Rotor Application

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

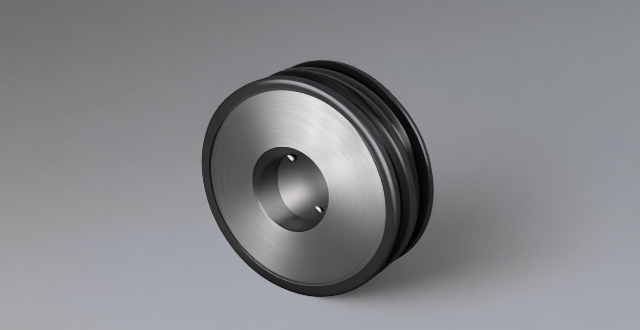

Can you explain the differences between an internal and external rotor motor ?

Motors are crucial components of various mechanical systems, and understanding their types is essential for selecting the appropriate one for a specific application. Two common types of motors are internal rotor motors and external rotor motors. An internal rotor motor has its rotor located inside the stator, while an external rotor motor has its rotor located outside the stator. The main differences between these two types of motors include rotor location, torque output, cooling efficiency, maintenance accessibility, and application suitability. Understanding these differences can help in selecting the appropriate motor type for a given task.

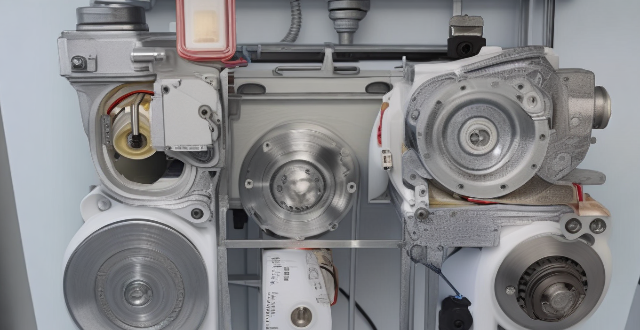

How does an internal rotor motor work ?

Internal rotor motors operate through the interaction of magnetic fields produced by their stator and rotor components, generating rotational force and torque. They offer advantages such as high efficiency and precise speed control but also have drawbacks like increased complexity and maintenance requirements.

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

What are the advantages of using an internal rotor motor ?

An internal rotor motor is a type of electric motor where the rotor is located inside the stator. This design has several advantages over other types of motors, such as external rotor motors or brushed motors. Some of these advantages include higher efficiency, improved heat dissipation, lower noise levels, better control and response, compact design, and reduced maintenance costs. These benefits make internal rotor motors a popular choice for various applications across industries.

How do I choose the right drive motor for my application ?

When selecting a drive motor for your application, considerWhen selecting a drive motor for your application, considerrque and speed, power duty cycle, cost, size, control compatibility, safety compliance, maintenance, and manufacturer reputation. This comprehensive guide helps ensure you choose a motor that meets your needs effectively and efficiently.

How does a co-signer affect my mortgage application ?

A co-signer is a person who signs a loan application along with the primary borrower. The co-signer agrees to take on the responsibility of repaying the loan if the primary borrower fails to do so. In this article, we will discuss how a co-signer affects your mortgage application. The credit score of both the primary borrower and the co-signer plays a significant role in determining the eligibility for a mortgage loan. A co-signer with a good credit score can improve the chances of getting approved for a mortgage loan. However, if the co-signer has a poor credit score, it may negatively impact the loan approval process. The income and debt-to-income ratio (DTI) of both the primary borrower and the co-signer are also important factors that lenders consider when evaluating a mortgage application. If the co-signer has a high income and low DTI, it can help strengthen the application and increase the chances of approval. On the other hand, if the co-signer has a low income or high DTI, it may negatively impact the loan approval process. Lenders also consider the employment history of both the primary borrower and the co-signer when evaluating a mortgage application. A stable employment history can demonstrate financial stability and reliability, which can positively impact the loan approval process. If the co-signer has a stable employment history, it can help strengthen the application and increase the chances of approval. The assets and liabilities of both the primary borrower and the co-signer are also taken into consideration by lenders when evaluating a mortgage application. If the co-signer has significant assets and few liabilities, it can help strengthen the application and increase the chances of approval. However, if the co-signer has significant liabilities or limited assets, it may negatively impact the loan approval process. In conclusion, a co-signer can have a significant impact on your mortgage application. Their credit score, income and DTI, employment history, assets, and liabilities are all factors that lenders consider when evaluating a mortgage application. It is important to choose a co-signer who has a good credit score, stable employment history, and low DTI to increase the chances of getting approved for a mortgage loan.

How can I check the status of my tourist visa application ?

Checking the status of your tourist visa application can be a nerve-wracking experience, especially when you're eagerly anticipating your travel plans. Here's a step-by-step guide to help you through the process: 1. Determine the type of visa you applied for, as different visas might have different checking procedures. 2. Locate the appropriate government website or portal dedicated to visa services where you can check the status of your application. 3. Have your application details ready, such as Application ID Number, Passport Number, and Date of Birth. 4. Enter the required details into the online system on the visa status portal. 5. Submit the form and retrieve the status of your visa application. 6. Interpret the status message, which could indicate that your application has been accepted, is under review, requires administrative processing, has been issued, or has been refused. 7. Follow up if necessary with the embassy or consulate for any delays or further action required. Additional tips include keeping track of timelines, being patient as visa processing times can vary, and staying informed about any events that might affect processing times. By following these steps, you should be able to effectively check the status of your tourist visa application and plan accordingly.

In what applications are internal rotor motors commonly used ?

Internal rotor motors, also known as rotary motors or simply electric motors, are widely used in various applications due to their ability to convert electrical energy into mechanical energy. These motors consist of a stationary component (stator) and a rotating component (rotor), which is located inside the stator. The rotor is driven by electromagnetic forces generated by the interaction between the stator and rotor windings. In conclusion, internal rotor motors play a crucial role across numerous sectors, from industrial manufacturing to domestic appliances and even critical medical equipment. Their versatility makes them an essential component in modern technology advancements.

What documents do I need to provide for a tourist visa application ?

The text provides a list of essential documents required for a tourist visa application, including a passport with at least six months' validity and two blank visa pages, recent passport photographs meeting specific requirements, a completed visa application form, a detailed travel itinerary, proof of financial means, an invitation letter if applicable, travel insurance, and a cover letter explaining the purpose of the visit. The text emphasizes the importance of gathering these documents beforehand to make the application process smoother and increase the chances of success. It also notes that specific requirements may vary by country, so applicants should check the documentation needs and specifications for each item.

Is it necessary to have a return ticket for a tourist visa application ?

The text discusses the importance of a return ticket for a tourist visa application. It states that a return ticket is necessary to ensure the traveler has plans to return to their home country after the completion of their trip. Other documents required for a tourist visa application include a valid passport, hotel reservation, travel itinerary, financial evidence, invitation letter, travel insurance, application form, and photo. The return ticket is considered important as it shows the embassy or consulate that the traveler plans to return to their home country after their trip, reduces the chances of overstaying their visa period, assures the authorities of departure arrangements, and maintains the integrity of visa policies. If a traveler cannot provide a return ticket at the time of application, there is a high probability of visa rejection. However, an onward journey ticket can be provided as an alternative. Alternatives to a return ticket include one-way tickets, open-ended tickets, refundable tickets, and onward journey tickets. To ensure the availability of a return ticket, travelers should book in advance, choose flexible dates, opt for refundable tickets, and check with airlines about their policies. Not providing a return ticket can lead to visa rejection, blacklisting, impact future applications, and financial losses. Travel agents can assist in getting a return ticket or suggesting alternatives but may charge additional fees.

How can I choose the right combination motor drive for my application ?

When selecting a combination motor drive for your application, consider factors such as the type of motor (AC, DC, stepper, or servo), application requirements (load characteristics, speed and torque needs, control precision), appropriate drive technology (VFDs, electronic speed controls, stepper motor drives, servo amplifiers), compatibility and integration with existing systems, performance features (efficiency, dynamic response, protection features), budget and cost considerations (initial and operating costs), and seek professional advice from manufacturers and technical support.

What are some common mistakes to avoid when rushing through makeup application ?

When rushing through makeup application, common mistakes includeWhen rushing through makeup application, common mistakes include the wrong tools, not blend not blending properly, choosing the wrong shade or formula, ignoring eyebrows, and applying too much product. Taking your time and following these tips can help avoid these mistakes and ensure a flawless finish every time.

What kinds of questions should I expect during the insurance application process ?

When applying for insurance, you will be asked a variety of questions to assess your risk level and determine the appropriate coverage and premiums. These questions cover personal information, employment details, health history, lifestyle habits, driving record, insurance history, financial information, beneficiaries and dependents, and additional questions related to hobbies, travel plans, and pets. Honesty is crucial when answering these questions as providing false information can result in denied claims or policy cancellation. It's essential to review your application carefully before submitting it to ensure all information is accurate and complete.

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

What are the key factors to consider when selecting a permanent magnet motor for a specific application ?

When selecting a permanent magnet motor for a specific application, several key factors must be considered to ensure optimal performance and efficiency. These factors include application requirements, efficiency and performance, size and weight, temperature range and cooling, control and feedback systems, cost and budget, reliability and durability, and compatibility with other system components. By carefully considering these key factors when selecting a permanent magnet motor for your specific application, you can ensure that you choose a motor that meets your needs in terms of performance, efficiency, size, cooling requirements, control options, cost, reliability, and compatibility with other system components.

What are the key factors to consider when designing an energy storage system for a specific application ?

When designing an energy storage system (ESS) for a specific application, key factors to consider include capacity (power and energy requirements, discharge rate), efficiency (round-trip efficiency, self-discharge rate), reliability (cycle life, safety), cost (capital expenses, operating expenses), environmental impact (sustainability, emissions), and scalability (modular design, flexibility). These considerations will ensure the ESS meets application needs while operating efficiently, reliably, and sustainably.

How do I maintain my internal rotor motor to ensure its longevity ?

Maintaining an Internal Rotor Motor for Longevity involves regular cleaning, inspection, lubrication, and checks on critical components. Proper care can extend the motor's lifespan and prevent costly repairs. Cleaning includes removing dust and debris with a soft cloth and compressed air. Deep cleaning is recommended when there are signs of overheating or reduced performance. Inspections should check for visible damage, wear, insulation resistance, and tight connections. Lubricating moving parts and changing lubricants as needed is essential. Bearings should be checked for wear and replaced if necessary, while cooling systems should be inspected for blockages or leaks. Seal integrity should also be verified. Performance testing and preventive replacement of worn parts can save time and money in the long run. Environmental considerations such as keeping the motor in a clean, dry, and temperate environment should also be taken into account. By following these steps, optimal performance and longevity of the internal rotor motor can be ensured.

What are the typical故障 of an internal rotor motor, and how can they be fixed ?

Overheating, bearing failure, electrical problems, mechanical wear and tear, and improper installation are common issues with internal rotor motors. Fixes include ensuring proper ventilation and lubrication, replacing worn parts, seeking professional assistance for electrical and installation issues, and regular maintenance to prevent premature failure.

Are there any special safety precautions I should take when working with an internal rotor motor ?

The text discusses safety precautions for working with internal rotor motors. The key points include wearing appropriate personal protective equipment (PPE), disconnecting the power source before starting work, using insulated tools and gloves when working with live electrical components, using proper lifting techniques and equipment when moving heavy motors or components, avoiding contact with moving parts while the motor is running, handling lubricants or coolants carefully to avoid spills or skin contact, storing chemicals in a well-ventilated area away from heat sources and ignition sources, following proper disposal procedures for waste materials generated during maintenance or repair work, working in a well-ventilated area to minimize exposure to fumes or dust, using vacuum cleaners or other collection devices to capture debris and minimize cleanup time, and disposing of hazardous waste materials according to local regulations and guidelines.

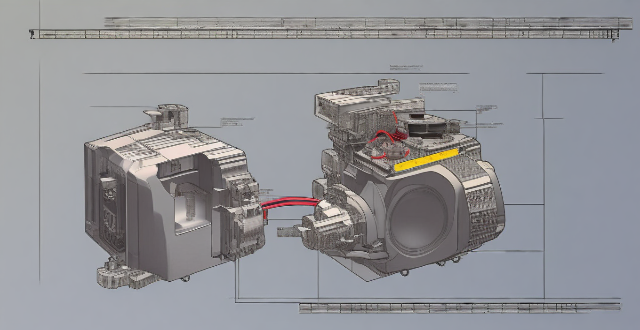

How is an electromagnetic motor designed and constructed ?

Design and construction of an electromagnetic motor involves selecting appropriate components, determining specifications, choosing the type of motor, designing the stator and rotor, calculating winding patterns, assembling the motor, installing a commutator if applicable, connecting wiring and control electronics, testing and troubleshooting, and finalizing and optimizing the design. The key components include the stator, rotor, bearings, commutator, and armature. The steps ensure that the motor meets the required specifications and operates efficiently for its intended use.

How can I increase my chances of getting a scholarship ?

To increase your chances of getting a scholarship, researchTo increase your chances of getting a scholarship, research strong academic record, engage in engage in extracurricular activities and community service, prepare compelling application materials including personal statements and recommendations, and stay organized throughout the application process.

What are the common mistakes to avoid when applying for scholarships ?

When applying for scholarships, it's important to avoid common mistakes that could harm your chances of receiving financial aid. Key points include ensuring accuracy and completeness of your application, submitting on time, writing clear and tailored essays, meeting eligibility criteria, customizing each application, seeking recommendations early, showing financial need, not overlooking smaller awards, following up appropriately, and maintaining integrity without plagiarism or dishonesty. By avoiding these pitfalls, you can present yourself as a diligent and deserving candidate for scholarship opportunities.

What is the difference between a bipolar and unipolar AC stepping motor ?

AC stepping motors are widely used in various applications such as robotics, CNC machines, and automation systems. They convert electrical pulses into mechanical movements with high precision and repeatability. There are two main types of AC stepping motors: bipolar and unipolar. This article will discuss the differences between these two types of motors. Bipolar AC stepping motors have two windings that are connected in series or parallel. Each winding is energized by an alternating current (AC) source, which creates a magnetic field. The direction of the magnetic field depends on the polarity of the current flowing through the windings. By changing the polarity of the current flowing through the windings, the direction of rotation can be reversed. Bipolar AC stepping motors have several advantages over unipolar motors, including higher torque output at lower speeds, better heat dissipation due to larger surface area of the windings, and more efficient use of electrical energy due to lower resistance of the windings. Unipolar AC stepping motors have only one winding that is energized by an alternating current (AC) source. The direction of the magnetic field created by this winding is always the same, regardless of the polarity of the current flowing through it. Unlike bipolar motors, unipolar motors cannot change the direction of rotation without additional hardware. Unipolar AC stepping motors have some advantages over bipolar motors, including simpler control circuitry since only one winding needs to be controlled, lower cost due to fewer components required for operation, and smaller size and weight, making them suitable for compact applications. In conclusion, bipolar and unipolar AC stepping motors differ in terms of their number of windings, ability to reverse direction, torque output, heat dissipation, efficiency, control circuitry complexity, cost, and size/weight. Depending on the specific requirements of your application, you may choose either type of motor based on these factors.

What are the different types of electromagnetic motors ?

This article discusses the various types of electromagnetic motors, including DC motors (brushed and brushless), AC motors (induction and synchronous), stepper motors (bipolar and unipolar), and servo motors (DC and AC). Each type of motor has unique features and applications, such as power demand, speed range, accuracy, and cost. The choice of motor depends on the specific requirements of the application.

How do I write a successful scholarship application letter ?

This guide provides tips on how to write a successful scholarship application letter, including an introduction that grabs the reader's attention and highlights academic achievements, extracurricular activities, and community involvement. The body of the letter should focus on these areas, highlighting strengths and accomplishments, while the conclusion summarizes main points and reiterates why the candidate is a strong choice for the scholarship. The closing should be polite and include contact information.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

How can I simplify my makeup bag for faster application ?

Simplifying your makeup bag can save you time and make your daily routine more efficient. Here are some tips on how to simplify your makeup bag for faster application: 1. **Declutter Your Makeup Bag**: Remove expired or unused products, keep only the essentials that you use regularly, and consider multi-purpose products that can serve multiple functions. 2. **Choose Multi-Purpose Products**: Use a tinted moisturizer instead of foundation and concealer, choose a blush that doubles as an eyeshadow, and look for lip products that can also be used as a blush or highlighter. 3. **Invest in Quality Brushes**: High-quality brushes can help you apply makeup more quickly and efficiently. Choose versatile brushes that can be used for multiple purposes and invest in a good brush cleaner to maintain their quality. 4. **Organize Your Makeup Bag**: Use dividers or compartments to keep your products organized, group similar products together, and keep your most frequently used items easily accessible. 5. **Streamline Your Routine**: Focus on the features you want to emphasize, practice quick techniques, and set a timer for yourself to challenge yourself to complete your routine faster each day. 6. **Consider Minimalism**: Embrace a minimalist approach to makeup by focusing on enhancing your natural features rather than covering them up, using neutral colors that work well with your skin tone, and avoiding trends that require multiple steps or products. By following these steps, you can simplify your makeup bag and streamline your routine for faster application. Remember, less is often more when it comes to makeup, and a simplified routine can lead to a more confident and polished look.

How do I choose the right speed controller for my application ?

Choosing the right speed controller for your application involves considering factors such as the type of control needed, power requirements, performance specifications, compatibility with other system components, and cost-effectiveness. Open-loop systems are simpler and less expensive but less accurate, while closed-loop systems offer higher accuracy at a higher cost and complexity. Power considerations include load inertia, duty cycle, and peak power. Performance factors include accuracy, response time, and stability. Compatibility issues involve motor type, control signals, and mounting options. Lastly, weigh the initial cost against long-term reliability and maintenance expenses to ensure you select a speed controller that meets your needs and budget.