that can negatively affect the performance of applications and services. It is influenced by various factors such as distance, congestion, hardware performance, bandwidth limitations, QoS settings, and interference. The definition of high latency varies depending on the context, but it is generally considered to be any delay that significantly impacts the usability of applications or services. Identifying high network latency can be done using tools like ping tests or traceroute commands. Mitigating high network latency can involve upgrading hardware, increasing bandwidth, optimizing QoS settings, reducing physical distance, and minimizing interference.

Where can I enjoy haute cuisine in Hong Kong without breaking the bank ?

Hong Kong is a food lover's paradise, offering a wide range of culinary delights at various price points. Here are some budget-friendly options for enjoying haute cuisine in the city: 1. **Tim Ho Wan** - The World's Cheapest Michelin-starred Restaurant offers dim sum dishes like Baked Buns with BBQ Pork for HK$20-50 per dish. 2. **Yung Kee Restaurant** - Affordable Roast Goose is renowned for its crispy and juicy roast goose, with meals costing HK$100-200. 3. **Tai Ping Koon** - Budget-Friendly Seafood Restaurant serves fresh seafood dishes like steamed fish and shrimp with garlic for HK$50-100 per dish. 4. **Lan Fong Yuen** - No-frills Tea House with Reasonable Prices offers traditional Cantonese tea and snacks since 1956, with prices ranging from HK$20-40 per person. 5. **Kau Kee Restaurant** - Affordable Noodles and Congee is known for its beef brisket noodles and congee, with meals costing HK$30-50. 6. **Lin Heung Kuttay** - Cheap and Cheerful Desserts specializes in traditional Chinese desserts like mango pomelo sago soup and durian pudding, with prices ranging from HK$10-30 per dessert. These options prove that you don't have to spend a fortune to enjoy delicious food in Hong Kong.

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

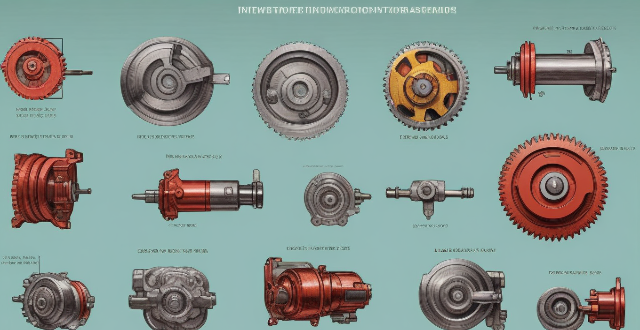

What is an electromagnetic motor ?

Electromagnetic motors are electric motors that use electromagnetic force to convert electrical energy into mechanical energy. They consist of a stator (stationary part) and a rotor (rotating part), along with components like a commutator, brushes, and an armature. The operation involves generating magnetic fields, current flow in rotor coils, interaction between these fields, continuous rotation facilitated by the commutator, and mechanical output through the shaft. Types include DC motors, AC motors, stepper motors, and universal motors, each suitable for different applications.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

Can you explain the concept of vector control in multi-motor drives ?

Vector control is a method for controlling the speed and torque of electric motors, especially AC motors, in multi-motor drives. It works by decoupling the flux-producing and torque-producing components of the stator current, allowing for independent control of both. This results in improved dynamic response, precise speed regulation, energy efficiency, reduced mechanical stress, and adaptability to different motor types.

What are the different types of electromagnetic motors ?

This article discusses the various types of electromagnetic motors, including DC motors (brushed and brushless), AC motors (induction and synchronous), stepper motors (bipolar and unipolar), and servo motors (DC and AC). Each type of motor has unique features and applications, such as power demand, speed range, accuracy, and cost. The choice of motor depends on the specific requirements of the application.

Is it possible for sports to transcend political differences and bring nations together ?

The article discusses the potential of sports to transcend political differences and bring nations together. It highlights three key ways in which sports can achieve this: through competition, cultural exchange, and diplomacy. The power of sports is demonstrated through various examples, such as the Olympics, World Cup, NBA, Formula One, Ping-Pong Diplomacy, and Peace Games. The article concludes that while political conflicts may still exist outside of sports, these activities provide a platform for positive interactions and collaboration that can lead to lasting change.

What are the advantages of using an internal rotor motor ?

An internal rotor motor is a type of electric motor where the rotor is located inside the stator. This design has several advantages over other types of motors, such as external rotor motors or brushed motors. Some of these advantages include higher efficiency, improved heat dissipation, lower noise levels, better control and response, compact design, and reduced maintenance costs. These benefits make internal rotor motors a popular choice for various applications across industries.