Wind Magnet

Can permanent magnet motors be used in renewable energy systems such as wind turbines ?

Permanent magnet motors are used in renewable energy systems, including wind turbines, due to their high efficiency and reliability. They offer advantages such as high efficiency, low maintenance, good torque characteristics, size and weight benefits, and adaptability. However, challenges and considerations include cost, thermal management, and dependence on rare earth metals. Overall, permanent magnet motors are a popular choice for efficient and reliable energy conversion in wind power applications.

What is the role of neodymium in the production of high-performance permanent magnet motors ?

Neodymium is crucial for making high-performance permanent magnet motors. It increases efficiency, power density, and thermal stability while reducing costs and maintenance. These motors are used in various applications like electric vehicles and aerospace systems.

In which industries are permanent magnet motors most commonly used ?

Permanent magnet motors are utilized across a wide range of industries due to their efficiency and reliability. Key sectors include the automotive industry, where they power electric and hybrid vehicles and are used in automated manufacturing. In aerospace and defense, PM motors are crucial for aircraft systems and military applications. Appliance manufacturing benefits from PM motors in household and commercial equipment. The medical sector employs them in imaging equipment and surgical tools. Manufacturing and process control use PM motors in CNC machinery and pumps/valves. Renewable energy sectors such as wind turbines and solar tracking systems also rely on these motors. Consumer electronics, including audio and visual equipment as well as toys and hobbyist products, make use of permanent magnet motors for various functions.

Is it possible to recycle the magnets used in permanent magnet motors at the end of their life cycle ?

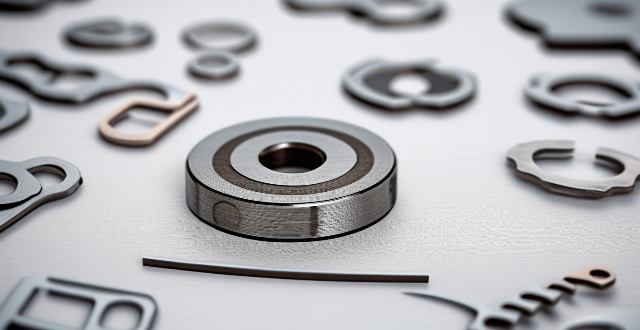

Permanent magnet motors are widely used in various applications, including electric vehicles, wind turbines, and industrial machinery. However, these motors rely on strong permanent magnets to generate torque and convert electrical energy into mechanical energy. As with any technology, these magnets have a limited lifespan and will eventually need to be replaced or recycled. In this article, we will explore the feasibility of recycling permanent magnets used in motors at the end of their life cycle. One of the main challenges in recycling permanent magnets is that they often contain harmful materials such as neodymium (Nd), dysprosium (Dy), and boron (B). These elements are toxic and require special handling during the recycling process to prevent environmental contamination. Additionally, the extraction and refining processes for these elements can be energy-intensive and costly. Another challenge is the complexity of the recycling process itself. Permanent magnets are typically made up of multiple layers of different materials, including iron, copper, aluminum, and rare earth metals. Separating these materials requires specialized equipment and techniques, which can be expensive and time-consuming. Furthermore, the quality of recycled magnets may not be as high as that of newly manufactured magnets, potentially limiting their usefulness in certain applications. Despite the challenges mentioned above, recycling permanent magnets has several potential benefits. One significant advantage is the conservation of rare earth metals, which are essential components of many modern technologies but are also relatively scarce resources. By recovering these metals from discarded magnets, we can reduce our reliance on new mining operations and help ensure a more sustainable supply chain for critical technologies. Recycling permanent magnets can also lead to cost savings and improved energy efficiency. By reusing materials that would otherwise be discarded, we can reduce waste and lower production costs for new magnets. Additionally, since the recycling process itself requires less energy than extracting and refining raw materials from scratch, it can contribute to overall energy savings and reduced greenhouse gas emissions. There are several methods for recycling permanent magnets, including mechanical separation, chemical extraction, and hydrometallurgical processing. Mechanical separation involves breaking down the magnet into its constituent parts using various tools and machines, such as hammers, grinders, and magnetic separators. Chemical extraction involves dissolving the magnet in acid or other solvents to separate the rare earth metals from other materials. Hydrometallurgical processing involves using water-based solutions to leach out the rare earth metals from the magnet material. While each method has its advantages and disadvantages, all three require specialized equipment and expertise to ensure safe and efficient operations. In conclusion, while there are certainly challenges associated with recycling permanent magnets used in motors at the end of their life cycle, there are also significant potential benefits. By conserving rare earth metals, reducing waste, and improving energy efficiency, we can help create a more sustainable future for critical technologies like permanent magnet motors. With continued research and development in recycling techniques and processes, we can hope to overcome the current challenges and make recycling permanent magnets a viable option for extending their useful lifespan and minimizing environmental impact.

How does the design of a permanent magnet motor differ from an induction motor ?

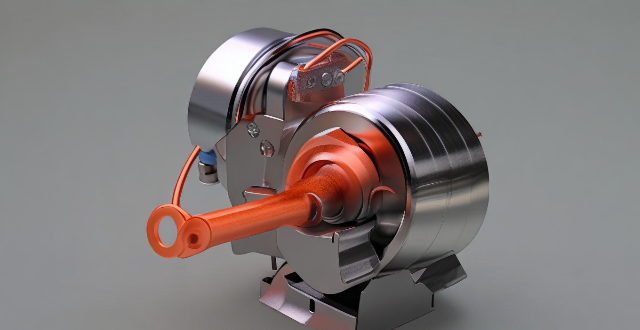

The article discusses the differences between permanent magnet motor and induction motor design, focusing on three main aspects: rotor design, stator winding design, and cooling system. The rotor of a permanent magnet motor contains high-energy rare-earth magnets that interact with the stator windings to produce torque, while the rotor of an induction motor has aluminum or copper bars that induce currents when exposed to a rotating magnetic field produced by the stator windings. The stator winding design also varies between the two types of motors, with permanent magnet motors typically having a three-phase distributed winding and induction motors having either a distributed or concentrated winding. Finally, the cooling system design differs as well, with permanent magnet motors often relying on natural convection or forced air cooling, while induction motors may use external fans or blowers for more effective heat removal. Understanding these differences is crucial for engineers to choose the appropriate motor type for their needs and optimize its performance accordingly.

How do you maintain and care for a permanent magnet motor to extend its lifespan ?

Permanent magnet motors are widely used in various industries due to their high efficiency, power density, and reliability. However, proper maintenance and care are essential to extend the lifespan of these motors. Here are some tips on how to maintain and care for a permanent magnet motor: - Regular cleaning, lubrication, thermal management, electrical maintenance, mechanical maintenance, environmental considerations, and preventive maintenance schedule are all important aspects of maintaining a permanent magnet motor. - External and internal cleaning should be done regularly to keep the motor clean from dust, dirt, and debris. Lubrication of bearings and gearbox (if any) should be done according to the manufacturer's recommendations. - Thermal management includes ensuring that the cooling system is functioning properly and monitoring the temperature of the motor during operation. Overheating can cause damage to the magnets and other components. - Electrical maintenance involves checking all electrical connections periodically to ensure they are secure and free from corrosion. Insulation resistance should also be tested periodically to detect any potential issues before they become serious problems. - Mechanical maintenance includes ensuring that the motor shaft is properly aligned with the load and performing vibration analysis periodically to identify any mechanical issues such as imbalance or loose parts. - Environmental considerations involve storing and operating the motor in a dry environment to prevent rust and corrosion. Protection from harsh environmental conditions such as extreme temperatures, chemicals, or moisture should also be considered. - A preventive maintenance schedule should be created based on the manufacturer's recommendations and specific application requirements. Regular inspections and prompt attention to any issues will save time and money in the long run by preventing more significant problems from occurring.

What is offshore wind energy and how does it work ?

Offshore wind energy is a renewable source that generates electricity from wind turbines installed in bodies of water. It offers advantages such as higher wind speeds and less impact on terrestrial environments but faces challenges including high installation costs and environmental considerations. The process involves converting wind power into electrical energy, which is then transmitted to the mainland grid.

Can wind turbines be used in residential areas ?

The use of wind turbines in residential areas is possible and offers numerous benefits, including reduced dependence on fossil fuels and increased energy independence. However, there are challenges such as zoning laws, noise levels, and aesthetic concerns that must be considered. Economic factors like upfront costs and maintenance expenses also play a role. To successfully implement wind turbines in residential settings, homeowners should assess their site's suitability, work with professionals to plan the system, engage with the community, choose a reputable installer, and monitor the turbine's performance regularly.

What is the typical cost difference between a permanent magnet motor and an equivalent size induction motor ?

Permanent magnet motors (PMMs) and induction motors (IMs) are two common types of electric motors used in various applications. The cost difference between them is often a significant factor in deciding which one to use. PMMs are known for their high efficiency, compact size, and low noise levels, while IMs are simpler and more robust. The cost difference depends on factors such as size, power rating, materials used, and manufacturing processes. Generally, PMMs are more expensive than IMs of equivalent size due to material costs, manufacturing processes, efficiency and performance requirements, and market demand and availability. When choosing between these two types of motors, it is essential to consider both the technical requirements and budget constraints of your specific application.

What is wind energy and how does it work ?

Wind energy is a renewable and sustainable source of electricity that harnesses the power of wind through the use of wind turbines. It offers several advantages, including being environmentally friendly, cost-effective, and job-creating. However, challenges such as intermittency, site selection, visual impact, and wildlife impacts must be considered. Despite these challenges, advancements in technology and planning practices are making wind energy an increasingly viable option for meeting our energy needs.

What countries are leading in wind energy production ?

The leading countries in wind energy production are China, the United States, Germany, India, and Spain. China has the largest installed capacity with 282 GW as of 2021, followed by the US with 119 GW, Germany with 60 GW, India with 38 GW, and Spain with 26 GW. These countries have seen rapid growth and innovation in their wind energy sectors, with key regions and states contributing significantly to their overall output. Their efforts demonstrate a commitment to reducing carbon emissions and transitioning towards sustainable energy sources.

How does wind energy affect the environment ?

Wind energy is a renewable source of power that has become increasingly popular as an alternative to fossil fuels. However, like any form of energy production, it does have some environmental impacts. The positive effects of wind energy on the environment include a reduction in greenhouse gas emissions, conservation of natural resources such as water and no need for fuel. Wind farms can coexist with agricultural activities and modern turbine designs can help minimize impacts on local wildlife. However, there are also potential negative effects on the environment. These include visual and noise pollution, as well as potential impacts on wildlife such as bird and bat collisions and habitat disruption. The presence of large structures like wind turbines can also alter local wind patterns and potentially affect microclimates. Overall, while wind energy offers significant benefits in terms of reducing greenhouse gas emissions and conserving natural resources, it is not without its challenges regarding visual and noise pollution, as well as potential impacts on wildlife. Careful planning and technological advancements can help mitigate these negative effects, making wind energy an increasingly viable option for a sustainable future.

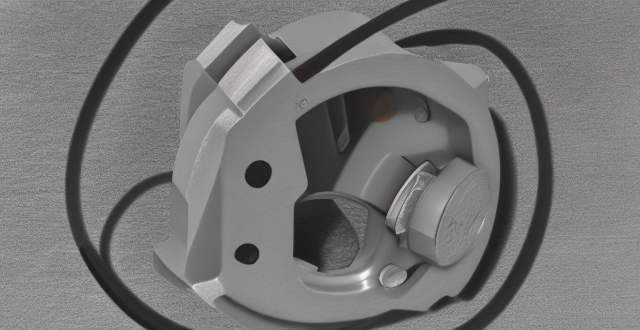

How do permanent magnet motors work, and what makes them more efficient ?

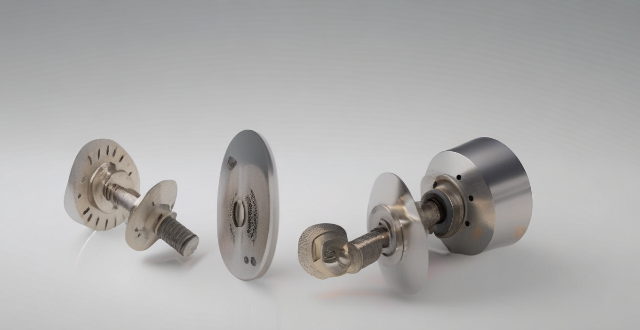

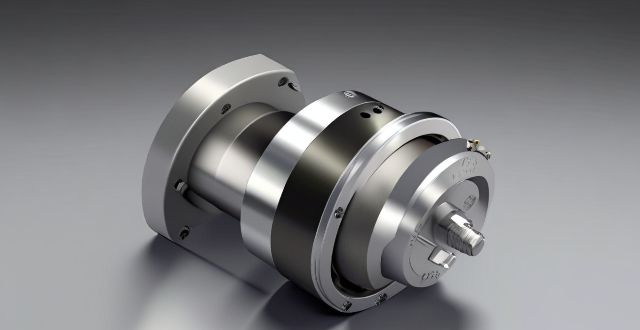

Permanent magnet motors operate on the principle of electromagnetic induction, consisting of a rotor with permanent magnets and a stator with windings. When an electric current is passed through the stator windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing the rotor to rotate and generate mechanical energy. Key components of a permanent magnet motor include the rotor, stator, windings, and magnetic field. The rotor is the rotating part of the motor that contains permanent magnets, while the stator is the stationary part with windings. The windings are conductors wound around the stator through which electric current flows, creating a magnetic field. Permanent magnet motors are known for their high efficiency compared to other types of motors due to several factors. They have a higher power density than conventional motors, meaning they can produce more power per unit volume or weight. This is because they use strong permanent magnets, which create a stronger magnetic field without requiring additional space or materials. Permanent magnet motors also have lower energy losses due to reduced copper losses, iron losses, and friction losses. They can produce a higher torque at lower speeds compared to other motor types, operate efficiently over a wide range of speeds, and perform regenerative braking, where they convert kinetic energy into electrical energy during deceleration. Overall, these advantages make permanent magnet motors well-suited for applications where energy efficiency is a critical factor, such as electric vehicles and industrial equipment.

How can wind energy contribute to a sustainable future ?

Wind energy is a renewable and sustainable source of power that can significantly contribute to a more sustainable future. It offers several benefits including reducing carbon emissions, stimulating economic growth, enhancing energy security, driving technological innovation, compatible land use, community engagement, scalability, improving health impacts, and promoting education and awareness. By incorporating wind energy into our energy mix, we can create a cleaner, healthier, and more sustainable environment for future generations.

What are the current challenges in scaling up wind energy production globally ?

The article discusses the various challenges that need to be addressed in order to scale up wind energy production globally. These include infrastructure development, technological barriers, environmental impact, economic factors, regulatory issues, and social acceptance. Overcoming these obstacles requires collaborative efforts from all stakeholders involved in the wind energy sector.

How can wind energy be stored for later use ?

Storing wind energy is crucial for integrating renewable energy into power grids. Wind turbines produce electricity intermittently based on weather conditions, unlike traditional power plants that can adjust output on demand. Several methods exist to store wind energy effectively, including battery storage systems, pumped hydro storage, compressed air energy storage (CAES), chemical batteries, flow batteries, thermal storage, and flywheels. When selecting a storage method, factors such as capacity, duration, cost, efficiency, environmental impact, and geographic suitability must be considered. As technology advances and costs decrease, we can expect more innovative solutions for efficient wind energy storage.

How does wind energy compare to solar energy ?

Wind energy and solar energy are both renewable sources of energy that have gained popularity in recent years. Wind turbines can generate electricity with high efficiency and low maintenance cost, while solar panels have a low initial cost and long lifespan. However, wind turbines can create noise pollution and have limited availability, while solar panels rely on sunlight and require a large amount of land. Both sources have their advantages and disadvantages, making them suitable for different applications.

Are there any drawbacks to using permanent magnet motors in certain applications ?

The text discusses the drawbacks of using permanent magnet motors in certain applications, including high cost, demagnetization risk, limited speed range, difficulty in controlling torque and speed, and sensitivity to heat and vibration. These factors make them less suitable for applications where cost is a primary concern, precise control is necessary, or exposure to high temperatures or vibrations is common.

How has the development of permanent magnet motor technology evolved over the past decade ?

Over the past decade, permanent magnet motor technology has seen significant advancements due to increased demand for energy-efficient technologies, improvements in materials science, and the growing need for sustainable transportation solutions. Key developments include improved materials like NdFeB and SmCo, advanced manufacturing techniques, innovative designs such as axial flux motors and spoke-type rotor designs, widespread adoption in electric vehicles, and use in energy-efficient applications. Looking ahead, permanent magnet motor technology will continue to evolve and play a vital role in creating more sustainable and energy-efficient systems.

Is wind energy a viable option for developing countries ?

Is wind energy a viable option for developing countries? Yes, wind energy offers numerous benefits such as cost-effectiveness, sustainability, job creation, and improved energy security. However, several challenges must be addressed including infrastructure needs, financing barriers, policy development, and environmental considerations. With careful planning and strategic investments, wind energy can indeed be a viable option for developing countries looking to build a sustainable future.

How efficient is wind energy compared to other renewable sources ?

The efficiency of wind energy is influenced by factors such as capacity factor, technological advancements, and site specificity. Compared to other renewable sources like solar, hydropower, geothermal, biomass, and tidal/wave energy, wind energy has a relatively high capacity factor ranging from 35% to 45%. Technological improvements have increased the efficiency of wind turbines over the years, making them more productive. However, the efficiency of wind farms is highly dependent on the location, with optimal sites achieving higher efficiency rates. In conclusion, wind energy compares favorably to other renewable sources in terms of efficiency, but the choice between different renewable energies often depends on local conditions, economic factors, and technological advancements.

How much does it cost to install a wind turbine ?

Installing a wind turbine can be a significant investment, and the cost varies depending on several factors such as the size of the turbine, location, and installation complexity. Here is a detailed breakdown of the costs involved in installing a wind turbine: 1. **Turbine Cost**: Small Turbines typically used for residential purposes can cost anywhere between $30,000 to $50,000. Large Turbines used for commercial purposes can cost upwards of $1 million. 2. **Site Assessment and Permitting**: Site Assessment involves evaluating the site for wind speed, topography, and other factors that affect the performance of the turbine. The cost can range from $5,000 to $15,000. Depending on the local regulations, obtaining necessary permits can cost between $5,000 to $20,000. 3. **Foundation and Construction**: The foundation needs to be strong enough to support the turbine, and the cost can vary between $10,000 to $30,000. The actual installation of the turbine can cost between $6,000 to $12,000. 4. **Electrical Connections and Grid Interconnection**: This includes setting up the wiring and electrical connections needed to connect the turbine to your home or business. The cost can range from $8,000 to $15,000. If you plan to sell excess electricity back to the grid, you will need to set up a grid interconnection. This can cost between $5,000 to $10,000. 5. **Maintenance and Operational Costs**: Regular maintenance is required to ensure the turbine operates efficiently and safely. Annual maintenance costs can range from $1,000 to $3,000. This includes costs associated with operating the turbine, such as insurance and taxes. The cost can vary depending on the location and size of the turbine. 6. **Total Cost**: The total cost of installing a wind turbine can range from $75,000 to $1.5 million or more, depending on the size and complexity of the project. It is important to consider these costs before deciding to install a wind turbine. In conclusion, installing a wind turbine can be a costly endeavor, but it can also provide long-term benefits in terms of energy savings and reducing carbon footprint. It is essential to carefully evaluate the costs and benefits before making a decision.

Are permanent magnet motors more susceptible to damage from high temperatures compared to other motor types ?

Permanent magnet motors are more susceptible to high temperatures due to demagnetization and thermal expansion issues, compared to induction motors and switched reluctance motors which primarily face insulation degradation and material fatigue respectively.

What is wind energy and how effective is it compared to other renewable sources ?

This article provides an overview of wind energy, discussing its definition, effectiveness compared to other renewable sources, cost-effectiveness, environmental impact, scalability, and availability. It highlights the benefits of wind energy as a clean and sustainable source of electricity that can be produced at any scale and in many parts of the world.

What are the main advantages of permanent magnet motors over other types of electric motors ?

Permanent magnet motors (PMMs) have several advantages over other types of electric motors, including high efficiency, low maintenance requirements, high torque density, wide speed range, and quiet operation. These advantages make PMMs ideal for a variety of applications, from small appliances to industrial machinery.

What are the key factors to consider when selecting a permanent magnet motor for a specific application ?

When selecting a permanent magnet motor for a specific application, several key factors must be considered to ensure optimal performance and efficiency. These factors include application requirements, efficiency and performance, size and weight, temperature range and cooling, control and feedback systems, cost and budget, reliability and durability, and compatibility with other system components. By carefully considering these key factors when selecting a permanent magnet motor for your specific application, you can ensure that you choose a motor that meets your needs in terms of performance, efficiency, size, cooling requirements, control options, cost, reliability, and compatibility with other system components.

How do permanent magnet motors contribute to energy savings in electric vehicles ?

Permanent magnet motors (PMMs) play a crucial role in enhancing the energy efficiency of electric vehicles (EVs). These motors are designed to convert electrical energy into mechanical energy with minimal losses, making them ideal for use in EVs. In this article, we will discuss the various ways PMMs contribute to energy savings in electric vehicles. One of the primary advantages of PMMs is their high efficiency. They can achieve up to 95% efficiency, which means that only 5% of the input energy is lost during the conversion process. This is significantly higher than other types of motors used in EVs, such as induction motors or DC motors. As a result, PMMs help reduce the amount of energy required to power an EV, leading to increased range and reduced charging times. Another benefit of PMMs is their lightweight design. Compared to traditional motors, PMMs have fewer components and require less material, resulting in a lighter overall weight. This reduction in weight helps improve the vehicle's performance by reducing its total mass and increasing its acceleration and handling capabilities. Additionally, a lighter vehicle requires less energy to move, further contributing to energy savings. PMMs also enable regenerative braking, which is a feature that allows EVs to recover some of the energy typically lost during braking. When the driver applies the brakes, the PMM acts as a generator, converting the kinetic energy of the moving vehicle into electrical energy that can be stored in the battery pack. This recovered energy can then be used to power the vehicle later on, reducing the need for additional charging and increasing the overall efficiency of the EV. Due to their simple design and lack of brushes or commutators, PMMs require less maintenance compared to other types of motors. This reduces the cost of ownership for EV owners and extends the lifespan of the motor, further contributing to energy savings over time. PMMs are capable of operating at a wide range of speeds without sacrificing efficiency. This allows EV manufacturers to design vehicles with optimal gear ratios, reducing the need for multiple gears and transmission systems. By simplifying the drivetrain, PMMs help reduce energy losses associated with complex transmissions and increase the overall efficiency of the vehicle.

Are there any emerging trends or innovations in permanent magnet motor design that could lead to performance improvements ?

Permanent magnet motors (PMMs) have been widely used in various applications due to their high efficiency, power density, and controllability. In recent years, there have been several emerging trends and innovations in PMM design that could lead to performance improvements. These include the use of high-temperature superconducting materials, advanced control strategies, integrated motor and drive systems, and the continued development of REE-free alternatives. As these technologies continue to evolve, we can expect to see even more efficient and powerful PMMs in the future.

How do I invest in wind energy projects ?

Investing in wind energy projects can be a lucrative opportunity, but requires careful consideration and planning. To ensure success, it is crucial to understand the industry, research potential projects, evaluate their feasibility and financial viability, conduct due diligence, choose a suitable investment strategy, secure financing, form partnerships, negotiate terms, monitor progress, and diversify your portfolio. By following these steps, you can make informed investment decisions and contribute to a sustainable future for generations to come.