Rotor Efficiency

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

How does an internal rotor motor work ?

Internal rotor motors operate through the interaction of magnetic fields produced by their stator and rotor components, generating rotational force and torque. They offer advantages such as high efficiency and precise speed control but also have drawbacks like increased complexity and maintenance requirements.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

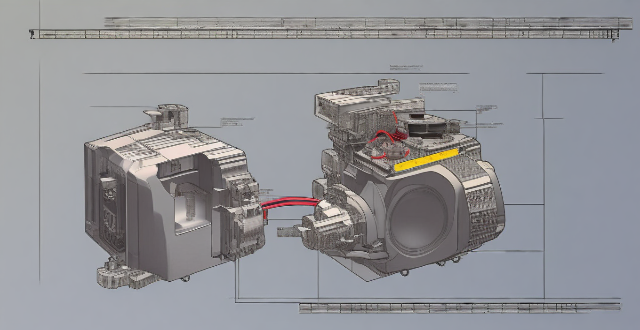

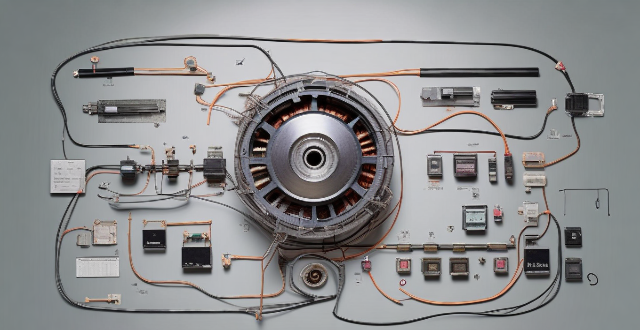

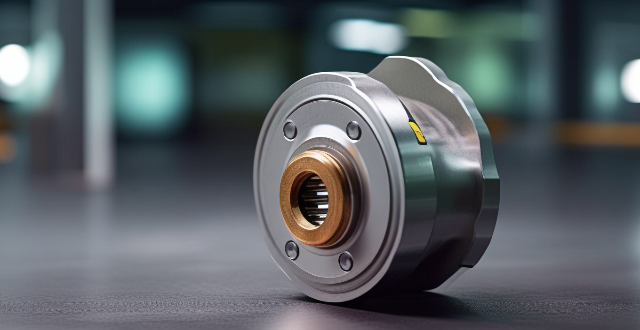

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

What are the advantages of using an internal rotor motor ?

An internal rotor motor is a type of electric motor where the rotor is located inside the stator. This design has several advantages over other types of motors, such as external rotor motors or brushed motors. Some of these advantages include higher efficiency, improved heat dissipation, lower noise levels, better control and response, compact design, and reduced maintenance costs. These benefits make internal rotor motors a popular choice for various applications across industries.

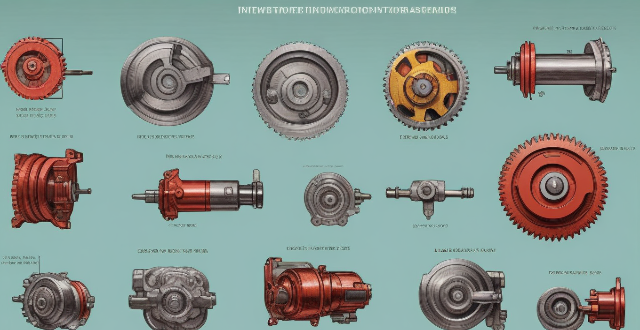

Can you explain the differences between an internal and external rotor motor ?

Motors are crucial components of various mechanical systems, and understanding their types is essential for selecting the appropriate one for a specific application. Two common types of motors are internal rotor motors and external rotor motors. An internal rotor motor has its rotor located inside the stator, while an external rotor motor has its rotor located outside the stator. The main differences between these two types of motors include rotor location, torque output, cooling efficiency, maintenance accessibility, and application suitability. Understanding these differences can help in selecting the appropriate motor type for a given task.

In what applications are internal rotor motors commonly used ?

Internal rotor motors, also known as rotary motors or simply electric motors, are widely used in various applications due to their ability to convert electrical energy into mechanical energy. These motors consist of a stationary component (stator) and a rotating component (rotor), which is located inside the stator. The rotor is driven by electromagnetic forces generated by the interaction between the stator and rotor windings. In conclusion, internal rotor motors play a crucial role across numerous sectors, from industrial manufacturing to domestic appliances and even critical medical equipment. Their versatility makes them an essential component in modern technology advancements.

What are the typical故障 of an internal rotor motor, and how can they be fixed ?

Overheating, bearing failure, electrical problems, mechanical wear and tear, and improper installation are common issues with internal rotor motors. Fixes include ensuring proper ventilation and lubrication, replacing worn parts, seeking professional assistance for electrical and installation issues, and regular maintenance to prevent premature failure.

How does the design of a DC brushed motor impact its performance and efficiency ?

The performance and efficiency of a DC brushed motor are significantly influenced by its design. Key factors include the materials used, winding configuration, magnet strength, bearing type, and cooling system. Materials such as silicon steel for stator cores and carbon steel or aluminum alloys for rotor cores affect magnetic properties and mechanical strength. Winding configuration, including the number of poles and winding type (lap or wave), determines speed and torque characteristics. Magnet strength, shape, and placement impact torque production and power density. Bearing type (ball or roller) affects precision, friction, and load capacity. Finally, proper cooling through active or passive methods is essential for preventing overheating during operation. Overall, careful consideration of these design elements is crucial for achieving desired motor performance and efficiency goals.

How can circular economy policies improve resource efficiency ?

Circular economy policies enhance resource efficiency by promoting sustainable practices like product redesign, encouraging reuse and sharing, maximizing recycling, reducing waste, supporting innovation, and building capacity for sustainable practices.

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

How do I maintain my internal rotor motor to ensure its longevity ?

Maintaining an Internal Rotor Motor for Longevity involves regular cleaning, inspection, lubrication, and checks on critical components. Proper care can extend the motor's lifespan and prevent costly repairs. Cleaning includes removing dust and debris with a soft cloth and compressed air. Deep cleaning is recommended when there are signs of overheating or reduced performance. Inspections should check for visible damage, wear, insulation resistance, and tight connections. Lubricating moving parts and changing lubricants as needed is essential. Bearings should be checked for wear and replaced if necessary, while cooling systems should be inspected for blockages or leaks. Seal integrity should also be verified. Performance testing and preventive replacement of worn parts can save time and money in the long run. Environmental considerations such as keeping the motor in a clean, dry, and temperate environment should also be taken into account. By following these steps, optimal performance and longevity of the internal rotor motor can be ensured.

Are there any special safety precautions I should take when working with an internal rotor motor ?

The text discusses safety precautions for working with internal rotor motors. The key points include wearing appropriate personal protective equipment (PPE), disconnecting the power source before starting work, using insulated tools and gloves when working with live electrical components, using proper lifting techniques and equipment when moving heavy motors or components, avoiding contact with moving parts while the motor is running, handling lubricants or coolants carefully to avoid spills or skin contact, storing chemicals in a well-ventilated area away from heat sources and ignition sources, following proper disposal procedures for waste materials generated during maintenance or repair work, working in a well-ventilated area to minimize exposure to fumes or dust, using vacuum cleaners or other collection devices to capture debris and minimize cleanup time, and disposing of hazardous waste materials according to local regulations and guidelines.

How do international standards and certifications affect industrial energy efficiency practices ?

International standards and certifications significantly influence industrial energy efficiency practices by setting uniform benchmarks, driving innovation, enhancing reputation, promoting transparency, supporting regulatory compliance, and leveraging resource efficiency. These standards provide a framework for continuous improvement, drive technological advancements, expand market opportunities, ensure accountability, align with policies, reduce waste, and offer cost benefits. As sustainability becomes a global priority, adherence to these standards will be crucial for industrial competitiveness and success.

How does a speed controller contribute to energy efficiency in machinery ?

Speed controllers enhance energy efficiency in machinery by reducing energy consumption, improving motor efficiency, optimizing processes, and minimizing standby power use.

Are there any specific diets that enhance exercise efficiency ?

Yes, there are specific diets that can enhance exercise efficiency. These include a high-carbohydrate diet for energy, a low-fat diet for weight management and cardiovascular health, a high-protein diet for muscle recovery and maintenance, and a plant-based diet for optimal nutrient intake. Examples of foods in each diet category are provided, along with the benefits they offer for exercise efficiency. It is recommended to consult with a healthcare professional before starting any new diet plan.

What are the current building energy efficiency standards ?

The text discusses building energy efficiency standards, which are regulations and guidelines designed to reduce energy consumption. These standards promote sustainable development, reduce greenhouse gas emissions, and improve indoor air quality. The text lists seven key areas for improving energy efficiency: insulation and air tightness, heating, ventilation, and air conditioning systems, lighting systems, renewable energy sources, water efficiency, building materials and construction practices, and energy management and monitoring. Each area includes specific strategies and technologies that can be employed to increase energy efficiency.

How can Smart Grid Technology improve energy efficiency ?

Smart grid technology is transforming the energy sector by integrating advanced communication technologies, automated controls, and innovative sensors to create a more efficient, reliable, and sustainable energy system. Key features of smart grid technology include Advanced Metering Infrastructure (AMI), Distributed Energy Resources (DERs), Demand Response (DR) Programs, and Electric Vehicles (EVs). The benefits of smart grid technology on energy efficiency include improved load management through peak shaving, demand side management, and dynamic pricing; increased renewable energy integration through microgrids, grid balancing, and energy storage systems; optimized transmission and distribution through self-healing networks, predictive maintenance, and reduced transmission losses; and enhanced customer engagement and participation through consumer education, incentives for energy efficiency, and community solar programs. Overall, smart grid technology offers numerous opportunities to improve energy efficiency across various sectors of the energy industry while transitioning towards a more sustainable future with reliable and efficient energy delivery for all consumers.

How have building energy efficiency standards evolved over time ?

The evolution of building energy efficiency standards has been significant over the years, with a focus on reducing energy consumption and environmental impact. Early beginnings saw little consideration for energy consumption, leading to high utility bills and greenhouse gas emissions. The rise of energy conservation in the 1970s led to the development of the first building energy efficiency standards, focusing on measures such as improved insulation and efficient heating and cooling systems. The advent of green buildings in the 1990s brought new standards that minimized environmental impact through the use of renewable energy sources and sustainable materials. Technology has played a significant role in improving energy efficiency, with advances such as smart thermostats and LED lighting. Looking to the future, there is likely to be a greater emphasis on reducing energy consumption in buildings, leading to stricter standards and the development of new technologies. Overall, building energy efficiency standards have evolved to become an essential part of modern building design and construction.

How has the adoption of Industry 4.0 technologies influenced energy efficiency in manufacturing ?

Industry 4.0 technologies significantly impact energy efficiency in manufacturing by enabling precision and optimization, data-driven decision making, resource management, promoting sustainability, and enhancing employee engagement. These advancements contribute to a future where smart manufacturing and sustainability are intertwined.

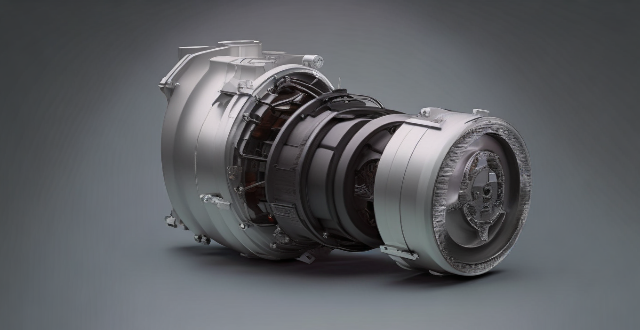

Can a DC brushed motor be used for high-power applications such as electric vehicles or aircraft ?

DC brushed motors have advantages such as simplicity, reliability, and cost-effectiveness. However, they face challenges in high-power applications like electric vehicles or aircraft due to limited power output, efficiency issues, and maintenance concerns. Alternatives like brushless motors and switched reluctance motors are better suited for these scenarios due to their higher power density, improved efficiency, and reduced maintenance requirements.

How can governments promote energy efficiency through policies and incentives ?

Energy efficiency is crucial for sustainable development, and governments can drive it through various policies and incentives. Implementing energy efficiency standards like MEPS and labeling programs, providing financial incentives such as tax credits and grants, enforcing regulatory measures including energy audits and carbon pricing, enhancing public awareness and education, supporting R&D, and fostering international cooperation are effective strategies. These measures can lead to a more sustainable future with reduced environmental impact and increased economic benefits.

How does a brushless motor work ?

Brushless motors, also known as BLDC motors, are electric motors that use an electronic controller to switch the current in their stator windings. They consist of three main components: the rotor, stator, and electronic controller. The working principle of a brushless motor involves initial rotation, commutation, and maintaining rotation. Brushless motors offer several advantages over traditional brushed motors, including higher efficiency, longer lifespan, better performance, and lower maintenance.

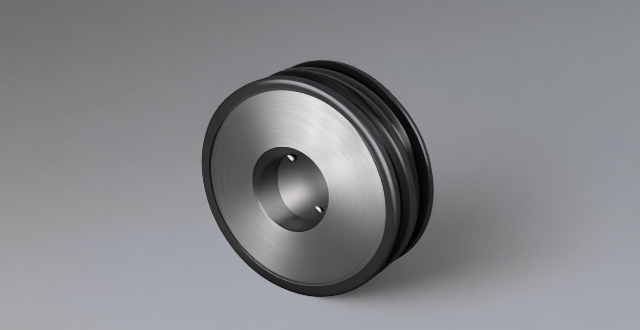

How do permanent magnet motors work, and what makes them more efficient ?

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

How do smart grids help in achieving better energy efficiency ?

Smart grids, through their advanced digital communication technology, play a pivotal role in enhancing energy efficiency. They achieve this by optimizing power generation and distribution, managing energy consumption effectively, improving system reliability, encouraging sustainable practices, and leveraging data analytics. Features like demand response, distributed generation, smart meters, load balancing, peak shaving, self-healing capabilities, predictive maintenance, dynamic pricing, and electric vehicle integration contribute to these efficiency improvements. As we move towards a more connected future, smart grids will continue to drive efforts towards a more energy-efficient global landscape.

How do building energy efficiency standards affect the construction industry ?

Building energy efficiency standards have a significant impact on the construction industry by affecting cost implications, design philosophy, regulatory compliance, and market trends. These standards require higher initial costs due to advanced technologies and materials but offer long-term benefits like reduced energy consumption and maintenance costs. They also shift the focus of design towards energy performance and sustainability, leading to integrated design processes and innovative solutions. Compliance with these standards is crucial to avoid penalties and legal issues, while certifications like LEED or WELL can provide a competitive advantage. Finally, building energy efficiency standards influence market trends by driving demand for sustainable construction methods and educating clients about their benefits.

What is a brushless motor ?

Brushless motors, also known as BLDC (Brushless Direct Current) motors, are electric motors that use an electronic controller to switch the current in their stator windings. They have higher efficiency, longer lifespan, higher power density, lower maintenance requirements, and quieter operation compared to brushed motors. The working principle of a brushless motor involves three main components: the rotor, stator, and electronic controller. Brushless motors are used in various applications, including aircraft, automotive, appliances, and industrial equipment.

How does an electromagnetic motor work ?

The article provides a comprehensive overview of how an electromagnetic motor works, including its basic components such as the stator, rotor, bearings, commutator (in DC motors), and armature (in AC motors). It explains the operating principles in four steps: applying electrical energy to create a magnetic field around the stator coils, the interaction between the magnetic fields of the stator and rotor causing the Lorentz force, the rotation of the rotor as it tries to align its magnetic poles with those of the stator, and maintaining consistent rotation through current reversal by the commutator in DC motors or changing polarity in AC motors. The article also discusses different types of electromagnetic motors like DC motors, AC motors, stepper motors, synchronous motors, and induction motors, highlighting their unique characteristics and suitability for various applications based on efficiency, power requirements, and control complexity.

How do distributed energy systems contribute to energy efficiency and sustainability ?

Distributed energy systems (DES) play a significant role in improving energy efficiency and sustainability. DES refers to a comprehensive energy utilization system located near the end-users, which can operate independently or in conjunction with the grid. It encompasses various technologies such as combined heat and power (CHP), renewable energy, energy storage, and fuel cells. Here is a detailed exploration of how distributed energy systems contribute to energy efficiency and sustainability: 1. **High Energy Efficiency** - **Combined Heat and Power (CHP)**: CHP systems generate both electricity and heat simultaneously, providing an overall efficiency of up to 80%-90%. This is considerably higher than traditional centralized power plants, which typically have an efficiency of around 40% for advanced coal-fired power plants. - **Energy Cascade Utilization**: Distributed energy systems utilize energy cascading, where the byproducts of one process are used as inputs for another. For example, waste heat from electricity generation is used for heating or cooling, maximizing energy utilization. - **Reduced Transmission Losses**: Due to their proximity to consumers, DES reduces the need for long-distance transmission of electricity, thereby minimizing transmission losses compared to centralized power systems. 2. **Environmental Protection** - **Low Emissions**: Distributed energy systems often use clean energy sources like natural gas, solar, and wind, which have lower emissions compared to traditional coal or oil combustion. - **Renewable Energy Integration**: Distributed energy systems can easily integrate renewable energy sources like solar panels and wind turbines, promoting the use of sustainable energy. - **Waste Reduction**: By using waste heat and integrating multiple forms of energy production, DES helps reduce energy waste and its associated environmental impact. 3. **Economic Benefits** - **Cost Savings**: Distributed energy systems can reduce energy costs by decreasing transmission and distribution expenses. They also provide more stable energy prices compared to fluctuating grid rates. - **Infrastructure Investment Reduction**: Since DES requires less infrastructure compared to large-scale power plants and transmission networks, it can lead to significant cost savings in infrastructure investment. - **Market Potential**: The development of DES has opened up new markets and business opportunities, especially in the sale and maintenance of distributed energy equipment. 4. **Enhanced Reliability and Resilience** - **Decentralized Architecture**: The decentralized nature of DES means that if one system fails, others can still operate, ensuring continuous energy supply. - **Storm and Disaster Resilience**: During large-scale disasters or extreme weather events, DES can serve as a crucial energy source when centralized power systems fail. 5. **Promotion of Smart Grid Development** - **Integration with Smart Grids**: Distributed energy systems can be integrated with smart grids, enabling two-way flows of electricity and information, which enhances overall grid efficiency and responsiveness. - **Demand Response Management**: DES allows for better demand response management, where consumption can be adjusted based on real-time supply and demand conditions, further enhancing energy efficiency. Additionally, there are several challenges and considerations for the widespread adoption of distributed energy systems: - **Technical Challenges**: The integration of multiple energy sources requires advanced technical expertise and sophisticated control systems. - **Policy Support**: While policies increasingly support DES, more comprehensive regulations and incentives are needed to encourage wider adoption. - **Economic Viability**: Although DES offers economic benefits, the initial investment can be high, which may limit access for some users. In summary, distributed energy systems contribute significantly to energy efficiency and sustainability through high energy utilization efficiency, environmental protection, economic benefits, enhanced reliability and resilience, and promotion of smart grid development. Despite certain challenges, the advantages of DES make it a critical component of future energy strategies.

What is the efficiency of an electromagnetic motor compared to other types of motors ?

This article compares the efficiency of an electromagnetic motor with other types of motors such as DC motors, AC motors, stepper motors, and servo motors. Electromagnetic motors have a high efficiency rate, typically ranging from 80% to 95%, making them suitable for applications where energy consumption is a concern. DC motors have lower efficiency rates, typically around 50% to 70%, while AC motors have higher efficiency rates, up to 95% or more, but are generally less efficient than electromagnetic motors due to losses in the windings and core. Stepper motors have relatively low efficiency rates compared to other types of motors, typically around 30% to 50%, while servo motors have moderate efficiency rates, typically around 60% to 80%. Overall, the choice of motor depends on various factors such as cost, size, weight, and required performance characteristics.