Advantage Internal

What are the advantages of using an internal rotor motor ?

An internal rotor motor is a type of electric motor where the rotor is located inside the stator. This design has several advantages over other types of motors, such as external rotor motors or brushed motors. Some of these advantages include higher efficiency, improved heat dissipation, lower noise levels, better control and response, compact design, and reduced maintenance costs. These benefits make internal rotor motors a popular choice for various applications across industries.

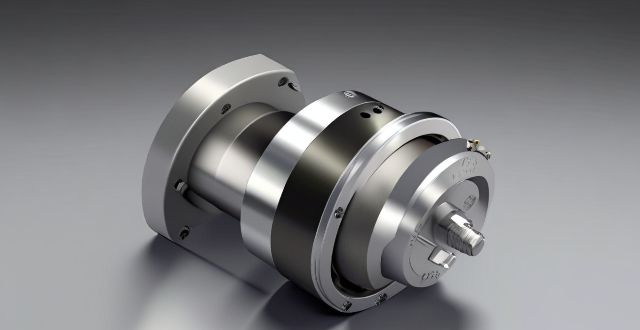

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

What are the benefits of shopping during the discount season ?

Shopping during the discount season offers numerous benefits for consumers, including saving money, getting more value for your money, trying new products, clearing out inventory, avoiding crowds, and taking advantage of promotions. By taking advantage of these opportunities, you can maximize your savings and enjoy a more enjoyable shopping experience.

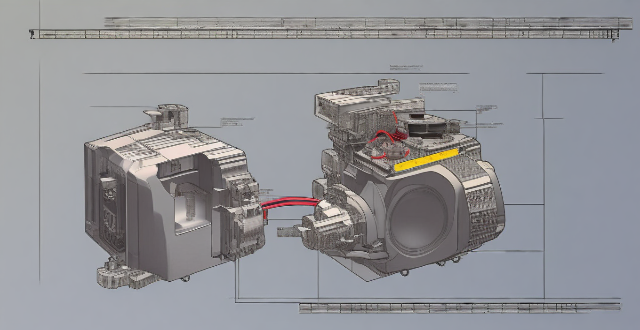

How does an internal rotor motor work ?

Internal rotor motors operate through the interaction of magnetic fields produced by their stator and rotor components, generating rotational force and torque. They offer advantages such as high efficiency and precise speed control but also have drawbacks like increased complexity and maintenance requirements.

In what applications are internal rotor motors commonly used ?

Internal rotor motors, also known as rotary motors or simply electric motors, are widely used in various applications due to their ability to convert electrical energy into mechanical energy. These motors consist of a stationary component (stator) and a rotating component (rotor), which is located inside the stator. The rotor is driven by electromagnetic forces generated by the interaction between the stator and rotor windings. In conclusion, internal rotor motors play a crucial role across numerous sectors, from industrial manufacturing to domestic appliances and even critical medical equipment. Their versatility makes them an essential component in modern technology advancements.

Is it worth taking advantage of a buy one get one free deal ?

Buy one get one free (BOGO) deals are a popular marketing strategy used by retailers to attract customers and increase sales. The pros of BOGO deals include saving money, trying new products, and stocking up on essentials. However, the cons include impulse buying, limited choices, and potential quality concerns. It is important to carefully consider the pros and cons before deciding whether to take advantage of a BOGO deal.

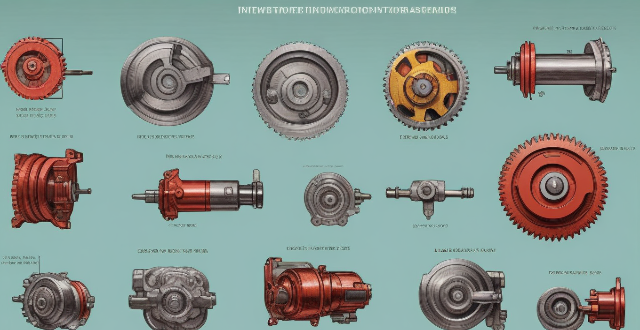

Can you explain the differences between an internal and external rotor motor ?

Motors are crucial components of various mechanical systems, and understanding their types is essential for selecting the appropriate one for a specific application. Two common types of motors are internal rotor motors and external rotor motors. An internal rotor motor has its rotor located inside the stator, while an external rotor motor has its rotor located outside the stator. The main differences between these two types of motors include rotor location, torque output, cooling efficiency, maintenance accessibility, and application suitability. Understanding these differences can help in selecting the appropriate motor type for a given task.

How do I maintain my internal rotor motor to ensure its longevity ?

Maintaining an Internal Rotor Motor for Longevity involves regular cleaning, inspection, lubrication, and checks on critical components. Proper care can extend the motor's lifespan and prevent costly repairs. Cleaning includes removing dust and debris with a soft cloth and compressed air. Deep cleaning is recommended when there are signs of overheating or reduced performance. Inspections should check for visible damage, wear, insulation resistance, and tight connections. Lubricating moving parts and changing lubricants as needed is essential. Bearings should be checked for wear and replaced if necessary, while cooling systems should be inspected for blockages or leaks. Seal integrity should also be verified. Performance testing and preventive replacement of worn parts can save time and money in the long run. Environmental considerations such as keeping the motor in a clean, dry, and temperate environment should also be taken into account. By following these steps, optimal performance and longevity of the internal rotor motor can be ensured.

How do I use cashback rewards and credit card points to my advantage when shopping ?

Using cashback rewards and credit card points can save money and get more value for purchases. To maximize benefits, choose a suitable credit card, understand the rewards program, make smart spending decisions, redeem rewards wisely, and combine them with discounts and sales.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

What are the typical故障 of an internal rotor motor, and how can they be fixed ?

Overheating, bearing failure, electrical problems, mechanical wear and tear, and improper installation are common issues with internal rotor motors. Fixes include ensuring proper ventilation and lubrication, replacing worn parts, seeking professional assistance for electrical and installation issues, and regular maintenance to prevent premature failure.

Are there any special safety precautions I should take when working with an internal rotor motor ?

The text discusses safety precautions for working with internal rotor motors. The key points include wearing appropriate personal protective equipment (PPE), disconnecting the power source before starting work, using insulated tools and gloves when working with live electrical components, using proper lifting techniques and equipment when moving heavy motors or components, avoiding contact with moving parts while the motor is running, handling lubricants or coolants carefully to avoid spills or skin contact, storing chemicals in a well-ventilated area away from heat sources and ignition sources, following proper disposal procedures for waste materials generated during maintenance or repair work, working in a well-ventilated area to minimize exposure to fumes or dust, using vacuum cleaners or other collection devices to capture debris and minimize cleanup time, and disposing of hazardous waste materials according to local regulations and guidelines.

What are the main advantages of permanent magnet motors over other types of electric motors ?

Permanent magnet motors (PMMs) have several advantages over other types of electric motors, including high efficiency, low maintenance requirements, high torque density, wide speed range, and quiet operation. These advantages make PMMs ideal for a variety of applications, from small appliances to industrial machinery.

What are the benefits of using a package forwarding service for international shopping ?

**Benefits of Using a Package Forwarding Service for International Shopping** Using a package forwarding service offers several benefits for international shoppers, including cost savings, increased shopping flexibility, potential tax and duty advantages, convenience, additional services, and peace of mind. These advantages make it easier and more efficient to shop from retailers around the globe without directly facing the complexities of international shipping.

What are the advantages of shopping for luxury goods at department stores versus boutiques ?

When it comes to shopping for luxury goods, consumersWhen it comes to shopping for luxury goods, consumers choosing between department stores and boutique there are several advantages to shopping at department stores that make them a popular choice for many luxury shoppers. These advantages include a wider variety of brands and products, one-stop shopping experiences, competitive pricing, excellent customer service, flexible return policies, loyalty programs, promotions and sales events, convenience, online shopping options, and gift registry services. Overall, department stores offer a compelling option for luxury shoppers looking for quality, value, and ease of purchase.

What role does kinetics play in the study of sports biomechanics ?

Kinetics is a key aspect of sports biomechanics, focusing on forces and motions in physical activity. It aids in understanding how athletes generate power, control movements, and enhance performance. Key points include force analysis (internal and external), energy considerations (potential, kinetic, work, and power), movement efficiency (mechanical advantage, joint reaction forces, ground reaction forces), injury prevention and rehabilitation (overuse and traumatic injuries, rehab programs), and performance optimization (technique analysis, equipment design, training methods). Overall, kinetics helps coaches, athletes, and researchers make informed decisions about training, equipment, and technique to achieve safe and effective goals.

Can CHEVs be used for long-distance travel as effectively as conventional hybrids ?

Chevrolet (CHEV) vehicles can be used for long-distance travel just as effectively as conventional hybrid vehicles. However, it's important to understand the differences between the two types of vehicles and how they operate. CHEVs (Chevrolet Hybrid Electric Vehicles) are designed to offer improved fuel efficiency and reduced emissions compared to traditional gasoline-powered vehicles. Some popular Chevrolet hybrid models include the Chevrolet Volt and Chevrolet Malibu Hybrid. Conventional hybrids, also known as self-charging hybrids, use a combination of an internal combustion engine and an electric motor to power the vehicle. Unlike plug-in hybrids, conventional hybrids do not require external charging and rely on regenerative braking and the internal combustion engine to charge their batteries. Examples of conventional hybrids include the Toyota Prius and Honda Insight. Both CHEVs and conventional hybrids are designed to offer improved fuel efficiency compared to traditional gasoline-powered vehicles. However, CHEVs may have slightly better fuel economy due to their larger battery packs and more powerful electric motors. This means that CHEVs could potentially travel farther on a single tank of gas than conventional hybrids. While both CHEVs and conventional hybrids are capable of long-distance travel, their range will depend on several factors such as driving conditions, speed, and terrain. In general, CHEVs may have a longer range due to their larger battery packs and more efficient regenerative braking systems. However, this is not always the case, and some conventional hybrids may have similar or even better range depending on the specific model and driving conditions. One potential advantage of CHEVs over conventional hybrids for long-distance travel is their shorter charging time. Since CHEVs have larger battery packs and more powerful electric motors, they can be charged faster than conventional hybrids. This means that CHEVs may be able to spend less time at charging stations during long-distance trips. Both CHEVs and conventional hybrids require regular maintenance like any other vehicle. However, since CHEVs have more complex systems with additional components such as larger battery packs and electric motors, they may have higher maintenance costs compared to conventional hybrids. This could impact the overall cost effectiveness of using CHEVs for long-distance travel.

What are the advantages and disadvantages of wind energy ?

The given text is about the advantages and disadvantages of wind energy. The advantages include being renewable and sustainable, environmentally friendly, cost-effective, job creation, and energy independence. On the other hand, the disadvantages are its intermittent nature, land use concerns, noise and visual impact, wildlife impact, and high initial cost.

What are some red flags that might discourage investors from funding my startup ?

Investors look for signs that a startup may not be a good investment. Here are some common red flags: 1. **Lack of a Clear Business Model**: Undefined revenue streams, no competitive advantage, ignoring market research, and underestimating costs can discourage investors. 2. **Poor Financial Management**: Lack of financial projections, inadequate funding, high burn rate, and unrealistic valuation raise concerns. 3. **Weak Team Dynamics**: A lack of diversity, inexperienced leadership, high turnover rates, and poor communication within the team or with investors are problematic. 4. **Legal and Ethical Concerns**: Intellectual property disputes, regulatory non-compliance, and ethical issues can deter investors. 5. **Product and Technology Issues**: Technological limitations, scalability problems, and a lack of innovation are major concerns. 6. **Market and Sales Challenges**: A small addressable market, saturated markets, and sales execution risks can make investors hesitant.

How can small and medium-sized enterprises adopt clean production technologies ?

In this article, we explore the crucial role of small and medium-sized enterprises (SMEs) in adopting clean production technologies to mitigate environmental impacts while maintaining profitability. Clean production technologies include energy-efficient machinery, low-emission processes, recycling, water conservation techniques, and more. SMEs face challenges such as lack of awareness, high initial costs, skill gaps, and market uncertainty. However, strategies like government incentives, collaboration with industry associations, education and training, incremental adoption, partnerships with research institutions, technology audits, and digital transformation can help overcome these challenges. Adopting clean production technologies offers benefits for SMEs, including cost savings, competitive advantage, regulatory compliance, and brand reputation enhancement. As society moves towards a more sustainable future, the role of SMEs in adopting clean production technologies will become increasingly vital.

How do parallel hybrid electric vehicles (PHEVs) compare to traditional gasoline cars in terms of performance ?

Parallel Hybrid Electric Vehicles (PHEVs) offer better acceleration and fuel efficiency than traditional gasoline cars but may have lower top speeds and require more time for recharging. Gasoline cars have higher top speed capabilities and quicker refueling but are less efficient and require more maintenance. The choice between the two depends on individual needs and preferences.

What are the alternatives to fossil fuels for energy production ?

The article discusses various alternatives to fossil fuels for energy production, including solar energy, wind energy, hydroelectric power, geothermal energy, biomass energy, and nuclear energy. It explains the working principles of each alternative and their advantages and disadvantages. The main advantage of these alternatives is that they produce clean energy with minimal greenhouse gas emissions, reducing the impact on the environment and climate change. However, some of them require significant investment and infrastructure development, while others have safety concerns or limited availability. Overall, the article highlights the potential of these alternatives in providing sustainable and reliable sources of energy for the future.

Are there any tax incentives for buying a hybrid car ?

The text discusses the tax incentives available for buying a hybrid car, including federal and state tax credits and other benefits such as fuel efficiency and reduced maintenance costs. It also emphasizes the importance of researching specific requirements and limitations before making a purchase decision.

How efficient is wind energy compared to other renewable sources ?

The efficiency of wind energy is influenced by factors such as capacity factor, technological advancements, and site specificity. Compared to other renewable sources like solar, hydropower, geothermal, biomass, and tidal/wave energy, wind energy has a relatively high capacity factor ranging from 35% to 45%. Technological improvements have increased the efficiency of wind turbines over the years, making them more productive. However, the efficiency of wind farms is highly dependent on the location, with optimal sites achieving higher efficiency rates. In conclusion, wind energy compares favorably to other renewable sources in terms of efficiency, but the choice between different renewable energies often depends on local conditions, economic factors, and technological advancements.