Principle Electrical

What are the basic principles of electrical safety ?

Electrical safety is crucial in daily life, especially with modern technology. Basic principles include understanding electricity, maintaining equipment, using appropriate tools, avoiding direct contact with electricity, keeping away from water, following proper wiring practices, being cautious with extension cords, checking for overheating, and knowing your limitations. Following these principles can prevent accidents and ensure safe use of electrical devices.

What should I do if I encounter an electrical fire ?

In the event of an electrical fire, it is important to stay calm and assess the situation. If possible, turn off the power source causing the fire and use a Class C fire extinguisher. Call for help if the fire cannot be controlled or is spreading rapidly. Evacuate the area quickly and safely, avoiding elevators. Never use water to try to put out an electrical fire, as it can cause electrocution. Keep a safe distance from the fire and follow up with professionals to inspect and repair any damaged electrical systems.

How can I ensure electrical safety in my home ?

Electrical safety is crucial for maintaining a secure home environment. Hire licensed electricians, schedule inspections, keep appliances clean, avoid overloading outlets, be cautious around water, childproof your home, use proper lighting, keep flammable materials away from electrical appliances, and know how to shut off power in emergencies.

What are some common electrical hazards ?

Electrical hazards are a common occurrence in homes, workplaces, and public areas. They can cause serious injuries or even death if not handled properly. Here are some of the most common electrical hazards: ## Overloaded Circuits An overloaded circuit occurs when too many appliances are plugged into a single outlet or circuit. This can cause the circuit to overheat, leading to a fire. It is important to distribute the load across multiple outlets and avoid using extension cords as permanent solutions. ## Faulty Wiring Faulty wiring is another common electrical hazard. This can occur due to poor installation, wear and tear, or damage to the wires. Faulty wiring can cause short circuits, sparks, and electrical shocks. Regular inspections and maintenance by a licensed electrician can help prevent this hazard. ## Water and Electricity Water and electricity do not mix. If water comes into contact with electrical devices or wiring, it can cause electrocution or electrical fires. It is important to keep electrical devices away from water sources and ensure that all electrical appliances are properly grounded. ## Ungrounded Outlets Ungrounded outlets lack a third prong that grounds the outlet to the earth. This can lead to electrical shocks and increase the risk of electrical fires. It is important to have all outlets in your home or workplace grounded for safety. ## Damaged Cords and Plugs Damaged cords and plugs are also common electrical hazards. If a cord is frayed or cracked, it can expose live wires and cause electrical shocks. Similarly, damaged plugs can cause sparks and short circuits. It is important to replace damaged cords and plugs immediately. ## Improper Use of Extension Cords Extension cords should only be used temporarily and never as a permanent solution for powering appliances. Overloading an extension cord can cause it to overheat and start a fire. It is important to use extension cords sparingly and ensure they are rated for the amount of power being drawn through them.

How often should I have my electrical system inspected ?

Electrical system inspections are crucial for ensuring the safety and functionality of your home or business. The frequency of these inspections depends on various factors such as the age and type of property, recent changes, and local regulations. For residential properties, it is recommended to have your electrical system inspected every 5-10 years, but more frequently if you notice any signs of trouble or live in an older home. Commercial properties should have their electrical systems inspected annually due to higher usage and demand. Regular safety checks are also essential for commercial properties to comply with local regulations and protect employees and customers from potential hazards. It is always better to err on the side of caution and schedule regular inspections to maintain the safety and functionality of your electrical system.

How do I properly use and maintain electrical equipment ?

Electrical equipment requires proper use and maintenance to ensure safety, efficiency, and longevity. Key tips include reading the manual, inspecting before use, avoiding overloading, keeping away from water, cleaning regularly, checking wiring, replacing parts as needed, storing properly, unplugging when not in use, using surge protectors, and avoiding DIY repairs for significant issues. Following these guidelines helps extend the lifespan of electrical equipment and minimizes risks associated with their use.

How can I protect my children from electrical hazards ?

The text provides a comprehensive guide on how parents can protect their children from electrical hazards. It emphasizes the importance of education, preventative measures, emergency response, and parental supervision in ensuring electrical safety for kids. The key steps include teaching children about electricity using simple language and visual aids, role-playing safe vs. unsafe scenarios, covering all outlets with plugs or surge protectors, childproofing the home by securing loose wires and unplugging devices when not in use, proper placement of devices away from water sources, regular inspections for faulty wiring, learning first aid including CPR training, keeping emergency numbers handy, supervising young children around electrical devices, and setting rules and boundaries regarding electrical safety. By following these guidelines, parents can significantly reduce the risk of electrical hazards affecting their children, emphasizing that vigilance and proactive measures are crucial for maintaining electrical safety in the family.

What are the safety regulations for electrical work ?

Electrical work involves a high level of risk, and it is essential to follow strict safety regulations to prevent accidents and injuries. Here are some of the key safety regulations for electrical work: - Always wear appropriate personal protective equipment (PPE), such as insulated gloves, safety glasses, and non-conductive shoes. - Turn off the power before starting any electrical work, and use a lockout/tagout system to prevent accidental energization of equipment. - Use insulating materials and tools designed for live work when working near live circuits. - Assess confined spaces for potential hazards before entering and use ventilation systems to maintain safe air quality. - Only qualified personnel should work with high voltage circuits, using specialized tools and following specific procedures for testing and inspection. - Know emergency procedures, including the location of emergency equipment and how to call for help.

What are the OSHA standards for electrical safety in the workplace ?

OSHA has established standards for electrical safety in the workplace to protect employees from hazards associated with electricity. These standards cover training, lockout/tagout procedures, arc flash hazard protection, grounding and bonding, and maintenance of electrical wiring and equipment. Specific requirements vary depending on the type of workplace, such as construction sites, industrial settings, and office environments. By following these standards and implementing appropriate controls, employers can create a safe work environment and reduce the risk of electrical accidents and injuries.

What are the best practices for working with electrical panels and switchboards ?

Electrical panels and switchboards are crucial components of any electrical system, and working with them requires utmost care and attention to detail. Here are some best practices for ensuring safety and efficiency while working on these systems: 1. Understand the system you're dealing with before starting any work. 2. Always turn off power to the panel or switchboard before beginning any work. 3. Use proper tools and equipment, including insulated tools, gloves, and other protective gear. 4. Implement lockout/tagout procedures to prevent accidental energization of the equipment. 5. Work with a partner whenever possible, especially when working with high voltage systems. 6. Inspect the equipment before starting any work, looking for signs of damage, wear, or corrosion. 7. Test the system before re-energizing it after completing your work. 8. Keep detailed records of the work you've done, including what was done, when it was done, and any issues that were encountered. 9. Stay up-to-date on electrical regulations and standards that could affect how you work with electrical panels and switchboards. 10. Attend seminars, workshops, and other training events to maintain your skills and stay safe while working with electrical systems.

Can you explain the working principle of a flow battery for energy storage ?

Flow batteries are a type of rechargeable battery that store energy in two chemical solutions pumped past an ion-exchange membrane. Key components include electrolyte tanks, pumps, and the cell stack. During charging, electrical energy is converted into chemical energy by moving ions across the membrane, storing them as potential gradients. Discharging reverses this process to generate electricity. Flow batteries offer scalability, decoupling of power and energy, long lifespan, and good efficiency but face challenges like cost, maintenance, and size. They are suitable for large-scale energy storage applications.

How do you control the speed and torque of an AC stepping motor ?

The text provides a comprehensive overview of controlling the speed and torque of an AC stepping motor, emphasizing the importance of understanding its basic principles and utilizing appropriate control techniques. Key points include the motor's working principle, torque generation, and step resolution, as well as various control methods such as pulse rate modulation, microstepping, closed-loop control, current limiting, voltage control, and soft start/stop. Practical considerations like drive system compatibility, thermal management, load factors, and safety precautions are also highlighted for optimal motor performance and longevity.

How can I prevent electrical shocks in the workplace ?

To prevent electrical shocks in the workplace, it's crucial to understand risks, use proper equipment, follow safe work practices, provide training, maintain cleanliness, report faulty equipment, and stay informed. Specific actions include identifying hazards, using insulated tools, implementing lockout/tagout procedures, conducting regular inspections, ensuring employee training, and promptly repairing or replacing damaged equipment.

What are the typical故障 of an internal rotor motor, and how can they be fixed ?

Overheating, bearing failure, electrical problems, mechanical wear and tear, and improper installation are common issues with internal rotor motors. Fixes include ensuring proper ventilation and lubrication, replacing worn parts, seeking professional assistance for electrical and installation issues, and regular maintenance to prevent premature failure.

How does fiber optic broadband work ?

Fiber optic broadband is a high-speed internet connection that uses fiber-optic cables to transmit data. It works by converting electrical signals into light signals, which are then sent through the fiber-optic cables. The process involves conversion of electrical signals to light signals using a modem, transmission through fiber-optic cables, amplification of light signals using optical amplifiers, and conversion back to electrical signals using another modem. Fiber optic broadband offers several advantages over other types of internet connections, including higher speeds, greater bandwidth, improved reliability, and longer transmission distances.

How do I safely dispose of old or damaged electrical devices ?

This comprehensive guide outlines steps for safely disposing of old or damaged electrical devices, including identifying the type of device, checking with the manufacturer, contacting local authorities and recycling centers, donating or selling still-functional devices, properly packaging and transporting devices, considering environmental impacts, and avoiding harmful disposal methods.

What are the warning signs of an overloaded electrical circuit ?

Warning Signs of an Overloaded Electrical Circuit include flickering lights, warm or hot outlets and switches, burning smell, tripped circuit breaker or blown fuse, dimming or fading lights, buzzing sounds, and appliances not working properly. These signs indicate excessive current flow in the circuit, which can lead to damage and potential fire hazards. It is important to consult a licensed electrician for inspection and necessary repairs if you suspect an overloaded circuit.

What are the key principles of environmental ethics ?

The text introduces the concept of environmental ethics, which is a branch of philosophy focusing on the moral relationships between humans and the natural environment. It outlines key principles such as respect for nature, sustainability, precautionary principle, intergenerational equity, biodiversity conservation, ethical consumption, ecological justice, holistic thinking, stewardship, and education and awareness. These principles serve as guiding lights in promoting an ethical relationship with the environment, aiming to create a more sustainable and equitable world.

What is a drive motor and how does it work ?

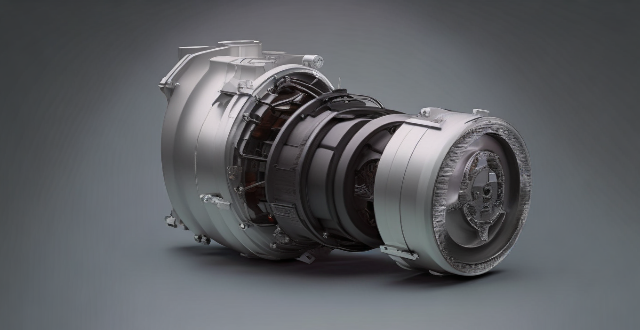

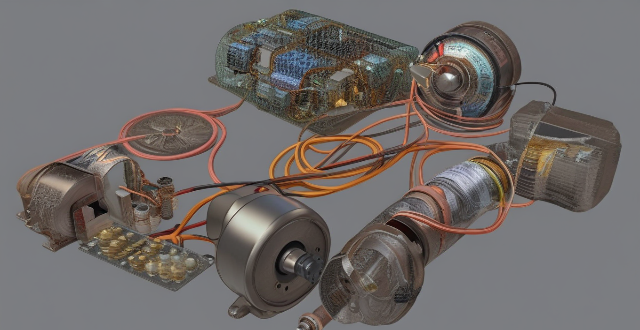

A drive motor, also known as a motor or electric motor, is a device that converts electrical energy into mechanical energy. It operates on the principle of electromagnetism, using magnetic fields to produce motion. Drive motors are used in various applications such as transportation, industrial machinery, and consumer electronics. The working principle of a drive motor is based on **electromagnetic induction**, which refers to the process of generating an electric current within a conductor when it is exposed to a changing magnetic field. In a typical AC (Alternating Current) motor, a rotating magnetic field is created inside the motor using multiple coils of wire connected to an alternating current source. The alternating current causes the direction of the magnetic field produced by each coil to change continuously. As these fields change, they create a rotational force called **torque**, which turns the motor shaft. The interaction between the rotating magnetic field and the stationary part of the motor generates motion. This movement can be harnessed to perform work, such as driving a fan blade or lifting weights. The components of a drive motor include the stator, rotor, bearings, windings, commutator (in DC motors), and shaft. There are several types of drive motors, including DC Motors, AC Motors, Stepper Motors, and Servo Motors. Each type has its advantages and disadvantages, making it suitable for specific applications based on factors like efficiency, size, cost, and control complexity.

What is climate ethics and why is it important in today's world ?

Climate ethics is a branch of philosophy that examines the ethical implications of human activities contributing to global warming and explores ways to mitigate its effects. It matters because it addresses the fundamental question of how we should live our lives and interact with the environment to ensure a sustainable future for all. Key principles of climate ethics include the precautionary principle, intergenerational solidarity, environmental justice, sustainable development, and common but differentiated responsibilities. By embracing these principles and taking action based on them, we can work towards creating a more just, equitable, and sustainable world for all.

How do zinc-carbon batteries work ?

Zinc-carbon batteries are primary, single-use batteries that generate electricity through a chemical reaction involving zinc and carbon. Their construction includes an anode of zinc, a cathode of manganese dioxide mixed with carbon, an electrolyte, a separator, and a container. When in use, zinc is oxidized at the anode, releasing electrons and zinc ions, while the cathode accepts electrons and reduces manganese dioxide. This flow of electrons creates an electrical current. Over time, the battery discharges as the materials are used up, requiring replacement. Proper disposal is crucial to prevent environmental pollution from their heavy metal components.

How does a lead-acid battery work ?

Lead-acid batteries work on the principle of converting chemical energy into electrical energy and vice versa. They consist of an electrolyte, plates, and separators. During charging, an external power source applies a voltage higher than the open-circuit voltage of the battery, causing lead sulfate on the positive plate to be converted back into lead dioxide and on the negative plate into metallic lead. During discharging, when a load is connected to the battery, lead dioxide on the positive plate is reduced to lead sulfate, and metallic lead on the negative plate is oxidized to lead sulfate. The electrons flow from the negative terminal of the battery to the load during discharging and from the positive terminal of the external power source to the positive plate of the battery during charging.

What is a brushless motor ?

Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

What is an electromagnetic motor ?

Electromagnetic motors are electric motors that use electromagnetic force to convert electrical energy into mechanical energy. They consist of a stator (stationary part) and a rotor (rotating part), along with components like a commutator, brushes, and an armature. The operation involves generating magnetic fields, current flow in rotor coils, interaction between these fields, continuous rotation facilitated by the commutator, and mechanical output through the shaft. Types include DC motors, AC motors, stepper motors, and universal motors, each suitable for different applications.