Principle Torque

How do you control the speed and torque of an AC stepping motor ?

The text provides a comprehensive overview of controlling the speed and torque of an AC stepping motor, emphasizing the importance of understanding its basic principles and utilizing appropriate control techniques. Key points include the motor's working principle, torque generation, and step resolution, as well as various control methods such as pulse rate modulation, microstepping, closed-loop control, current limiting, voltage control, and soft start/stop. Practical considerations like drive system compatibility, thermal management, load factors, and safety precautions are also highlighted for optimal motor performance and longevity.

Can you explain the concept of vector control in multi-motor drives ?

Vector control is a method for controlling the speed and torque of electric motors, especially AC motors, in multi-motor drives. It works by decoupling the flux-producing and torque-producing components of the stator current, allowing for independent control of both. This results in improved dynamic response, precise speed regulation, energy efficiency, reduced mechanical stress, and adaptability to different motor types.

How do you troubleshoot common issues with AC stepping motors, such as missing steps or low torque ?

Troubleshooting common issues with AC stepping motors involves addressing problems such as missing steps or low torque. This is done by checking the power supply, examining the drive system, analyzing mechanical components, evaluating control signals, and considering environmental factors. It is important to approach the problem methodically, starting with basic checks before moving on to more complex diagnostics.

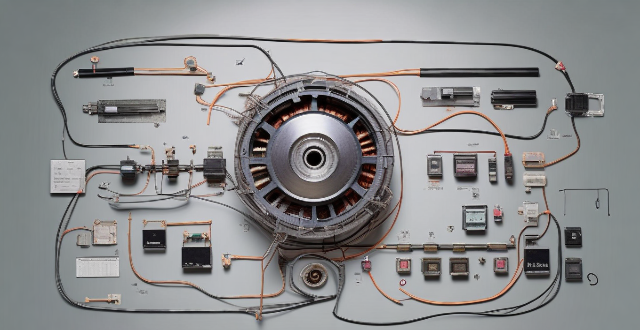

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

What are the key principles of environmental ethics ?

The text introduces the concept of environmental ethics, which is a branch of philosophy focusing on the moral relationships between humans and the natural environment. It outlines key principles such as respect for nature, sustainability, precautionary principle, intergenerational equity, biodiversity conservation, ethical consumption, ecological justice, holistic thinking, stewardship, and education and awareness. These principles serve as guiding lights in promoting an ethical relationship with the environment, aiming to create a more sustainable and equitable world.

How do permanent magnet motors work, and what makes them more efficient ?

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

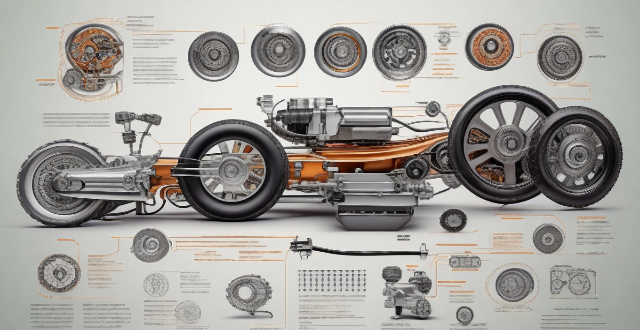

What is a drive motor and how does it work ?

A drive motor, also known as a motor or electric motor, is a device that converts electrical energy into mechanical energy. It operates on the principle of electromagnetism, using magnetic fields to produce motion. Drive motors are used in various applications such as transportation, industrial machinery, and consumer electronics. The working principle of a drive motor is based on **electromagnetic induction**, which refers to the process of generating an electric current within a conductor when it is exposed to a changing magnetic field. In a typical AC (Alternating Current) motor, a rotating magnetic field is created inside the motor using multiple coils of wire connected to an alternating current source. The alternating current causes the direction of the magnetic field produced by each coil to change continuously. As these fields change, they create a rotational force called **torque**, which turns the motor shaft. The interaction between the rotating magnetic field and the stationary part of the motor generates motion. This movement can be harnessed to perform work, such as driving a fan blade or lifting weights. The components of a drive motor include the stator, rotor, bearings, windings, commutator (in DC motors), and shaft. There are several types of drive motors, including DC Motors, AC Motors, Stepper Motors, and Servo Motors. Each type has its advantages and disadvantages, making it suitable for specific applications based on factors like efficiency, size, cost, and control complexity.

What is climate ethics and why is it important in today's world ?

Climate ethics is a branch of philosophy that examines the ethical implications of human activities contributing to global warming and explores ways to mitigate its effects. It matters because it addresses the fundamental question of how we should live our lives and interact with the environment to ensure a sustainable future for all. Key principles of climate ethics include the precautionary principle, intergenerational solidarity, environmental justice, sustainable development, and common but differentiated responsibilities. By embracing these principles and taking action based on them, we can work towards creating a more just, equitable, and sustainable world for all.

Can you explain the working principle of a flow battery for energy storage ?

Flow batteries are a type of rechargeable battery that store energy in two chemical solutions pumped past an ion-exchange membrane. Key components include electrolyte tanks, pumps, and the cell stack. During charging, electrical energy is converted into chemical energy by moving ions across the membrane, storing them as potential gradients. Discharging reverses this process to generate electricity. Flow batteries offer scalability, decoupling of power and energy, long lifespan, and good efficiency but face challenges like cost, maintenance, and size. They are suitable for large-scale energy storage applications.

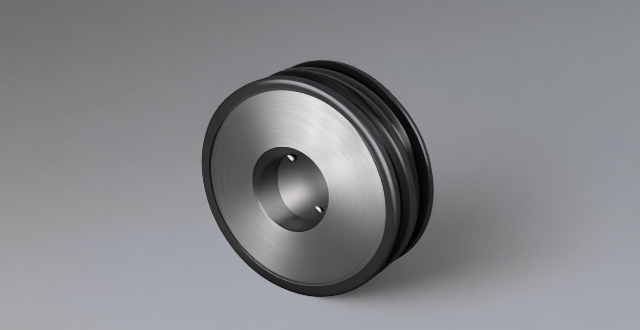

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

How does an internal rotor motor work ?

Internal rotor motors operate through the interaction of magnetic fields produced by their stator and rotor components, generating rotational force and torque. They offer advantages such as high efficiency and precise speed control but also have drawbacks like increased complexity and maintenance requirements.

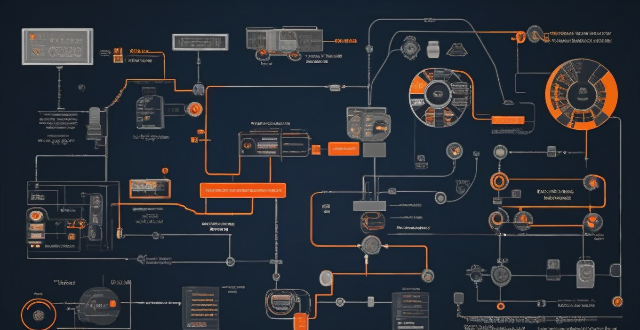

How does a multi-motor drive system work ?

The text explains how a multi-motor drive system works, its components, and benefits. It describes the process of power conversion, control signals, motor operation, mechanical transmission, and feedback adjustment in such systems. The advantages include improved efficiency, increased redundancy, and enhanced control.

How does a hub motor work ?

Hub motors, integral to electric vehicles, operate on electromagnetic principles and Lorentz force. Key components include the stator, rotor, bearings, and controller. When current flows through the stator coils, a magnetic field is generated, which interacts with the rotor's permanent magnets, causing rotation that propels the vehicle. Hub motors are efficient, quiet, and require less maintenance due to their direct drive mechanism and fewer moving parts. However, they can add weight and present cooling challenges. Advancements in technology are expected to enhance their benefits and address limitations.

What are the different types of electromagnetic motors ?

This article discusses the various types of electromagnetic motors, including DC motors (brushed and brushless), AC motors (induction and synchronous), stepper motors (bipolar and unipolar), and servo motors (DC and AC). Each type of motor has unique features and applications, such as power demand, speed range, accuracy, and cost. The choice of motor depends on the specific requirements of the application.

How does a single motor drive work ?

The motor drive converts incoming AC power to DC, controls the motor's speed via PWM, regulates its torque by monitoring current and adjusting voltage, and ensures proper operation through feedback control.

How do hub motors affect the handling and performance of a vehicle ?

Hub motors offer numerous benefits for vehicle handling and performance, including improved weight distribution, torque vectoring, and energy recovery through regenerative braking. These features enhance a vehicle's overall efficiency, stability, and performance. As technology advances, we can expect to see more innovative uses for hub motors in the automotive industry.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

What are the different types of combination motor drives available in the market ?

The article discusses different types of combination motor drives, including AC, DC, servo, and stepper motor drives. It highlights their unique features such as precise speed control, high torque output, regenerative braking, position control, feedback systems, and microstepping capabilities. The article emphasizes the importance of selecting the appropriate type of motor drive based on the specific needs and requirements of the application.

What are the different types of speed controllers available in the market ?

Speed controllers are devices used to regulate the speed of electric motors. They are essential in various industries, including manufacturing, transportation, and energy production. The main types of speed controllers are Eddy Current Drives, DC Drives, AC Drives, and Variable Frequency Drives (VFDs). Each type has its own advantages and disadvantages, such as precise speed control, high efficiency, low maintenance requirements, high initial cost, limited torque capacity, high starting torque, good dynamic response, limited lifespan due to brush wear, low initial cost, long lifespan, wide range of sizes and configurations, less precise speed control compared to DC drives, limited torque capacity at low speeds, energy-efficient operation, sensitive to electrical noise and disturbances. The choice of speed controller depends on the specific application requirements, such as precision, efficiency, and cost.

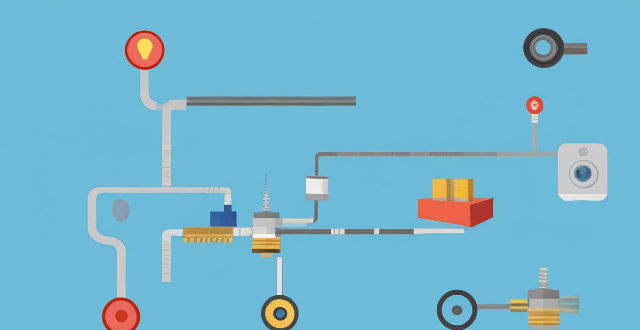

How does an electronic speed controller work ?

An electronic speed controller (ESC) regulates the speed of an electric motor by controlling the electrical power sent to it. It receives a signal, typically a pulse-width modulation (PWM) signal, which it interprets as a desired speed for the motor. The ESC then converts this low-power signal into a high-power electrical current that can drive the motor. By adjusting the duty cycle of the PWM signal, the ESC controls the motor's speed and torque. It also includes features such as overcurrent protection and cooling to ensure reliable operation. Some ESCs even have a feedback loop to monitor the actual speed of the motor and adjust the power output accordingly.

What are the key parameters to consider when selecting an AC stepping motor ?

Selecting an AC stepping motor involves considering key parameters such as torque, step angle, voltage and current ratings, resolution, size and weight, compatibility with the control system, and cost. These factors ensure the motor meets the application's requirements, providing enough rotational force, handling load demands, fitting within space and weight restrictions, and operating smoothly and precisely. Compatibility with the controller is crucial for proper operation, while cost considerations help stay within budget constraints.

How do you choose the right electromagnetic motor for your needs ?

Choosing the right electromagnetic motor can be a daunting task, but by following these steps, you can make an informed decision that meets your specific needs. First, determine your application, including factors such as load type, required speed, torque, and power output. Then consider the type of motor, such as AC induction, DC, stepper, or servo, each with its own advantages and disadvantages. Next, determine performance requirements, such as speed range, torque requirements, power output, efficiency, and duty cycle. Consider physical constraints, such as size, weight, mounting configuration, environmental conditions, and connectivity options. Finally, evaluate cost and availability, including initial purchase price, maintenance and repair costs, lead times for delivery, and availability of replacement parts and accessories. By following these steps and considering all relevant factors, you can choose the right electromagnetic motor for your specific needs.

What are the advantages of using an AC stepping motor compared to a DC stepping motor ?

The text discusses the advantages of using AC stepping motors compared to DC stepping motors. The main points include: 1. **Simplified Drive Circuitry**: AC stepping motors have simpler drive circuitry than DC stepping motors, leading to fewer components and a more streamlined design, which reduces complexity and lowers manufacturing costs. 2. **Higher Torque Output**: AC stepping motors typically offer higher torque output than DC stepping motors, making them ideal for applications requiring high torque at low speeds. This also leads to improved efficiency and reduced energy consumption. 3. **Better Heat Dissipation**: AC stepping motors often have better heat dissipation capabilities due to their larger surface area and improved cooling mechanisms, allowing them to operate at higher temperatures without overheating and extending their lifespan. 4. **Compatibility with Standard AC Power Sources**: AC stepping motors are compatible with standard AC power sources widely available in industrial and commercial settings, eliminating the need for additional power supplies or conversion equipment and simplifying installation. 5. **Lower Maintenance Requirements**: AC stepping motors generally require less maintenance than DC stepping motors, as they have fewer moving parts and simpler drive circuitry, reducing maintenance costs and downtime. Overall, the text highlights that AC stepping motors offer significant benefits over DC stepping motors in terms of simplicity, performance, efficiency, compatibility, and maintenance, making them a popular choice for various applications where precision control and reliability are essential.

How do you choose the right AC stepping motor for your project ?

Choosing the right AC stepping motor requires understanding project needs, selecting the appropriate motor type, ensuring compatibility with control systems, considering physical constraints, evaluating performance characteristics, accounting for environmental factors, managing budgetary considerations, relying on supplier support and reputation, and conducting thorough testing.