Ping Torque

How do you control the speed and torque of an AC stepping motor ?

The text provides a comprehensive overview of controlling the speed and torque of an AC stepping motor, emphasizing the importance of understanding its basic principles and utilizing appropriate control techniques. Key points include the motor's working principle, torque generation, and step resolution, as well as various control methods such as pulse rate modulation, microstepping, closed-loop control, current limiting, voltage control, and soft start/stop. Practical considerations like drive system compatibility, thermal management, load factors, and safety precautions are also highlighted for optimal motor performance and longevity.

Can you explain the concept of vector control in multi-motor drives ?

Vector control is a method for controlling the speed and torque of electric motors, especially AC motors, in multi-motor drives. It works by decoupling the flux-producing and torque-producing components of the stator current, allowing for independent control of both. This results in improved dynamic response, precise speed regulation, energy efficiency, reduced mechanical stress, and adaptability to different motor types.

How do you troubleshoot common issues with AC stepping motors, such as missing steps or low torque ?

Troubleshooting common issues with AC stepping motors involves addressing problems such as missing steps or low torque. This is done by checking the power supply, examining the drive system, analyzing mechanical components, evaluating control signals, and considering environmental factors. It is important to approach the problem methodically, starting with basic checks before moving on to more complex diagnostics.

In what ways does sports culture influence political discourse and international relations ?

The text discusses how sports culture significantly impacts political discourse and international relations. It highlights various ways this influence manifests, including promoting diplomacy and peace, fueling nationalism and identity, driving economic development, advocating for social issues, and shaping public opinion through media representation. The article also mentions specific examples such as "Ping-Pong Diplomacy," Olympic Truce, and the involvement of sports figures in peace agreements. It underscores the role of sports in cultural exchange, global marketplace activities, brand promotion, and environmental concerns. Additionally, it touches upon the use of sports for propaganda purposes, controversies like doping scandals, and their effects on international perceptions. Overall, the text emphasizes that sports culture is a potent force intertwined with global dynamics, reflecting and shaping interactions between nations.

What are the advantages of using an AC stepping motor compared to a DC stepping motor ?

The text discusses the advantages of using AC stepping motors compared to DC stepping motors. The main points include: 1. **Simplified Drive Circuitry**: AC stepping motors have simpler drive circuitry than DC stepping motors, leading to fewer components and a more streamlined design, which reduces complexity and lowers manufacturing costs. 2. **Higher Torque Output**: AC stepping motors typically offer higher torque output than DC stepping motors, making them ideal for applications requiring high torque at low speeds. This also leads to improved efficiency and reduced energy consumption. 3. **Better Heat Dissipation**: AC stepping motors often have better heat dissipation capabilities due to their larger surface area and improved cooling mechanisms, allowing them to operate at higher temperatures without overheating and extending their lifespan. 4. **Compatibility with Standard AC Power Sources**: AC stepping motors are compatible with standard AC power sources widely available in industrial and commercial settings, eliminating the need for additional power supplies or conversion equipment and simplifying installation. 5. **Lower Maintenance Requirements**: AC stepping motors generally require less maintenance than DC stepping motors, as they have fewer moving parts and simpler drive circuitry, reducing maintenance costs and downtime. Overall, the text highlights that AC stepping motors offer significant benefits over DC stepping motors in terms of simplicity, performance, efficiency, compatibility, and maintenance, making them a popular choice for various applications where precision control and reliability are essential.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

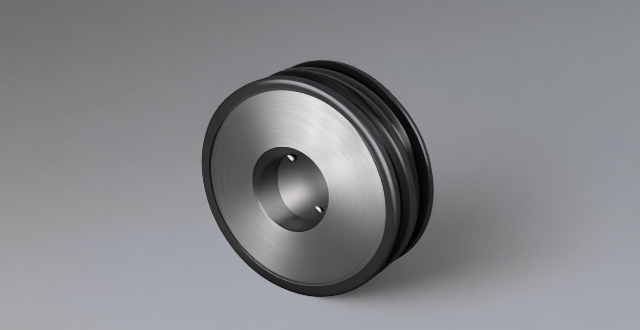

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

Can an AC stepping motor be used in robotics applications ?

AC stepping motors can be used in robotics applications, offering precise control and high torque. However, they have speed limitations and can overheat, requiring cooling mechanisms. Consider application requirements and compatibility with control systems before choosing an AC stepping motor for a robotic project.

Is there a way to measure network latency ?

Measuring network latency is crucial for understanding a network's performance. The ping test, traceroute, and online tools are methods to measure latency. Ping tests estimate the round-trip time, while traceroute identifies bottlenecks in the network path. Online tools provide visual representations of network performance.

What are some common applications for AC stepping motors ?

AC stepping motors have a wide range of applications due to their precise control and high torque output. Here are some common uses: 1. Printers and Plotters: AC stepping motors are used in printers and plotters to move the print head or pen with precision, and they can control the speed of the print head or pen, allowing for variable printing speeds. 2. CNC Machines: In computer numerical control (CNC) machines, AC stepping motors are used to control the path of the cutting tool and adjust the feed rate of the tool, allowing for precise machining of parts. 3. Robotics: AC stepping motors are often used in robotic joints to provide precise movement and positioning, and they can control the force applied by the robot's end effector, allowing for delicate manipulation of objects. 4. Textile Industry: In textile machinery, AC stepping motors are used to feed fabric through the machine at a controlled rate and control the pattern being woven into the fabric by adjusting the position of the weaving elements. 5. Automation Systems: AC stepping motors are used to control the speed and direction of conveyor belts in automation systems, and they are often used as actuators in automated systems, providing precise control over the position and movement of components.

Are there any tools to help diagnose network latency issues ?

Network latency issues can be frustrating and detrimental to the performance of applications and services. Fortunately, there are several tools available that can help diagnose and troubleshoot these issues. Some popular tools used for network latency diagnosis include Ping, Traceroute, MTR (My Traceroute), Netstat, Tcpdump, and Wireshark. Each tool has its own strengths and weaknesses, so it's important to choose the right one based on your specific needs and circumstances. By using these tools effectively, you can identify and resolve latency problems quickly and efficiently.

Have there been any instances where sporting events have led to improved diplomatic relations ?

Sporting events have been used to improve diplomatic relations between countries, bringing people together regardless of their backgrounds or beliefs. Examples include Ping-Pong diplomacy in the 1970s between China and the US, soccer matches promoting peace in the Middle East, the Olympic Truce symbolizing goodwill and cooperation, and rugby matches representing reconciliation and forgiveness.

What is considered high network latency ?

High network latency is a delay in data transmission that can negatively affect the performance of applications and services. It is influenced by various factors such as distance, congestion, hardware performance, bandwidth limitations, QoS settings, and interference. The definition of high latency varies depending on the context, but it is generally considered to be any delay that significantly impacts the usability of applications or services. Identifying high network latency can be done using tools like ping tests or traceroute commands. Mitigating high network latency can involve upgrading hardware, increasing bandwidth, optimizing QoS settings, reducing physical distance, and minimizing interference.

Where can I enjoy haute cuisine in Hong Kong without breaking the bank ?

Hong Kong is a food lover's paradise, offering a wide range of culinary delights at various price points. Here are some budget-friendly options for enjoying haute cuisine in the city: 1. **Tim Ho Wan** - The World's Cheapest Michelin-starred Restaurant offers dim sum dishes like Baked Buns with BBQ Pork for HK$20-50 per dish. 2. **Yung Kee Restaurant** - Affordable Roast Goose is renowned for its crispy and juicy roast goose, with meals costing HK$100-200. 3. **Tai Ping Koon** - Budget-Friendly Seafood Restaurant serves fresh seafood dishes like steamed fish and shrimp with garlic for HK$50-100 per dish. 4. **Lan Fong Yuen** - No-frills Tea House with Reasonable Prices offers traditional Cantonese tea and snacks since 1956, with prices ranging from HK$20-40 per person. 5. **Kau Kee Restaurant** - Affordable Noodles and Congee is known for its beef brisket noodles and congee, with meals costing HK$30-50. 6. **Lin Heung Kuttay** - Cheap and Cheerful Desserts specializes in traditional Chinese desserts like mango pomelo sago soup and durian pudding, with prices ranging from HK$10-30 per dessert. These options prove that you don't have to spend a fortune to enjoy delicious food in Hong Kong.

Is it possible for sports to transcend political differences and bring nations together ?

The article discusses the potential of sports to transcend political differences and bring nations together. It highlights three key ways in which sports can achieve this: through competition, cultural exchange, and diplomacy. The power of sports is demonstrated through various examples, such as the Olympics, World Cup, NBA, Formula One, Ping-Pong Diplomacy, and Peace Games. The article concludes that while political conflicts may still exist outside of sports, these activities provide a platform for positive interactions and collaboration that can lead to lasting change.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

How do hub motors affect the handling and performance of a vehicle ?

Hub motors offer numerous benefits for vehicle handling and performance, including improved weight distribution, torque vectoring, and energy recovery through regenerative braking. These features enhance a vehicle's overall efficiency, stability, and performance. As technology advances, we can expect to see more innovative uses for hub motors in the automotive industry.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

What are the different types of speed controllers available in the market ?

Speed controllers are devices used to regulate the speed of electric motors. They are essential in various industries, including manufacturing, transportation, and energy production. The main types of speed controllers are Eddy Current Drives, DC Drives, AC Drives, and Variable Frequency Drives (VFDs). Each type has its own advantages and disadvantages, such as precise speed control, high efficiency, low maintenance requirements, high initial cost, limited torque capacity, high starting torque, good dynamic response, limited lifespan due to brush wear, low initial cost, long lifespan, wide range of sizes and configurations, less precise speed control compared to DC drives, limited torque capacity at low speeds, energy-efficient operation, sensitive to electrical noise and disturbances. The choice of speed controller depends on the specific application requirements, such as precision, efficiency, and cost.

How does an electronic speed controller work ?

An electronic speed controller (ESC) regulates the speed of an electric motor by controlling the electrical power sent to it. It receives a signal, typically a pulse-width modulation (PWM) signal, which it interprets as a desired speed for the motor. The ESC then converts this low-power signal into a high-power electrical current that can drive the motor. By adjusting the duty cycle of the PWM signal, the ESC controls the motor's speed and torque. It also includes features such as overcurrent protection and cooling to ensure reliable operation. Some ESCs even have a feedback loop to monitor the actual speed of the motor and adjust the power output accordingly.

What are the key parameters to consider when selecting an AC stepping motor ?

Selecting an AC stepping motor involves considering key parameters such as torque, step angle, voltage and current ratings, resolution, size and weight, compatibility with the control system, and cost. These factors ensure the motor meets the application's requirements, providing enough rotational force, handling load demands, fitting within space and weight restrictions, and operating smoothly and precisely. Compatibility with the controller is crucial for proper operation, while cost considerations help stay within budget constraints.

How do you choose the right electromagnetic motor for your needs ?

Choosing the right electromagnetic motor can be a daunting task, but by following these steps, you can make an informed decision that meets your specific needs. First, determine your application, including factors such as load type, required speed, torque, and power output. Then consider the type of motor, such as AC induction, DC, stepper, or servo, each with its own advantages and disadvantages. Next, determine performance requirements, such as speed range, torque requirements, power output, efficiency, and duty cycle. Consider physical constraints, such as size, weight, mounting configuration, environmental conditions, and connectivity options. Finally, evaluate cost and availability, including initial purchase price, maintenance and repair costs, lead times for delivery, and availability of replacement parts and accessories. By following these steps and considering all relevant factors, you can choose the right electromagnetic motor for your specific needs.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.

Can you explain the differences between AC and DC drive motors ?

Electric motors are essential components in various industries, ranging from manufacturing to transportation. Two of the most common types of electric motors are AC (Alternating Current) and DC (Direct Current) drive motors. While both serve similar functions, there are several differences between them that affect their performance and applications. AC and DC drive motors differ in their construction and design, with AC motors having a simpler design with fewer parts, while DC motors have more complex designs with additional components such as brushes and commutators. This complexity can lead to higher maintenance costs for DC motors compared to AC motors. One of the main differences between AC and DC drive motors is their ability to control speed. AC motors generally operate at a fixed speed, which makes them less suitable for applications requiring variable speed control. On the other hand, DC motors offer precise speed control, making them ideal for applications such as robotics, CNC machines, and conveyor systems. AC motors are generally more efficient than DC motors due to their simpler design and lower power consumption. However, the efficiency of a motor also depends on its size, load capacity, and operating conditions. In some cases, DC motors may be more energy-efficient when used in low-power applications or when precise speed control is required. Another difference between AC and DC drive motors is their starting torque. AC motors generally have a higher starting torque than DC motors, which makes them better suited for heavy-duty applications such as pumps, fans, and compressors. DC motors, on the other hand, provide a smoother start-up but may require additional components to achieve the desired starting torque. The cost and availability of AC and DC drive motors vary depending on their size, type, and manufacturer. Generally, AC motors are more widely available and less expensive than DC motors due to their simpler design and lower production costs. However, the total cost of ownership should also consider factors such as maintenance, repair, and energy consumption over the motor's lifetime.

Are there any drawbacks to using permanent magnet motors in certain applications ?

The text discusses the drawbacks of using permanent magnet motors in certain applications, including high cost, demagnetization risk, limited speed range, difficulty in controlling torque and speed, and sensitivity to heat and vibration. These factors make them less suitable for applications where cost is a primary concern, precise control is necessary, or exposure to high temperatures or vibrations is common.