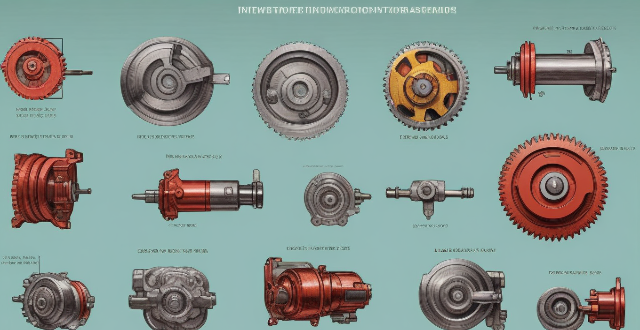

Rotor Types

Can you explain the differences between an internal and external rotor motor ?

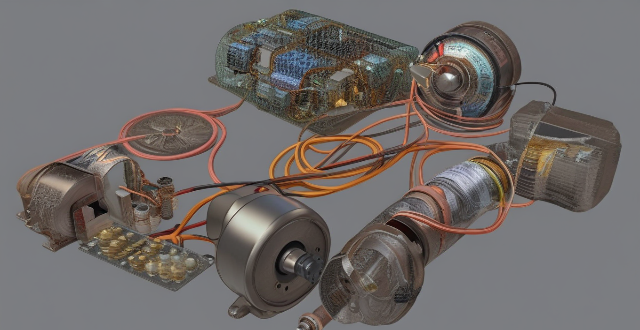

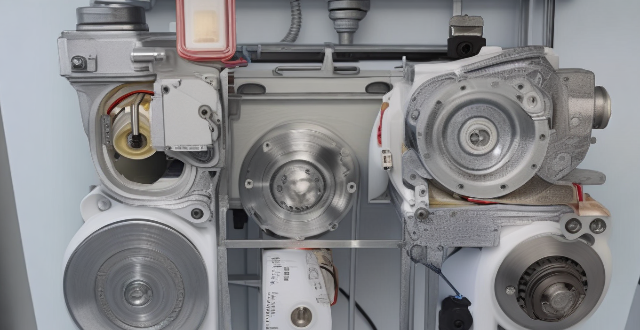

Motors are crucial components of various mechanical systems, and understanding their types is essential for selecting the appropriate one for a specific application. Two common types of motors are internal rotor motors and external rotor motors. An internal rotor motor has its rotor located inside the stator, while an external rotor motor has its rotor located outside the stator. The main differences between these two types of motors include rotor location, torque output, cooling efficiency, maintenance accessibility, and application suitability. Understanding these differences can help in selecting the appropriate motor type for a given task.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

What is an internal rotor motor ?

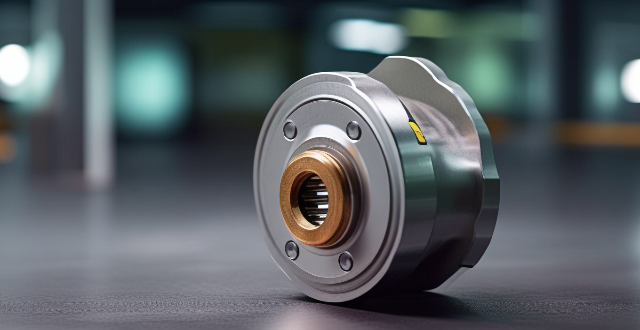

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

How does an internal rotor motor work ?

Internal rotor motors operate through the interaction of magnetic fields produced by their stator and rotor components, generating rotational force and torque. They offer advantages such as high efficiency and precise speed control but also have drawbacks like increased complexity and maintenance requirements.

What are the advantages of using an internal rotor motor ?

An internal rotor motor is a type of electric motor where the rotor is located inside the stator. This design has several advantages over other types of motors, such as external rotor motors or brushed motors. Some of these advantages include higher efficiency, improved heat dissipation, lower noise levels, better control and response, compact design, and reduced maintenance costs. These benefits make internal rotor motors a popular choice for various applications across industries.

What is an AC stepping motor and how does it work ?

An AC stepping motor is a type of electric motor that operates on alternating current and moves in discrete steps. It is commonly used in applications requiring precise control, such as robotics, CNC machines, 3D printers, and automation systems. The motor's movement is achieved by energizing its coils in a specific sequence, causing the rotor to turn a fixed angle for each step. The components of an AC stepping motor include the stator, rotor, and drive system. The stator is the stationary part of the motor containing coils or windings. The rotor is the rotating part of the motor, which has magnetic teeth. The drive system controls the sequence and timing of electrical pulses sent to the stator coils. The operational principle of an AC stepping motor involves winding energization, rotor alignment, stepping action, and repeating sequence. When an electrical current is applied to the stator windings, it creates a magnetic field. The magnetic field interacts with the rotor's magnetic teeth, causing them to align with the stator's field. By changing the sequence of the energized coils, the rotor is forced to rotate to a new position where the teeth again align with the stator's magnetic field. Continuously changing the energized coils causes the rotor to move in a series of small steps. There are two phases of operation for an AC stepping motor: single phase and multi-phase. Single phase operates using only one phase of AC power, typically for simpler applications. Multi-phase uses multiple phases of AC power for more complex movements and higher torque requirements. Control and drive systems for an AC stepping motor include microstepping, drivers, and controllers. Microstepping allows the motor to move in even smaller steps than its inherent step angle by controlling the current through the windings. The driver translates digital commands into the appropriate current levels and patterns required by the motor. The controller sends commands to the driver based on input from sensors or user interfaces. Advantages of an AC stepping motor include precision, simple control, and high reliability. Disadvantages include low top speed, resonance issues, and torque drop-off. In summary, an AC stepping motor converts electrical pulses into discrete mechanical movements through the interaction of its stator and rotor components. Its operational simplicity and precision make it ideal for various control applications despite some limitations in speed and resonance concerns.

How do I maintain my internal rotor motor to ensure its longevity ?

Maintaining an Internal Rotor Motor for Longevity involves regular cleaning, inspection, lubrication, and checks on critical components. Proper care can extend the motor's lifespan and prevent costly repairs. Cleaning includes removing dust and debris with a soft cloth and compressed air. Deep cleaning is recommended when there are signs of overheating or reduced performance. Inspections should check for visible damage, wear, insulation resistance, and tight connections. Lubricating moving parts and changing lubricants as needed is essential. Bearings should be checked for wear and replaced if necessary, while cooling systems should be inspected for blockages or leaks. Seal integrity should also be verified. Performance testing and preventive replacement of worn parts can save time and money in the long run. Environmental considerations such as keeping the motor in a clean, dry, and temperate environment should also be taken into account. By following these steps, optimal performance and longevity of the internal rotor motor can be ensured.

In what applications are internal rotor motors commonly used ?

Internal rotor motors, also known as rotary motors or simply electric motors, are widely used in various applications due to their ability to convert electrical energy into mechanical energy. These motors consist of a stationary component (stator) and a rotating component (rotor), which is located inside the stator. The rotor is driven by electromagnetic forces generated by the interaction between the stator and rotor windings. In conclusion, internal rotor motors play a crucial role across numerous sectors, from industrial manufacturing to domestic appliances and even critical medical equipment. Their versatility makes them an essential component in modern technology advancements.

What are the different types of electromagnetic motors ?

This article discusses the various types of electromagnetic motors, including DC motors (brushed and brushless), AC motors (induction and synchronous), stepper motors (bipolar and unipolar), and servo motors (DC and AC). Each type of motor has unique features and applications, such as power demand, speed range, accuracy, and cost. The choice of motor depends on the specific requirements of the application.

What are the different types of fire extinguishers ?

This text provides a comprehensive guide to the various types of fire extinguishers available, each designed for specific classes of fire. It includes detailed descriptions and pros & cons of water, foam, carbon dioxide (CO2), dry chemical, wet chemical, pre-action wet chemical, and clean agent fire extinguishers, emphasizing their suitability for different types of fires such as class A, B, C, and K. The text concludes by highlighting the importance of choosing the right type of extinguisher based on potential fire hazards in one's environment.

What are the different types of preschool programs available ?

Preschool programs are designed to prepare young children for kindergarten and beyond. There are several types of preschool programs available, each with its own unique approach and focus. The most common types of preschool programs include Montessori, Waldorf, Reggio Emilia, High Scope, Play-Based, Head Start, and Co-op/Parent Participation. Each program has its own key features and benefits. When choosing a preschool program for your child, it's essential to consider your family's needs, values, and preferences to find the best fit for your little one's early education journey.

What are the typical故障 of an internal rotor motor, and how can they be fixed ?

Overheating, bearing failure, electrical problems, mechanical wear and tear, and improper installation are common issues with internal rotor motors. Fixes include ensuring proper ventilation and lubrication, replacing worn parts, seeking professional assistance for electrical and installation issues, and regular maintenance to prevent premature failure.

Are there any special safety precautions I should take when working with an internal rotor motor ?

The text discusses safety precautions for working with internal rotor motors. The key points include wearing appropriate personal protective equipment (PPE), disconnecting the power source before starting work, using insulated tools and gloves when working with live electrical components, using proper lifting techniques and equipment when moving heavy motors or components, avoiding contact with moving parts while the motor is running, handling lubricants or coolants carefully to avoid spills or skin contact, storing chemicals in a well-ventilated area away from heat sources and ignition sources, following proper disposal procedures for waste materials generated during maintenance or repair work, working in a well-ventilated area to minimize exposure to fumes or dust, using vacuum cleaners or other collection devices to capture debris and minimize cleanup time, and disposing of hazardous waste materials according to local regulations and guidelines.

Can you explain the different types of PPE and their uses ?

Personal Protective Equipment (PPE) is a type of equipment worn to minimize the risk of injury or illness in the workplace. It can be categorized into different types based on the level of protection they offer and the specific hazards they are designed to protect against. Here are some common types of PPE and their uses: - Head Protection: Hard Hats, Safety Goggles, Face Shields - Respiratory Protection: Dust Masks, Respirators - Hand Protection: Gloves, Mittens - Foot Protection: Safety Shoes, Boots - Body Protection: Aprons, Coveralls, High-Visibility Clothing - Hearing Protection: Earplugs, Earmuffs

Are hub motors more expensive than other types of motors ?

Hub motors are generally more expensive than other types of motors, such as brushed DC motors and induction motors. However, they offer several advantages over these motor types, including their compact size, high efficiency, and low maintenance requirements. Brushless DC motors are generally less expensive than hub motors but still offer many of the same benefits. The choice between these motor types will depend on the specific needs and budget of the vehicle manufacturer or end-user.

What are the main advantages of permanent magnet motors over other types of electric motors ?

Permanent magnet motors (PMMs) have several advantages over other types of electric motors, including high efficiency, low maintenance requirements, high torque density, wide speed range, and quiet operation. These advantages make PMMs ideal for a variety of applications, from small appliances to industrial machinery.

What kind of seasonings work well with different types of fish ?

This text provides a comprehensive guide to seasonings for various types of fish and shellfish, categorized by freshwater and saltwater species. It offers specific seasoning suggestions for each type of fish or shellfish, such as salmon, trout, catfish, tuna, mahi-mahi, sardines, anchovies, shrimp, lobster, crab, clams, mussels, and oysters. The suggested seasonings aim to enhance the natural flavors of the seafood while adding depth and complexity to the dishes.

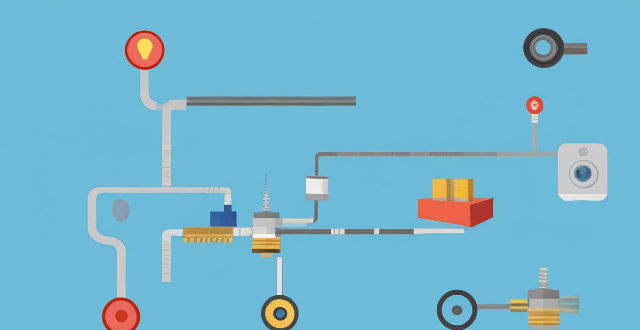

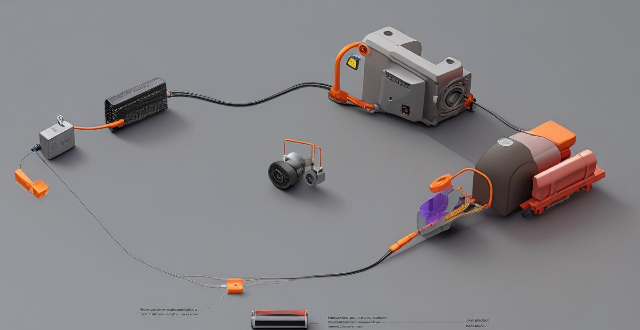

How does an electromagnetic motor work ?

The article provides a comprehensive overview of how an electromagnetic motor works, including its basic components such as the stator, rotor, bearings, commutator (in DC motors), and armature (in AC motors). It explains the operating principles in four steps: applying electrical energy to create a magnetic field around the stator coils, the interaction between the magnetic fields of the stator and rotor causing the Lorentz force, the rotation of the rotor as it tries to align its magnetic poles with those of the stator, and maintaining consistent rotation through current reversal by the commutator in DC motors or changing polarity in AC motors. The article also discusses different types of electromagnetic motors like DC motors, AC motors, stepper motors, synchronous motors, and induction motors, highlighting their unique characteristics and suitability for various applications based on efficiency, power requirements, and control complexity.

Can you provide examples of different types of ecosystem services ?

The text provides a detailed summary of the four main types of ecosystem services, namely supporting, regulating, provisioning, and cultural services. Supporting services form the foundation for all other services and include nutrient cycling, soil formation, and primary production. Regulating services control ecological processes such as climate regulation, disease regulation, and water purification. Provisioning services provide direct material benefits to humans, including food, freshwater, timber, and medicine. Cultural services encompass non-material benefits that contribute to human well-being, such as recreation, spiritual enrichment, and educational opportunities. The text emphasizes the importance of understanding these different types of ecosystem services to appreciate the value of nature and the significance of conservation efforts.

What is an electromagnetic motor ?

Electromagnetic motors are electric motors that use electromagnetic force to convert electrical energy into mechanical energy. They consist of a stator (stationary part) and a rotor (rotating part), along with components like a commutator, brushes, and an armature. The operation involves generating magnetic fields, current flow in rotor coils, interaction between these fields, continuous rotation facilitated by the commutator, and mechanical output through the shaft. Types include DC motors, AC motors, stepper motors, and universal motors, each suitable for different applications.

Should governments prioritize environmental subsidy policies over other types of subsidies ?

The text discusses the pros and cons of prioritizing environmental subsidy policies over other types of subsidies, such as healthcare or education. The author argues that while environmental subsidies can help promote sustainable practices and reduce the negative impacts of human activities on the planet, other types of subsidies are also crucial for the well-being of society. The author suggests a balanced approach that considers both environmental sustainability and social welfare, including integrated policy making, targeted subsidies, public-private partnerships, and continuous evaluation.

What are some common types of emergencies and how should they be handled ?

Emergencies can occur at any time and place, often without warning. Knowing the types of emergencies and how to handle them is crucial for ensuring safety and minimizing harm. In this article, we will discuss some common types of emergencies and their appropriate handling methods. ## Natural Disasters Natural disasters are events caused by environmental factors that result in widespread damage and loss of life. Some common types of natural disasters include earthquakes, hurricanes, floods, wildfires, and tornadoes. When faced with a natural disaster, it is essential to stay calm, seek shelter, follow evacuation orders, have an emergency kit ready, and stay informed about the situation. ## Medical Emergencies Medical emergencies refer to situations where immediate medical attention is required to prevent serious harm or death. Some common types of medical emergencies include heart attacks, strokes, severe allergic reactions, severe bleeding, and choking. When dealing with a medical emergency, it is crucial to call for help, perform first aid if trained, use automated external defibrillators (AEDs) if available, do not move the victim unless necessary, and stay with the victim until help arrives. ## Fire Emergencies Fire emergencies involve uncontrolled fires that pose a threat to people and property. Some common types of fire emergencies include house fires, wildfires, car accidents involving fire, and industrial fires. When facing a fire emergency, it is important to activate fire alarms/alert others, evacuate safely through designated exits, call emergency services immediately, do not reenter burning buildings, and use fire extinguishers appropriately if trained and safe to do so. In conclusion, being prepared for emergencies is crucial for ensuring safety and minimizing harm. By understanding common types of emergencies and their appropriate handling methods, individuals can respond effectively in crisis situations. Remember to stay calm, act quickly, and follow proper procedures to protect yourself and others.

What is the current market share of CHEVs compared to other types of green vehicles ?

The market share of CHEVs compared to other types of green vehicles can be broken down into several categories, including hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and battery electric vehicles (BEVs). HEVs are one of the most popular types of green vehicles on the market today, accounting for approximately 2.5 million units sold worldwide in 2020. PHEVs are similar to HEVs but have a larger battery pack that can be charged from an external power source, with global sales reaching around 1.3 million units in 2020. BEVs are fully electric vehicles that rely solely on batteries for power, with global sales reaching over 3 million units in 2020. When comparing CHEVs to other types of green vehicles, it is important to note that CHEVs fall under the category of HEVs. Therefore, the actual market share of CHEVs compared to other types of green vehicles would likely be much smaller than 2.5 million units sold worldwide in 2020.

How do permanent magnet motors work, and what makes them more efficient ?

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

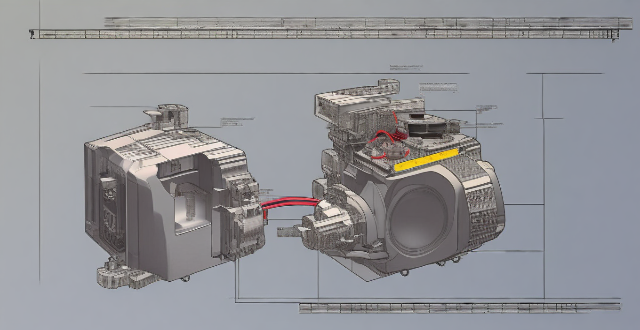

How is an electromagnetic motor designed and constructed ?

Design and construction of an electromagnetic motor involves selecting appropriate components, determining specifications, choosing the type of motor, designing the stator and rotor, calculating winding patterns, assembling the motor, installing a commutator if applicable, connecting wiring and control electronics, testing and troubleshooting, and finalizing and optimizing the design. The key components include the stator, rotor, bearings, commutator, and armature. The steps ensure that the motor meets the required specifications and operates efficiently for its intended use.

Are permanent magnet motors more susceptible to damage from high temperatures compared to other motor types ?

Permanent magnet motors are more susceptible to high temperatures due to demagnetization and thermal expansion issues, compared to induction motors and switched reluctance motors which primarily face insulation degradation and material fatigue respectively.

How do celebrity mansions compare to other types of luxury real estate, such as penthouse apartments or beachfront properties ?

Celebrity mansions are often compared to other types of luxury real estate, such as penthouse apartments or beachfront properties. While all these properties share some common features, there are also significant differences between them. In this article, we will explore the similarities and differences between celebrity mansions and other types of luxury real estate.

What are the different types of radiation and how do they differ in terms of risk ?

This text discusses two main types of radiation: ionizing and non-ionizing, detailing their characteristics, examples, and potential risks. Ionizing radiation, which includes alpha particles, beta particles, gamma rays, X-rays, and neutrons, can damage living tissue and DNA, leading to cancer and other health issues. Non-ionizing radiation, such as ultraviolet light, visible light, microwaves, radio waves, and extremely low-frequency radiation (ELF), generally poses lower risks but can still cause harm with high levels of exposure. The text emphasizes the importance of managing exposure to both types of radiation to mitigate potential risks.

What is the efficiency of an electromagnetic motor compared to other types of motors ?

This article compares the efficiency of an electromagnetic motor with other types of motors such as DC motors, AC motors, stepper motors, and servo motors. Electromagnetic motors have a high efficiency rate, typically ranging from 80% to 95%, making them suitable for applications where energy consumption is a concern. DC motors have lower efficiency rates, typically around 50% to 70%, while AC motors have higher efficiency rates, up to 95% or more, but are generally less efficient than electromagnetic motors due to losses in the windings and core. Stepper motors have relatively low efficiency rates compared to other types of motors, typically around 30% to 50%, while servo motors have moderate efficiency rates, typically around 60% to 80%. Overall, the choice of motor depends on various factors such as cost, size, weight, and required performance characteristics.