Appliance Internal

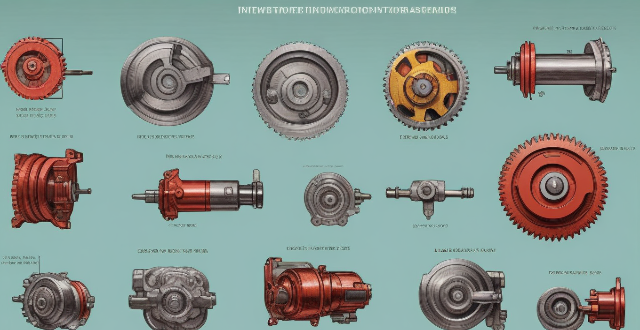

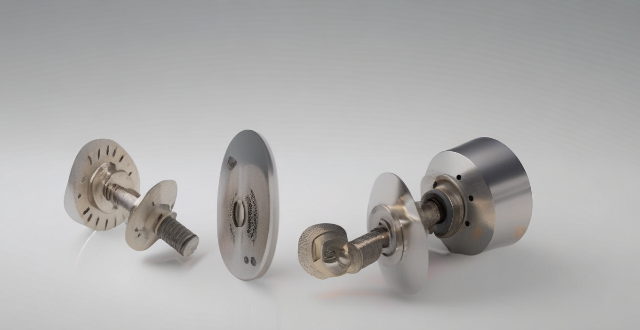

What is an internal rotor motor ?

The text discusses the design, advantages, disadvantages, and applications of internal rotor motors. Internal rotor motors are a type of electric motor where the moving part (rotor) is inside the stationary part (stator). They offer benefits such as high efficiency, good heat dissipation, simplicity in construction, and low inertia. However, they also have limitations like limited torque density, difficulty in cooling, and potential for magnetic saturation. These motors are commonly used in automotive, aerospace, industrial equipment, and consumer electronics applications.

How can I save energy with appliance usage at home ?

The provided text offers energy-saving tips for various home appliances, including refrigerators, dishwashers, washing machines, dryers, ovens and cooktops, lighting, and thermostats. It suggests setting the fridge temperature correctly, defrosting it regularly, and keeping it full but not overstuffed. For dishwashers, it recommends running full loads and using the energy-saving setting. Washing machines should be used with cold water and the appropriate wash cycle. Dryers should have a clean lint filter after each use and dry similar fabrics together. Smaller appliances should be used for small meals when cooking, and the oven door should remain closed. LED bulbs should replace traditional incandescent bulbs, and lights should be turned off when not in use. A programmable thermostat should be used to set specific temperatures for different times of the day, and the temperature should be lowered in winter and raised in summer. Following these tips can significantly reduce home energy consumption, save money on utility bills, and contribute to a more sustainable environment.

What are the advantages of using an internal rotor motor ?

An internal rotor motor is a type of electric motor where the rotor is located inside the stator. This design has several advantages over other types of motors, such as external rotor motors or brushed motors. Some of these advantages include higher efficiency, improved heat dissipation, lower noise levels, better control and response, compact design, and reduced maintenance costs. These benefits make internal rotor motors a popular choice for various applications across industries.

What is the efficiency rate of an internal rotor motor compared to other types of motors ?

The efficiency rate of an internal rotor motor compared to other types of motors depends on various factors such as design, size, application, materials, and control system. Internal rotor motors typically have higher efficiency rates than external rotor motors due to their compact design and reduced air gap between the rotor and stator. However, it is essential to consider the specific requirements of the application when choosing a motor type, as other factors such as brushless DC (BLDC) motors and permanent magnet synchronous motors (PMSM) are also known for their high efficiency rates.

How can I use kitchen appliances to save time while cooking ?

Using kitchen appliances like food processors, slow cookUsing kitchen appliances like food processors, slow cookers, rice cookers, slow cookers, electric pressure cookers, rice cookers, and stand mixers can significantly save time in meal preparation. These appliances offer features such as chopping, grinding, making dough, cooking at different heat settings, and precise mixing, allowing for efficient and convenient cooking experiences.

What is the best way to clean and maintain stainless steel kitchen appliances ?

Stainless steel kitchen appliances require proper cleaning and maintenance to keep them looking their best. To clean them, gather materials such as a microfiber cloth, mild dish soap, water, white vinegar, baking soda, and olive or mineral oil for polishing. The cleaning process involves removing grease and stains with a damp cloth, rinsing and drying the surface, removing stubborn stains with a baking soda paste, and polishing the surface with oil. In addition to regular cleaning, maintenance tips include avoiding harsh chemicals and abrasive cleaners, using a gentle touch when cleaning, keeping appliances away from direct sunlight and heat sources, and using protective covers when not in use.

How does an internal rotor motor work ?

Internal rotor motors operate through the interaction of magnetic fields produced by their stator and rotor components, generating rotational force and torque. They offer advantages such as high efficiency and precise speed control but also have drawbacks like increased complexity and maintenance requirements.

In what applications are internal rotor motors commonly used ?

Internal rotor motors, also known as rotary motors or simply electric motors, are widely used in various applications due to their ability to convert electrical energy into mechanical energy. These motors consist of a stationary component (stator) and a rotating component (rotor), which is located inside the stator. The rotor is driven by electromagnetic forces generated by the interaction between the stator and rotor windings. In conclusion, internal rotor motors play a crucial role across numerous sectors, from industrial manufacturing to domestic appliances and even critical medical equipment. Their versatility makes them an essential component in modern technology advancements.

What is the relationship between energy-efficient appliances and overall energy savings ?

The text discusses the connection between energy-efficient appliances and overall energy savings, defining such appliances as those engineered to meet specific efficiency standards. These devices reduce direct energy consumption through lower power requirements and advanced technology, leading to long-term cost benefits and environmental advantages like reduced greenhouse gas emissions. To maximize savings, consumers should research and maintain these appliances properly and replace older models. The relationship underscores the importance of energy-efficient appliances in achieving energy savings for a more sustainable future.

Can you explain the differences between an internal and external rotor motor ?

Motors are crucial components of various mechanical systems, and understanding their types is essential for selecting the appropriate one for a specific application. Two common types of motors are internal rotor motors and external rotor motors. An internal rotor motor has its rotor located inside the stator, while an external rotor motor has its rotor located outside the stator. The main differences between these two types of motors include rotor location, torque output, cooling efficiency, maintenance accessibility, and application suitability. Understanding these differences can help in selecting the appropriate motor type for a given task.

How do I maintain my internal rotor motor to ensure its longevity ?

Maintaining an Internal Rotor Motor for Longevity involves regular cleaning, inspection, lubrication, and checks on critical components. Proper care can extend the motor's lifespan and prevent costly repairs. Cleaning includes removing dust and debris with a soft cloth and compressed air. Deep cleaning is recommended when there are signs of overheating or reduced performance. Inspections should check for visible damage, wear, insulation resistance, and tight connections. Lubricating moving parts and changing lubricants as needed is essential. Bearings should be checked for wear and replaced if necessary, while cooling systems should be inspected for blockages or leaks. Seal integrity should also be verified. Performance testing and preventive replacement of worn parts can save time and money in the long run. Environmental considerations such as keeping the motor in a clean, dry, and temperate environment should also be taken into account. By following these steps, optimal performance and longevity of the internal rotor motor can be ensured.

What impact do energy-efficient appliances have on reducing electricity bills ?

Energy-efficient appliances can significantly reduce electricity bills by using less energy and incorporating smart features. These appliances may have higher upfront costs, but the long-term cost savings often outweigh the initial investment. Additionally, energy-efficient appliances contribute to a smaller carbon footprint and conserve energy resources, promoting sustainability. Overall, these appliances offer financial and environmental benefits for conscious consumers.

Is it possible to convert an internal rotor motor into an external rotor one, and vice versa ?

Converting an internal rotor motor into an external rotor one and vice versa is possible but not straightforward. It requires significant modifications to the motor's design and components, which can be costly and time-consuming. Moreover, the performance of the converted motor may not meet the original specifications or expectations. Therefore, it is essential to carefully evaluate the benefits and drawbacks of such a conversion before proceeding.

What are the typical故障 of an internal rotor motor, and how can they be fixed ?

Overheating, bearing failure, electrical problems, mechanical wear and tear, and improper installation are common issues with internal rotor motors. Fixes include ensuring proper ventilation and lubrication, replacing worn parts, seeking professional assistance for electrical and installation issues, and regular maintenance to prevent premature failure.

Are there any special safety precautions I should take when working with an internal rotor motor ?

The text discusses safety precautions for working with internal rotor motors. The key points include wearing appropriate personal protective equipment (PPE), disconnecting the power source before starting work, using insulated tools and gloves when working with live electrical components, using proper lifting techniques and equipment when moving heavy motors or components, avoiding contact with moving parts while the motor is running, handling lubricants or coolants carefully to avoid spills or skin contact, storing chemicals in a well-ventilated area away from heat sources and ignition sources, following proper disposal procedures for waste materials generated during maintenance or repair work, working in a well-ventilated area to minimize exposure to fumes or dust, using vacuum cleaners or other collection devices to capture debris and minimize cleanup time, and disposing of hazardous waste materials according to local regulations and guidelines.

What technologies are being developed to help reduce carbon footprint ?

The text discusses various technologies being developed to help reduce carbon footprint, including renewable energy sources such as solar, wind, hydro, and geothermal power; electric vehicles (EVs) with improving battery technology and charging infrastructure; energy efficiency through building design, appliance efficiency, and smart grids; carbon capture and storage (CCS); and nuclear power. These technologies aim to combat climate change by reducing greenhouse gas emissions and promoting sustainable practices.

How can I ensure electrical safety in my home ?

Electrical safety is crucial for maintaining a secure home environment. Hire licensed electricians, schedule inspections, keep appliances clean, avoid overloading outlets, be cautious around water, childproof your home, use proper lighting, keep flammable materials away from electrical appliances, and know how to shut off power in emergencies.

What are the most popular items to buy on Black Friday ?

Black Friday is a shopping holiday known for its significant discounts on various products. The most popular items to buy on this day include electronics like TVs, laptops, smartphones, and gaming consoles; home appliances such as kitchen appliances, large appliances, and vacuum cleaners; clothing and accessories from fashion brands, shoes, and jewelry; toys and games including Lego sets, board games, and video games; and sports and fitness equipment like other sports gear and fitness trackers. It's important to be strategic in what you buy and look out for early bird specials and doorbuster deals to save even more money.

How does a home energy audit help in saving on electricity ?

A home energy audit helps identify inefficiencies and suggests upgrades, leading to electricity savings. It includes checks on insulation, air leakage, ductwork, appliance efficiency, and lighting systems. It also promotes behavioral changes and renewable energy options, providing a prioritized plan for improvements along with information on financial incentives.

What impact does climate awareness have on global policies and decisions ?

Climate awareness has led to the implementation of various environmental, economic, and social policies at national and international levels. These policies aim to reduce greenhouse gas emissions, promote renewable energy sources, protect forests, and raise public awareness about climate change. Some examples include carbon taxes, renewable energy targets, forest protection laws, the Paris Agreement, the Kyoto Protocol, cap-and-trade systems, feed-in tariffs, tax credits for renewable energy projects, building codes, appliance standards, school curricula on climate change, and community workshops.

What safety precautions should be followed in kitchens to avoid fires ?

To prevent kitchen fires, essential safety measures include keeping flammable materials away from heat sources, cleaning up spills immediately, not leaving cooking unattended, installing working smoke alarms, and having a fire extinguisher accessible. Cooking safety tips involve using appropriate cookware, watching pot lids, avoiding overfilling pots with oil, and setting timers for cooking. Electrical appliance safety requires unplugging unused appliances, inspecting cords regularly, and avoiding damaged plugs or outlets. Gas stove safety includes checking for gas leaks, keeping flammable objects away from burners, and having gas lines professionally inspected annually. Maintenance and cleanliness are also crucial, such as cleaning range hood filters, ovens, and disposing of grease properly.

How can climate and environmental policies be integrated with other policy areas, such as transportation, energy, and agriculture ?

The text provides an overview of how climate and environmental policies can be integrated with other policy areas, focusing on transportation, energy, agriculture, and cross-sector collaboration. In transportation, promoting sustainable systems includes investing in public transportation, electric vehicles, and biking/walking paths, while encouraging green commuting habits involves telecommuting and carpooling. In the energy sector, transitioning to renewable sources involves setting standards, offering subsidies, and investing in R&D, while improving efficiency includes stricter building codes and appliance standards. In agriculture, sustainable practices involve organic farming and water management, while reducing methane emissions includes better livestock management and using anaerobic digesters. Cross-sector collaboration emphasizes policy coordination, research and innovation, and financing and investment strategies. The conclusion highlights the importance of a comprehensive approach that combines regulatory measures, financial incentives, educational campaigns, and collaborative efforts for creating a more sustainable future.

In which industries are permanent magnet motors most commonly used ?

Permanent magnet motors are utilized across a wide range of industries due to their efficiency and reliability. Key sectors include the automotive industry, where they power electric and hybrid vehicles and are used in automated manufacturing. In aerospace and defense, PM motors are crucial for aircraft systems and military applications. Appliance manufacturing benefits from PM motors in household and commercial equipment. The medical sector employs them in imaging equipment and surgical tools. Manufacturing and process control use PM motors in CNC machinery and pumps/valves. Renewable energy sectors such as wind turbines and solar tracking systems also rely on these motors. Consumer electronics, including audio and visual equipment as well as toys and hobbyist products, make use of permanent magnet motors for various functions.

What are some popular items currently on sale ?

Popular items currently on sale include TVs, smartphonesPopular items currently on sale include TVs, smartphones consoles, kitchen appliances, smartphones, laptops, gaming consoles, kitchen appliances, cleaning devices, large appliances, clothing, handbags, shoes, jewelry, sports gear, camping gear, outdoor activities, educational toys, building sets, board games, and puzzles.

What are the current climate policies in place to address global warming ?

The text discusses various current climate policies aimed at addressing global warming, including national and international agreements and corporate actions. National policies focus on renewable energy initiatives, carbon pricing mechanisms, energy efficiency standards, and deforestation reduction. International agreements like the Paris Agreement and Kyoto Protocol set targets for greenhouse gas emissions reductions. REDD+ provides financial incentives for reducing deforestation. Corporate actions involve CSR initiatives and carbon offsetting programs to minimize environmental impact.