Standards Industrial

How do international standards and certifications affect industrial energy efficiency practices ?

International standards and certifications significantly influence industrial energy efficiency practices by setting uniform benchmarks, driving innovation, enhancing reputation, promoting transparency, supporting regulatory compliance, and leveraging resource efficiency. These standards provide a framework for continuous improvement, drive technological advancements, expand market opportunities, ensure accountability, align with policies, reduce waste, and offer cost benefits. As sustainability becomes a global priority, adherence to these standards will be crucial for industrial competitiveness and success.

What are the OSHA standards for electrical safety in the workplace ?

OSHA has established standards for electrical safety in the workplace to protect employees from hazards associated with electricity. These standards cover training, lockout/tagout procedures, arc flash hazard protection, grounding and bonding, and maintenance of electrical wiring and equipment. Specific requirements vary depending on the type of workplace, such as construction sites, industrial settings, and office environments. By following these standards and implementing appropriate controls, employers can create a safe work environment and reduce the risk of electrical accidents and injuries.

How do wireless communication standards work ?

Wireless communication standards are essential for enabling seamless interactions between devices, and they operate within specific guidelines and protocols. These standards cover areas such as frequency bands, modulation techniques, multiple access methods, error handling, security measures, and compliance testing to ensure interoperability among various devices. Understanding these components is key to grasping how wireless technologies work together to create our interconnected world.

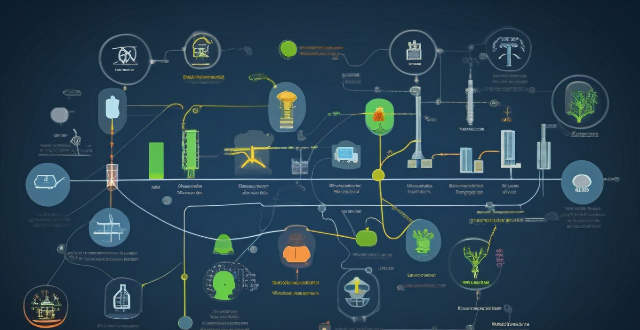

What are some innovative methods for improving industrial energy efficiency ?

Innovative Methods for Improving Industrial Energy Efficiency - Advanced Technologies: AI and Machine Learning for predictive maintenance and optimization of energy consumption, IoT sensor networks and remote control systems. - Process Optimization Techniques: Heat Recovery Systems like energy recuperation and Combined Heat and Power (CHP), process integration through industrial symbiosis and lean manufacturing. - Building Design and Management: Green architecture using eco-friendly materials and natural lighting/ventilation, Smart Building Management Systems with automated controls and energy management software. - Employee Training and Involvement: Educational programs on energy conservation, skill development for new technologies, participation incentives through reward systems and team challenges.

Is there a difference between PPE for medical use versus industrial use ?

The text discusses the differences between personal protective equipment (PPE) for medical use and industrial use. It explains that these differences mainly concern the level of protection required, the type of hazards encountered, and the specific features of the equipment designed to address those hazards. Medical professionals often deal with infectious diseases and thus require PPE that can protect them from pathogens like viruses and bacteria. This typically involves higher levels of protection, such as respiratory protection with N95 respirators or equivalent, which filter out airborne particles, and blood-borne pathogen protection with gloves, gowns, and face shields or goggles to prevent contact with blood and bodily fluids. Industrial workers face different types of hazards, including chemical exposure, physical injuries, and environmental factors. Their PPE tends to focus on chemical protection with protective suits, gloves, and boots made from materials resistant to specific chemicals or solvents, and physical protection with hard hats, safety glasses, and high-visibility clothing to prevent injuries from machinery or construction sites. The primary hazard in a medical setting is biological agents, such as viruses, bacteria, and other pathogens that may be present in patients' blood or other bodily fluids. Workers in industrial settings face a variety of hazards, including but not limited to chemical exposure from handling toxic substances, physical dangers from heavy machinery and equipment operation, and environmental risks such as extreme temperatures or noise pollution. PPE for medical use often includes features like fluid resistance with materials that are impermeable to liquids to prevent contamination, antimicrobial treatment with some PPE items having an antimicrobial coating to reduce the growth of microorganisms, and compatibility with other medical equipment designed to be used in conjunction with other medical tools and devices without interference. PPE for industrial use emphasizes features like durability with materials that can withstand harsh conditions and repeated use, comfort and mobility often lighter and more flexible materials to allow for ease of movement over long periods, and specialized functionality such as gloves having enhanced grip or shoes having steel toes for added protection against physical impacts.

How can businesses implement energy-saving technologies in their industrial processes ?

Businesses can implement energy-saving technologies in their industrial processes by conducting an energy audit, identifying opportunities for savings, developing an energy management plan, investing in energy-efficient equipment, optimizing processes, training employees on energy-saving practices, and regularly monitoring performance.

How do wireless communication standards affect mobile devices ?

Wireless communication standards significantly impact mobile devices' performance, functionality, and user experience. They influence speed and bandwidth, latency, connectivity range, compatibility with different networks, interoperability, security features, battery life, quality of service, mobility and portability, and device form factors. Advances in these standards drive innovation in the mobile industry, leading to faster, more reliable devices offering richer experiences to consumers.

What are the consequences of ignoring safety standards in construction work ?

Ignoring safety standards in construction work can lead to severe consequences, including risk to human life, project delays, financial losses, reputation damage, legal implications, environmental impact, and public safety concerns. Adhering to these standards is crucial for the well-being of all involved parties and the success of the project.

In what scenarios is it necessary to use chemical protective measures in an industrial setting ?

Industrial settings often require chemical protective measures to ensure worker safety. These scenarios include handling hazardous chemicals, working in confined spaces, performing maintenance on chemical process equipment, disposing of hazardous waste, and emergency response to chemical incidents. Workers must wear appropriate personal protective equipment (PPE) such as gloves, aprons, goggles, and respiratory protection devices to prevent exposure to harmful chemicals. Examples of these scenarios include manufacturing processes involving strong acids or bases, tank cleaning in the petrochemical industry, repairing valves or pipes in chemical processing plants, disposal of chemical waste at landfill sites, and firefighting and rescue operations during chemical fires or explosions. By implementing these chemical protective measures in relevant industrial scenarios, employers can help safeguard their employees from potential health hazards associated with chemical exposure.

How do ESG standards affect corporate responsibility ?

ESG standards shape corporate responsibility by providing a framework for measuring and managing company impact on the environment, society, and governance. They require companies to reduce their carbon footprint, ensure sustainable sourcing, promote diversity and inclusion, engage with communities, maintain ethical business practices, and encourage board diversity. Adhering to these standards demonstrates commitment to sustainability and social responsibility, leading to long-term success and profitability.

How do building energy efficiency standards vary across different countries ?

The article discusses building energy efficiency standards and their global variations, influenced by factors like climate, economics, technology, government policies, and cultural preferences. It highlights the importance of these standards in sustainable development and reducing carbon emissions in the built environment. The text emphasizes that understanding these variations is essential for collaborative efforts and knowledge sharing as the global community strives towards decarbonization and sustainability goals.

How do building energy efficiency standards impact the environment ?

**Summary:** Building energy efficiency standards positively impact the environment by reducing greenhouse gas emissions, conserving natural resources, enhancing air quality, and promoting energy innovation. These standards lead to more energy-efficient buildings, reduced dependence on fossil fuels, cleaner air, and advancements in sustainable technologies.

How do celebrities influence fashion trends and beauty standards ?

Celebrities significantly influence fashion trends and beauty standards through their endorsements, red carpet appearances, social media presence, and collaborations with designers. They set trends by making innovative style choices and promoting self-care and wellness. However, their influence is not without controversy, as some argue it leads to unrealistic beauty standards and cultural appropriation.

What role does government policy play in promoting industrial energy efficiency ?

Government policies significantly influence industrial energy efficiency through regulation, financial incentives, research support, public awareness, green procurement, and international cooperation. These measures help set standards, drive innovation, and create a conducive environment for the adoption of efficient practices, ultimately contributing to economic growth with minimal environmental impact.

How have building energy efficiency standards evolved over time ?

The evolution of building energy efficiency standards has been significant over the years, with a focus on reducing energy consumption and environmental impact. Early beginnings saw little consideration for energy consumption, leading to high utility bills and greenhouse gas emissions. The rise of energy conservation in the 1970s led to the development of the first building energy efficiency standards, focusing on measures such as improved insulation and efficient heating and cooling systems. The advent of green buildings in the 1990s brought new standards that minimized environmental impact through the use of renewable energy sources and sustainable materials. Technology has played a significant role in improving energy efficiency, with advances such as smart thermostats and LED lighting. Looking to the future, there is likely to be a greater emphasis on reducing energy consumption in buildings, leading to stricter standards and the development of new technologies. Overall, building energy efficiency standards have evolved to become an essential part of modern building design and construction.

Are there any international standards for carbon credit systems ?

There are several international standards and protocols that govern carbon credit systems, including the Climate Action Reserve (CAR), the International Carbon Reduction and Offset Alliance (ICROA), and regional and national standards such as the European Union Emissions Trading System (EU ETS) and the North American Carbon Programme (NACP). These standards ensure the credibility, transparency, and integrity of carbon offset projects by setting rigorous guidelines for project developers to follow. By adhering to these standards, organizations can demonstrate their commitment to combating climate change and contribute to a more sustainable future.

What are the current building energy efficiency standards ?

The text discusses building energy efficiency standards, which are regulations and guidelines designed to reduce energy consumption. These standards promote sustainable development, reduce greenhouse gas emissions, and improve indoor air quality. The text lists seven key areas for improving energy efficiency: insulation and air tightness, heating, ventilation, and air conditioning systems, lighting systems, renewable energy sources, water efficiency, building materials and construction practices, and energy management and monitoring. Each area includes specific strategies and technologies that can be employed to increase energy efficiency.

How do building energy efficiency standards affect the construction industry ?

Building energy efficiency standards have a significant impact on the construction industry by affecting cost implications, design philosophy, regulatory compliance, and market trends. These standards require higher initial costs due to advanced technologies and materials but offer long-term benefits like reduced energy consumption and maintenance costs. They also shift the focus of design towards energy performance and sustainability, leading to integrated design processes and innovative solutions. Compliance with these standards is crucial to avoid penalties and legal issues, while certifications like LEED or WELL can provide a competitive advantage. Finally, building energy efficiency standards influence market trends by driving demand for sustainable construction methods and educating clients about their benefits.

What are the potential consequences of ignoring food safety standards ?

Ignoring food safety standards can lead to health risks, legal issues, and damage to a company's reputation. The most immediate consequence is potential harm to human health, including foodborne illnesses, allergic reactions, and chronic health problems. Legal issues may arise from fines and penalties, lawsuits, and loss of business licenses. Ignoring food safety standards can also damage a company's reputation through loss of customer trust, negative publicity, and decreased sales. It is essential for all stakeholders in the food industry to prioritize food safety practices to protect public health, comply with legal requirements, and maintain a positive reputation.

How do global ESG standards vary across different industries ?

Global Environmental, Social and Governance (ESG) standards are used by organizations to measure and manage their impact on the environment, society, and governance. These standards vary across different industries due to the unique challenges and opportunities each industry presents. In the energy industry, ESG standards focus on reducing greenhouse gas emissions, improving air quality, and promoting renewable energy sources. The financial services industry faces unique ESG challenges related to responsible investment, diversity and inclusion, and ethical business practices. Manufacturing companies face ESG challenges related to waste reduction, worker safety, and supply chain management. The healthcare industry faces unique ESG challenges related to patient safety, data privacy, and access to affordable healthcare. The technology industry faces ESG challenges related to digital security, privacy protection, and responsible innovation. By focusing on specific areas of concern within each industry, organizations can work towards creating a more sustainable future while also improving their overall performance and reputation.

What are the most effective methods for improving industrial energy efficiency ?

The most effective methods for improving industrial energy efficiency include process optimization, using energy-efficient equipment, harnessing renewable energy sources, thermal management, power management, employee training and awareness, employing energy information systems, and complying with policy and regulatory standards. These methods can reduce operational costs, conserve resources, and minimize environmental impact.

What are the latest wireless communication standards ?

This article discusses the latest wireless communication standards, including 5G, Wi-Fi 6, Bluetooth 5.2, and LoRaWAN. It highlights their key features, such as enhanced mobile broadband for 5G, OFDMA and MU-MIMO for Wi-Fi 6, LE Audio and direction finding for Bluetooth 5.2, and long range and low power consumption for LoRaWAN. The article also mentions potential use cases for each standard, such as smart cities and autonomous vehicles for 5G, home networks and public Wi-Fi hotspots for Wi-Fi 6, personal audio devices and wearable technology for Bluetooth 5.2, and smart agriculture and environmental monitoring for LoRaWAN.

What is the cost of meeting building energy efficiency standards for homeowners and builders ?

Meeting building energy efficiency standards is crucial for reducing energy consumption and promoting sustainability, but it comes with certain costs that both homeowners and builders need to consider. The initial investment includes design and planning fees, high-performance windows and doors, insulation, energy-efficient appliances, skilled tradespeople, and additional time. Ongoing maintenance and operation costs include utility bills, potential tax credits and rebates, regular inspections, repairs, and replacements. Despite the costs, meeting these standards offers benefits such as reduced carbon footprint, improved air quality, health and comfort, lower utility bills, and increased property value.

How can architects and designers incorporate building energy efficiency standards into their work ?

Incorporating Building Energy Efficiency Standards into Architectural and Design Work: - Understanding Energy Efficiency Standards: Research current standards, analyze local climate data. - Design Strategies for Energy Efficiency: Orientation and site layout, insulation and envelope performance, HVAC, lighting and electrical systems, water efficiency. - Material Selection: Sustainable materials, recycled content. - Technology Integration: Building automation systems, solar technology. - Collaboration and Communication: Team collaboration, client education. - Post-Occupancy Evaluation: Monitor performance, feedback loop.

How can I ensure that my sports facility is compliant with all relevant regulations and standards ?

To ensure your sports facility's compliance with all relevant regulations and standards, you should research and understand the applicable rules, conduct a compliance audit, develop a plan to address any non-compliant areas, train your staff, and maintain compliance over time.

What are the most effective ways to measure compliance with building energy efficiency standards ?

The topic summary for the text is "Measuring Compliance with Building Energy Efficiency Standards". The text discusses various methods used to assess a building's energy efficiency, including energy audits, building performance monitoring, third-party verification, benchmarking, energy efficiency ratings, and regulatory compliance checklists. Each method has its own advantages and can be used in combination to ensure that buildings meet minimum requirements for energy efficiency and contribute to reducing their environmental impact.

How can students with English as a second language be supported in understanding and applying academic integrity standards ?

The text discusses the importance of supporting students with English as a second language (ESL) in understanding and applying academic integrity standards. It outlines four key strategies for doing so: providing clear explanations, accessible resources, open communication, and extra support. Clear explanations should cover what constitutes academic dishonesty, the consequences of violations, and how to avoid dishonesty. Accessible resources such as glossaries, guides, and videos can help ESL students understand these concepts better. Encouraging open communication between students and instructors can address concerns and questions about academic integrity. Providing extra support through tutoring services, workshops, and peer mentoring programs can further assist ESL students in adhering to academic integrity standards.

How do industrial processes contribute to greenhouse gas emissions ?

Industrial processes significantly contribute to greenhouse gas (GHG) emissions, which are a major driver of climate change. These contributions come from various sources including energy consumption, manufacturing processes, agricultural industries, construction industries, and waste management. Mitigation strategies such as improving energy efficiency, optimizing processes, implementing carbon capture and storage technologies, and enforcing policy and regulation can help reduce these emissions.

What are the economic benefits of investing in energy-efficient industrial equipment ?

Investing in energy-efficient industrial equipment can lead to reduced energy costs, increased production efficiency, potential tax incentives and grants, enhanced competitiveness, improved environmental sustainability, and greater long-term asset value. These benefits make such investments financially prudent and strategically sound for businesses looking to remain competitive and responsible in today's market.

How do industrial activities influence climate change ?

Industrial activities significantly impact climate change by emitting greenhouse gases like CO2, CH4, and N2O, contributing to deforestation, relying on fossil fuels for energy, and producing waste. These activities also affect transportation and logistics, leading to further emissions. While some industrial processes release cooling aerosols, they cause other environmental issues. Technological advancements and policy regulations aim to mitigate these impacts by promoting renewable energy, efficiency improvements, and carbon capture.